| Home | | Weekly Assignments | | Final Project | | Photo Gallery |

Week 9 & 10

Mechanical and machine designing

Machine designing week is one of the most intersting weeks in the entire Fab Academy. 5 members are doing Fab Academy from Fablab Kochi and we worked as a group on this single project.

Our Team

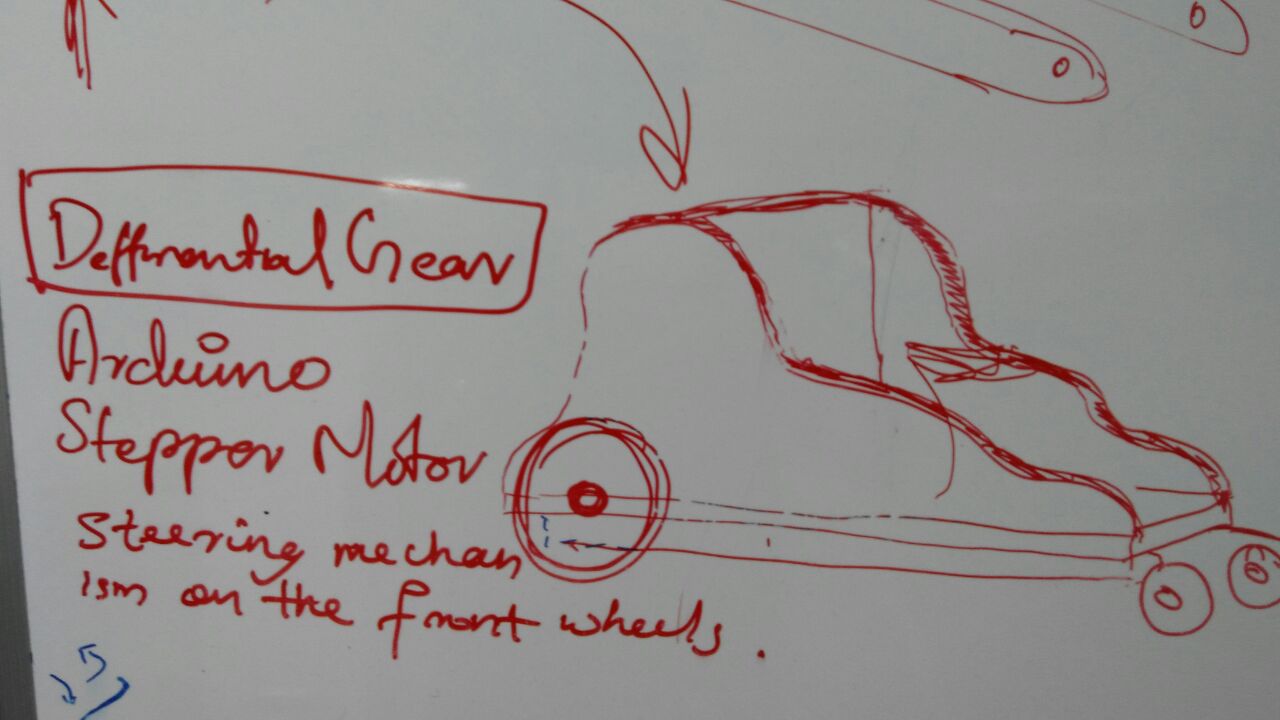

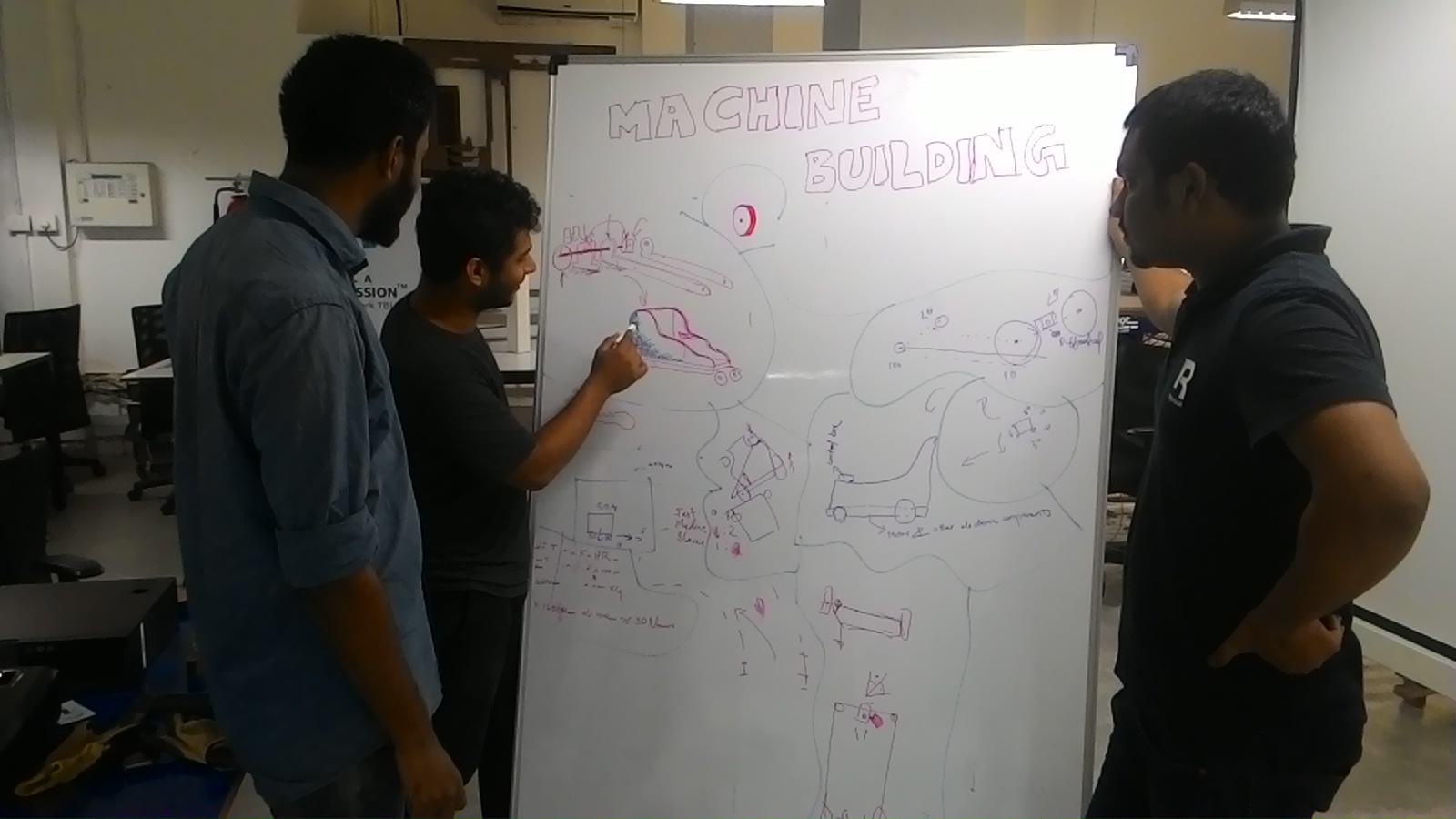

The idea was to brainstorm and come up with some cool project idea which can be implemented making use of the things we learned in the previous work at Fab Academy. We decided to make a low lying wheel chair which can be used by handicapped children to travel around.

A basic rough design was drawn on the whiteboard by Athif. We instantly agreed to go ahead with this particular design. We also decided to keep a frugal budget for doing this particular project.

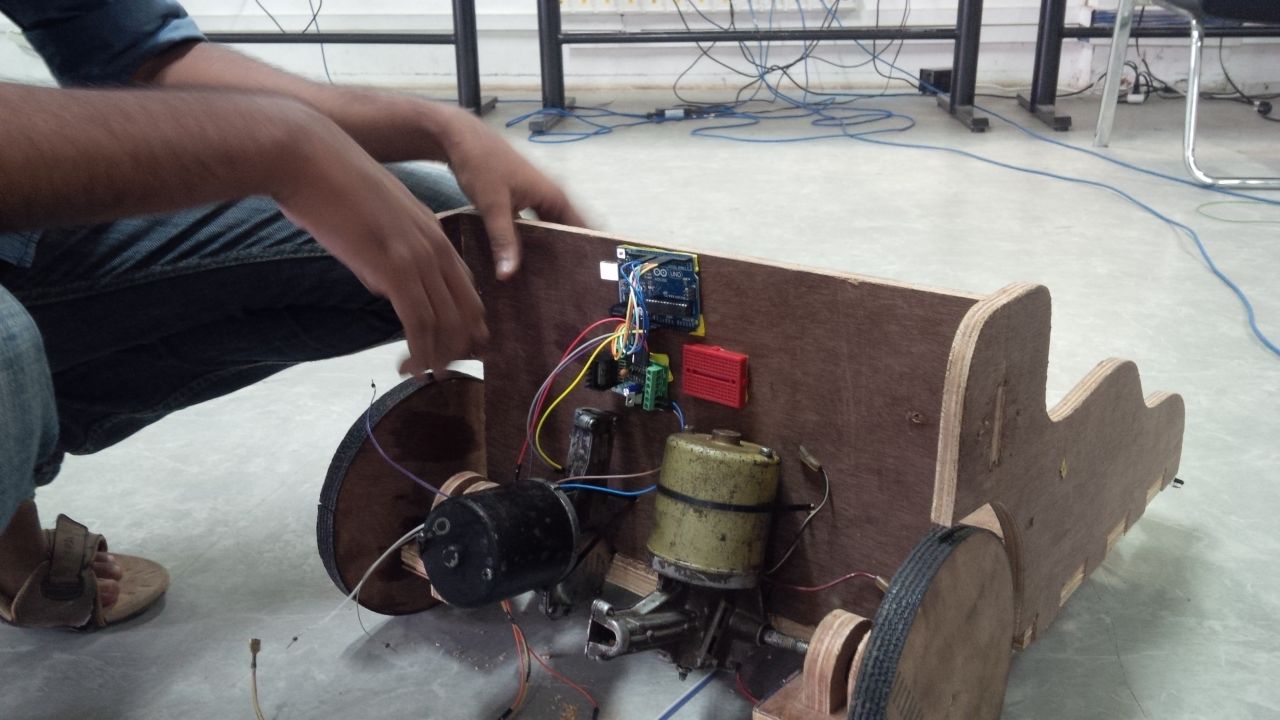

The project was completed as a team effort. The video below show our project scrapbot in action.

My contribution

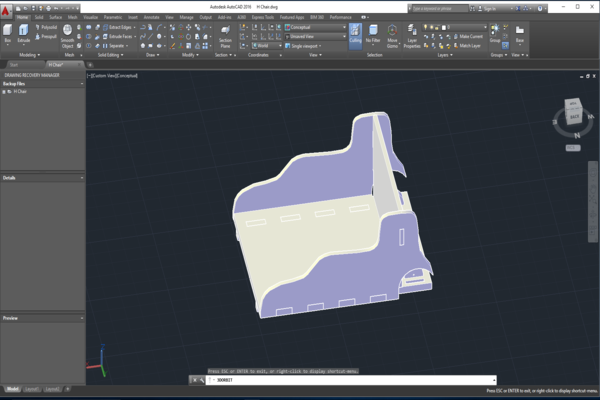

Five of us worked on this project. The responisbilities were split equally between all team members. Athif managed the designing part, Riyas took the responsibility of getting all the mechanicals right, Nizam and Arsheena worked on the electronics part and as I manage the activities at our FabLab, I took the responsibility of managing the entire project development and coordination.

It was my job to source all the things needed to complete this project. To keep it frugal, we used only the left over consumables available in Fab Lab and other scrap material. So we decided to name this project Scrapbot.

So we went back to the drawing board to figure out ways to complete this project without letting go the things we developed so far.

View the details of the project on our group project page