Step1

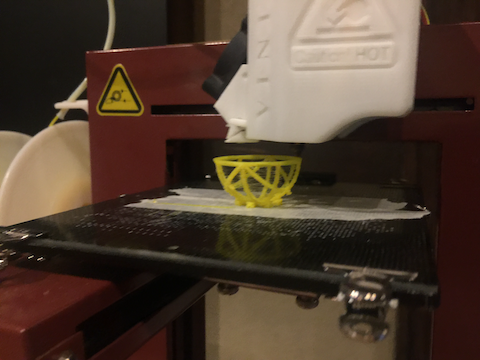

Print out

MachineMachine is AFINIA. I used first time.

Data was send from PC to AFINIA.

Design rule

This printer can be made 15x15x15cm (XxYxZ)

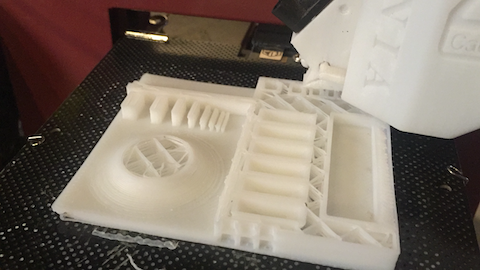

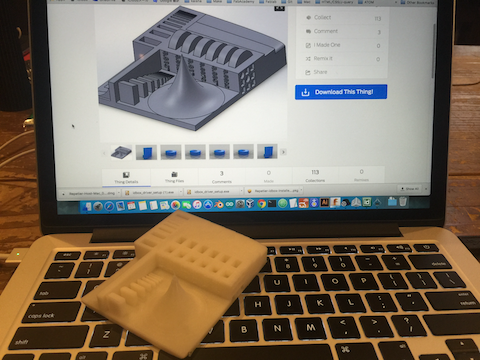

Fist printing

I used existing data from thingiverse.

3D Printer Tolerance Test

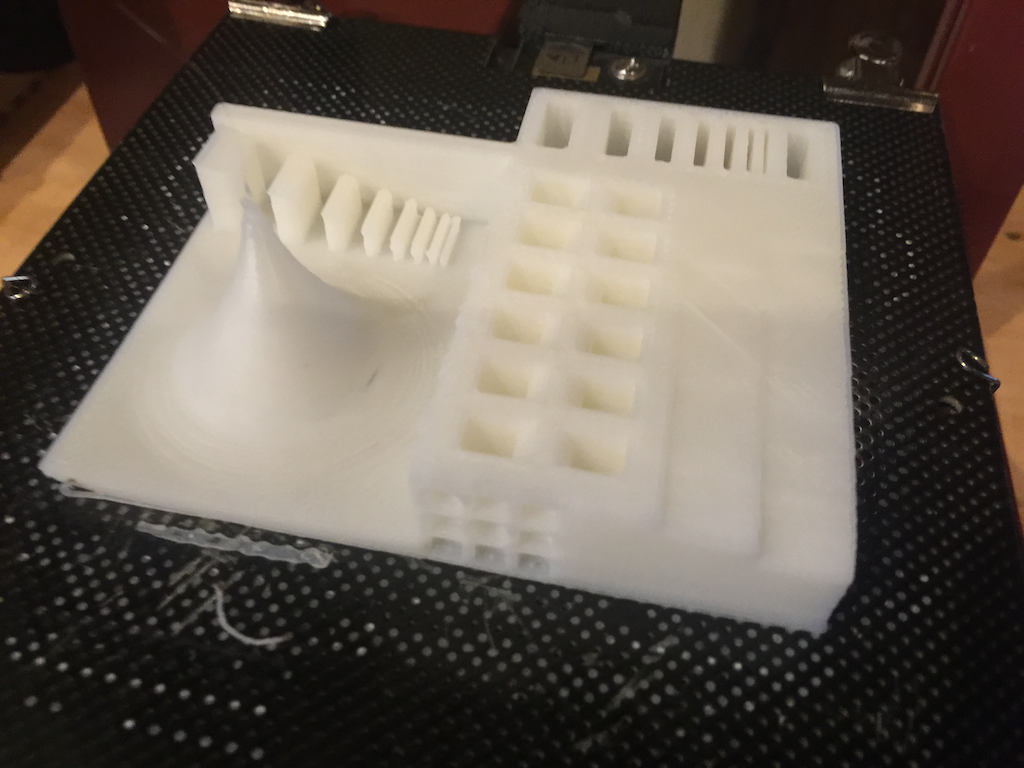

AFINI could not make small holes in left side.

Some characters were not created on wall.

When it was make bottom base. One corner was ditorted.

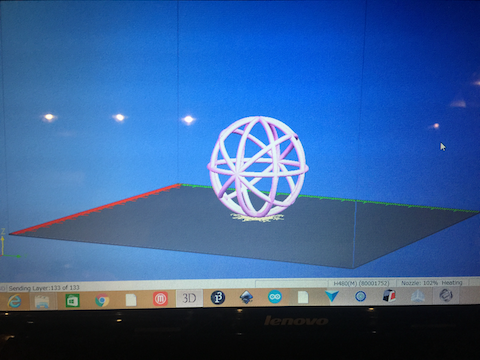

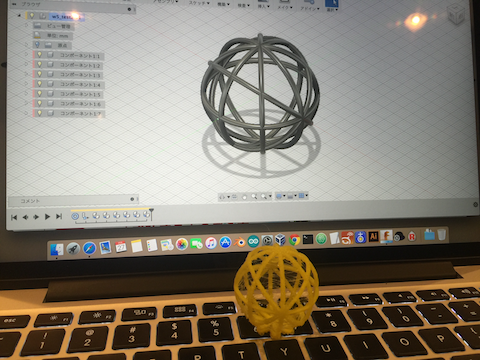

Second step

Made small cube form 7rings

Data:test_ball.stl

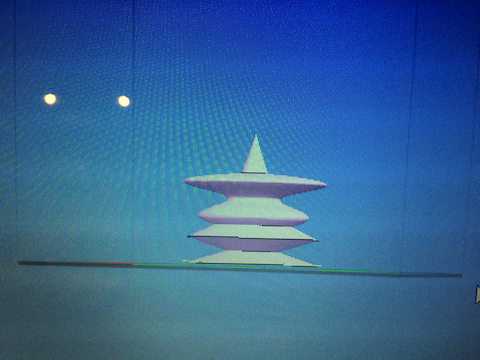

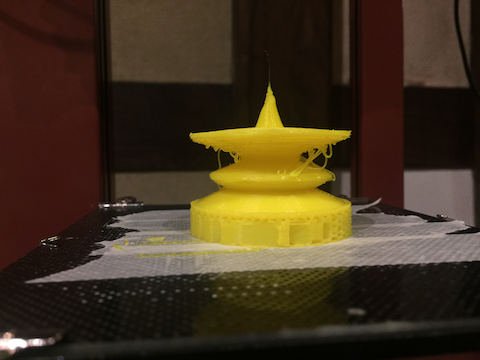

Third step

Print of diagonal shape

Data:test_object.stl

Step2

3D scan

MachineMachine is SENSE.

I isntalled original software for SENSE to my pc.

I scaned my mouse. But mouse is too small for SENSE.

SENSE could not scan it.

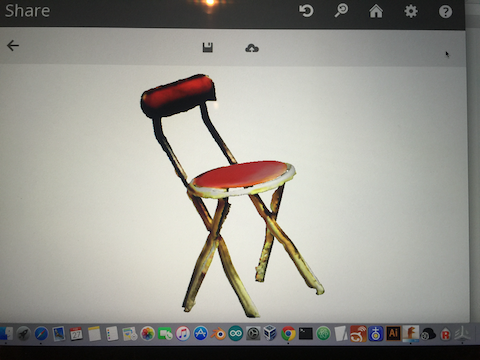

I selected chair. see below pictures.

SENSE can scaned it.

Data:Scaned_chair.stl

This scaning machine can not scan small size.

Belows are tested items.