Molding and Casting

The goal of this week is to:

Create a Mold

Cast a Part

Plan

Make a tool for the final project.

I am going to cast a part to be used on the shelf.

The shelf will hold tools, so I am going to cast a holder for pliers.

Trace a real pair of pliers using CorelDraw.

Use that sketch outline(SVG) to create a millable image.

Mill the pliers using CNC machine.

Choose a soft (semi-rigid) plastic to cast.

Process

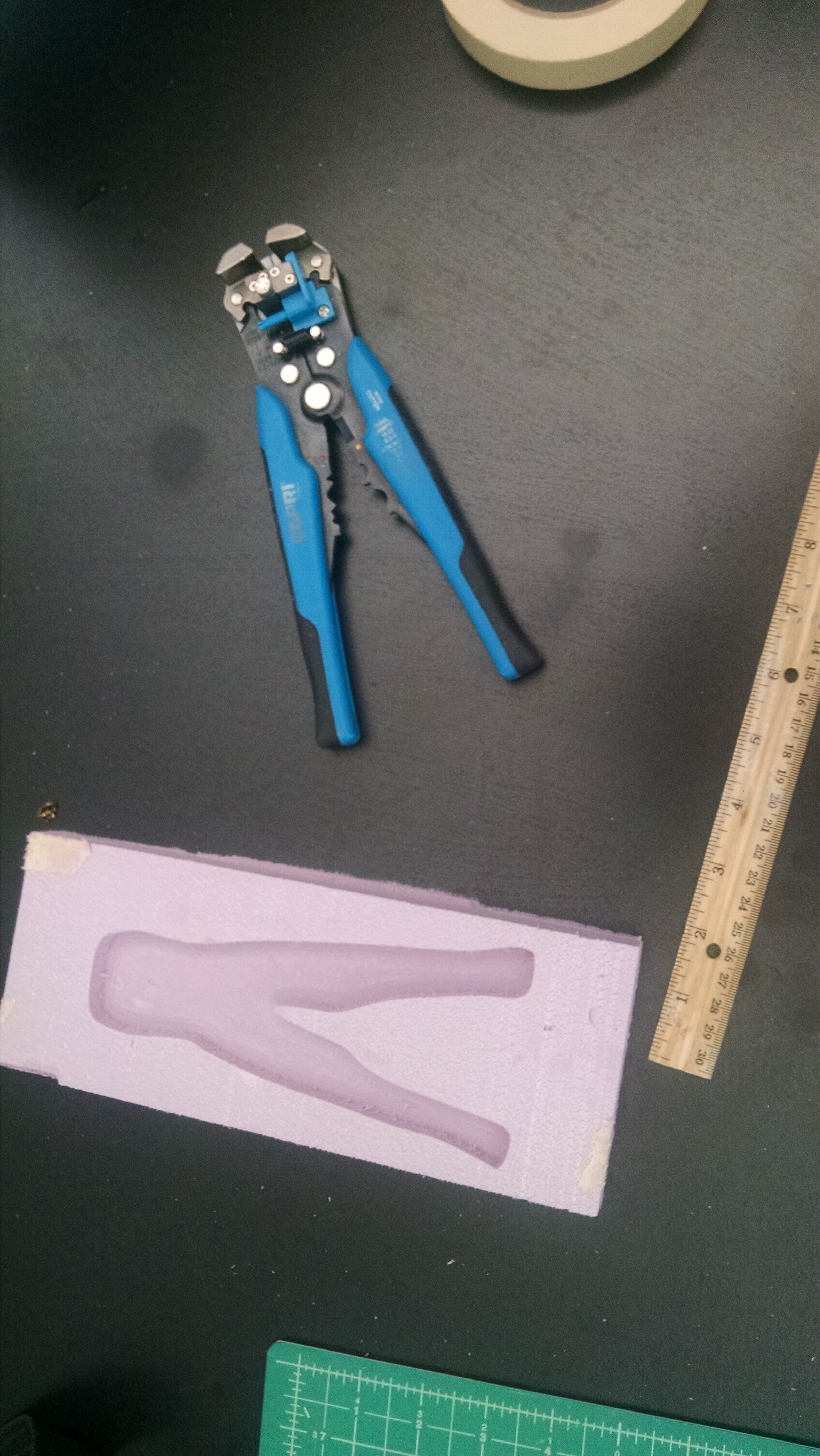

This is the starting image:

.jpg) These are the SVGs:

These are the SVGs:

The SVG were imported into Easel. Easel generated the gcode. I attached pink foam to the

wasteboard of the CNC mill(Carvey) using the clamps and tape.

The SVG were imported into Easel. Easel generated the gcode. I attached pink foam to the

wasteboard of the CNC mill(Carvey) using the clamps and tape.

I choose the correct material type and the

correct size for the material.

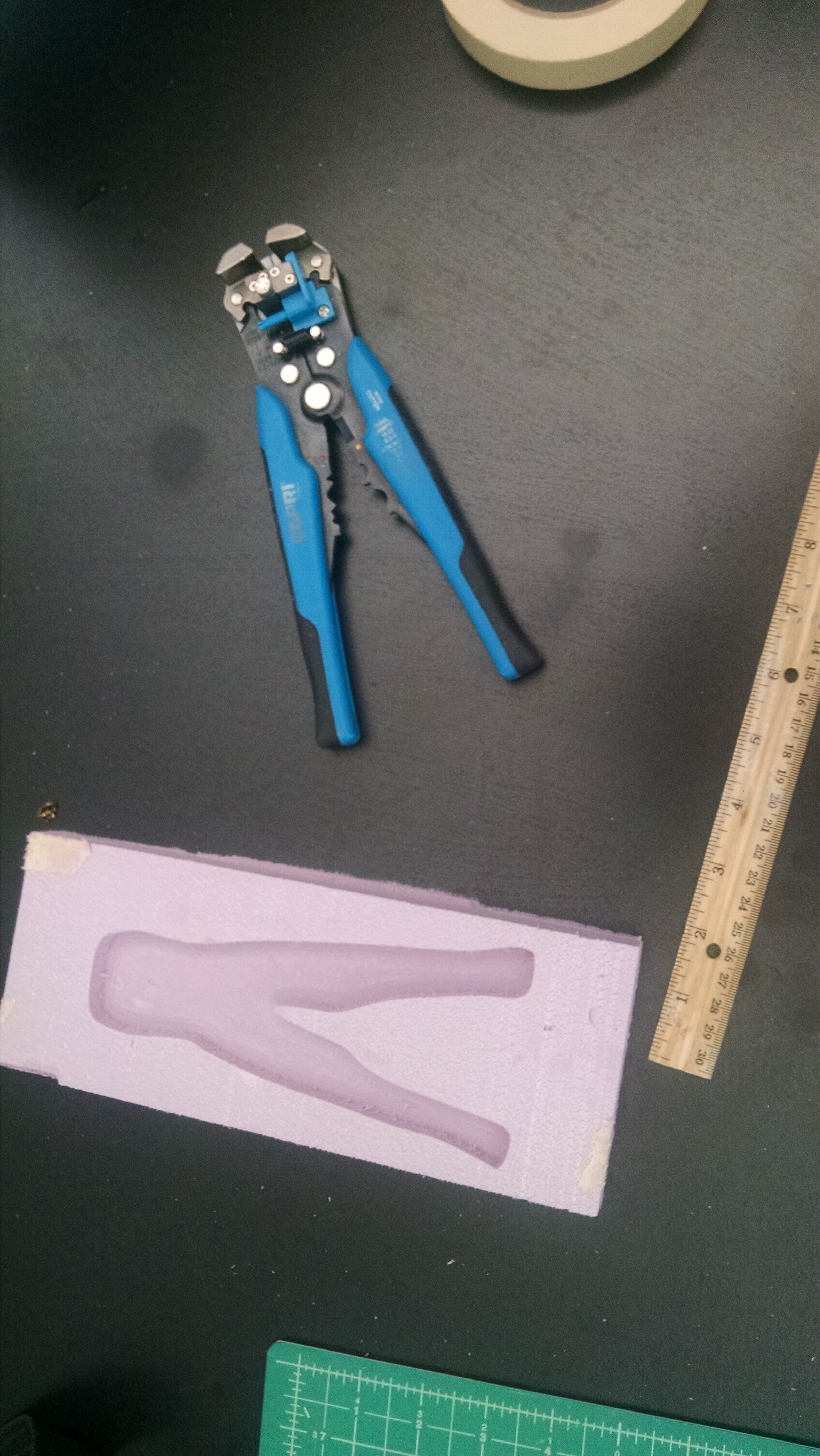

This is the milled mold:

This mold was used to check the size.

This mold was used to check the size.

After confirming the size, the reverse mold was made.

After confirming the size, the reverse mold was made.

This is the cast plastic:

This is the cast plastic:

To cast, I chose Smooth-Cast 326. It is a semi rigid material.

I should have cast first with a silicone mold. This would have made a better mold.

The mold is not very smooth.

To cast, I chose Smooth-Cast 326. It is a semi rigid material.

I should have cast first with a silicone mold. This would have made a better mold.

The mold is not very smooth.

I tried several things as a releasing agent. Petroleum Jelly worked best.

Universal Mold Release worked as well, but the rough parts of the mold still

show up in the mold. No releasing agent left a bumpy surface.

.jpg) These are the SVGs:

These are the SVGs: This mold was used to check the size.

This mold was used to check the size. After confirming the size, the reverse mold was made.

After confirming the size, the reverse mold was made. This is the cast plastic:

This is the cast plastic: To cast, I chose Smooth-Cast 326. It is a semi rigid material.

I should have cast first with a silicone mold. This would have made a better mold.

The mold is not very smooth.

To cast, I chose Smooth-Cast 326. It is a semi rigid material.

I should have cast first with a silicone mold. This would have made a better mold.

The mold is not very smooth.