Molding and casting.

Twelfth week

The objective of this week was to crate a mold for a silicon casting.

I'm thinking about making a chocolate mold, so my first necessity was the inspiration. After a lot of different subjects, I chose one that inspired me a lot: Crystals!

However, make a structure like that is impossible with one plate. But to see how I can do that we can just see the chocolate eggs process.

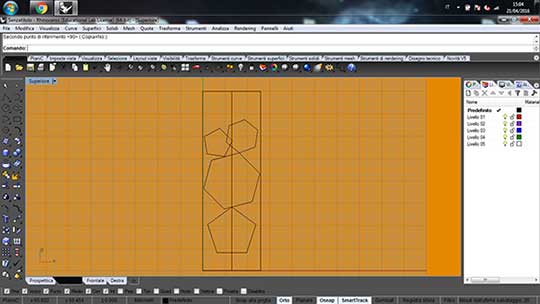

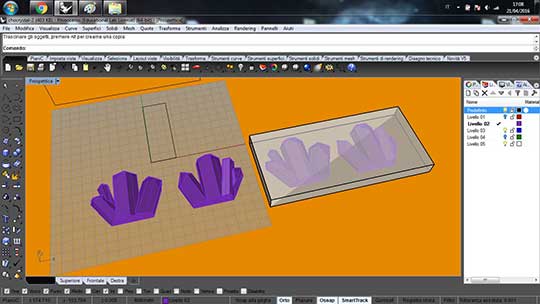

So, the next step to make chocolate crystals was the 3D drawing.

I made a polygonal base and I extruded the crystals. Be sure to consider the work area dimensions!

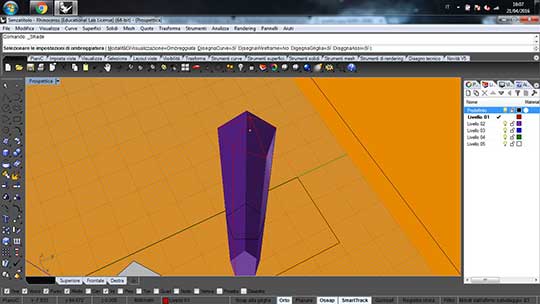

To make a realistic structure I cutted some "walls" to make an irregular shape.

Files here: Rhino and STL.

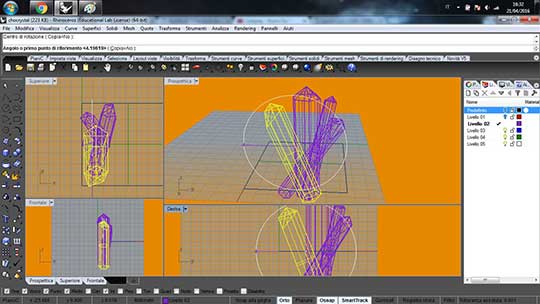

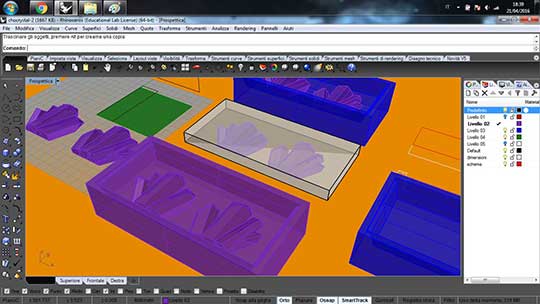

When all crystals was done I rotate them in different angles. I made a 2D wall to split the structure in half.

An important passage was setting the top of all crystal structures in the middle of the cut. Because the mill cannot cut in negative (obviously).

At this point I fused and divided the crystals in two parts, than I made a little test of the work area.

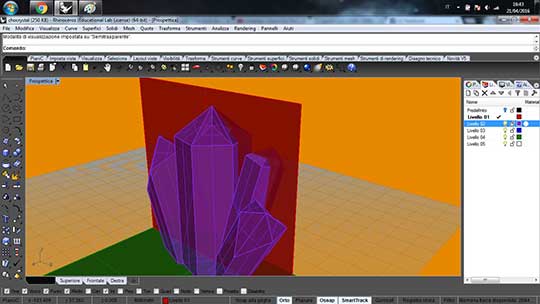

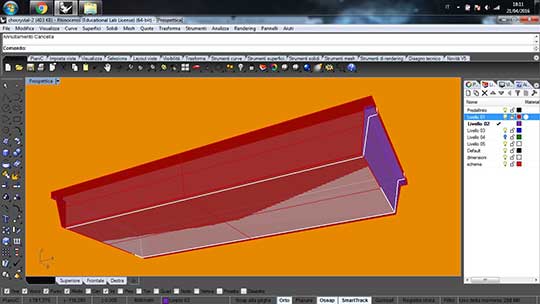

With most accurate quotes I made a solid with the negative form that I will give to the area. And subtracted it (with boolean mode) at the wax brick.

Than I made the final adjustment and reduced, with a 3D scale, the both crystal faces a little. To be sure that the mill can work safetly.

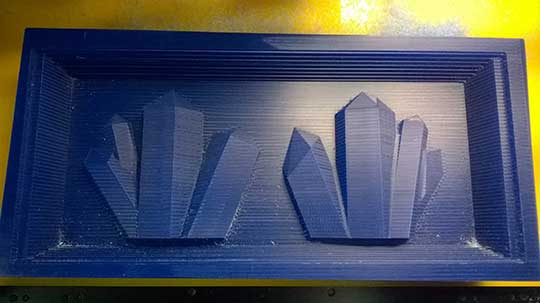

The milling machine was the Roland. To mold the wax we have to make two passages: rough and finishing. I set the parameters in this way:

For rough/finishing process:

XY speed: 20/24

Z speed: 10

Spindle: 7.000

Cutting amount: 0,6/0,2

Path interval: 1,3/0,6 (this parameter must be lower than the half of the tip)

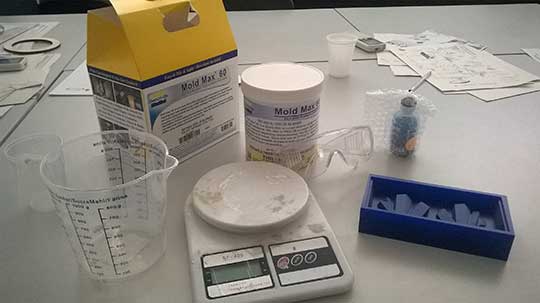

At this point I must start with the silicon preparation!

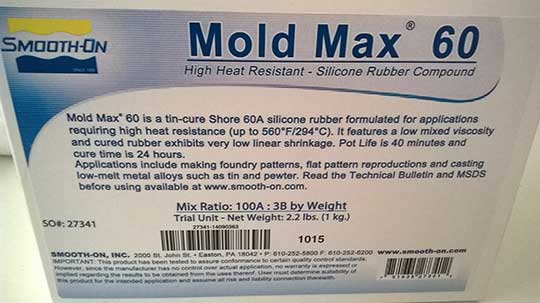

For unknown reasons the package delivered was different from the package requested, however I prepared it aniway (after reading instructions).

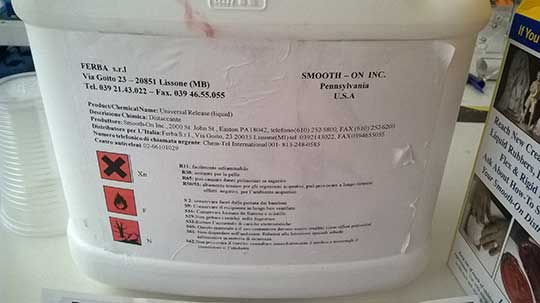

I covered the wax surface with an non-sticking substance.

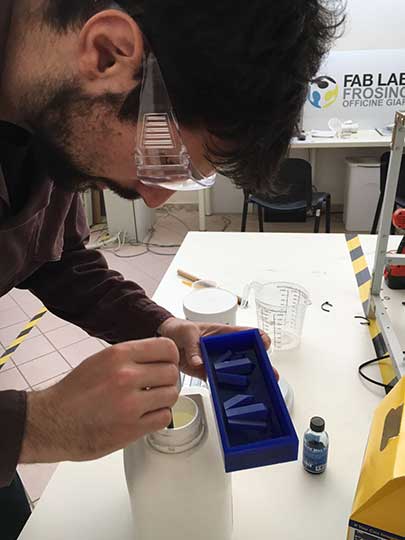

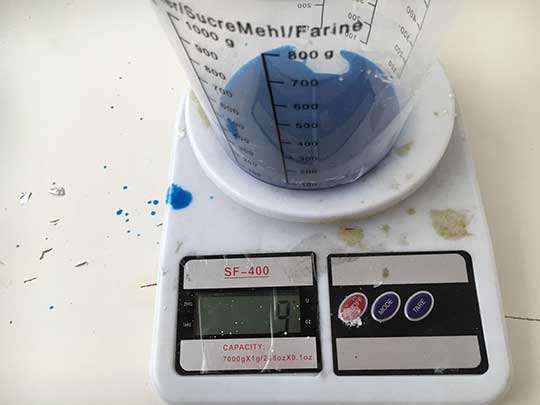

The two substances of silicon must be mixed with a weight proportion of 100%/3%.

After 3/4 minutes of mixing I finally filled the wax mold with the mixture.

An important passage of the process was the "slamming" of the mold on the table, to avoid the bubbles formation.

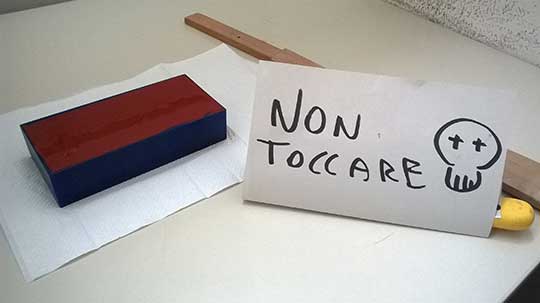

Now I have to wai at least 24 hours. Don't touch!!!

After (at least) 24 hours, this silicon must be cooked for 4/5 hours with a 51°C heat.

With all this passages the mold is ready, and we can finally cast the chocolate!

Few minutes later we can finally enjoy the "chocrystals"!

I've asked to my dear friend Federica, from ILDE creations, to make a soap too with my mold. She's an artist who made manifacrture production, from tailoring to soap creation.

And is is the result: a "Cryptonite soap"!!!

Copyleft © Alessandro Patrizi 2016