Machine Design.

Tenth week

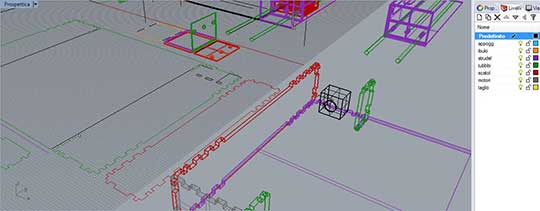

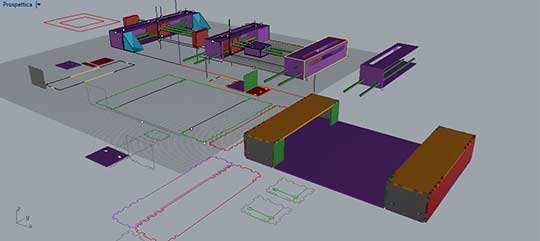

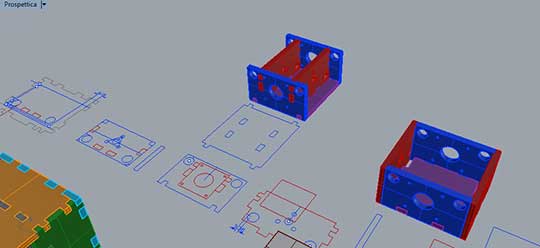

This week I changed 3D files to make a wood version of the machine.

To make a most powerful stability, I opted for an unique structural base.

I changed all thickness parameters to 2.54 of cardboard to 6 millimeters of the wood.

The motor mobile boxes gave me much troubles. My intenction to made them in a reduced space clashed with the occuped space of motor and pipes.

That forced me to enlarge the structure width and height by one centimeter.

And I resolved the motor boxes space trouble moving the lateral walls inside the piece.

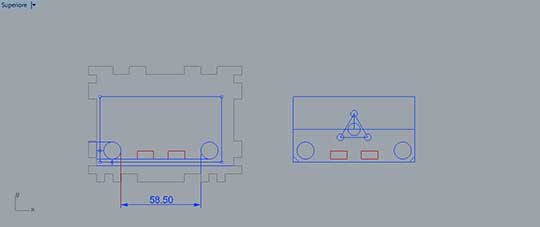

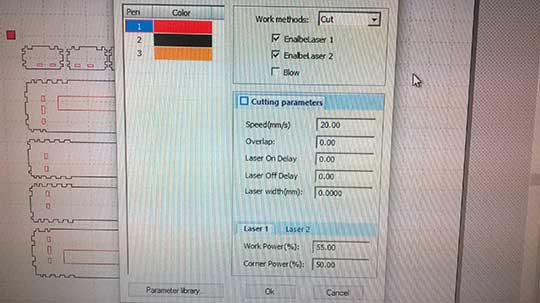

I made the the cut with those parameters:

Speed: 20 mm/s

Work power: 55%

Corner power: 50%

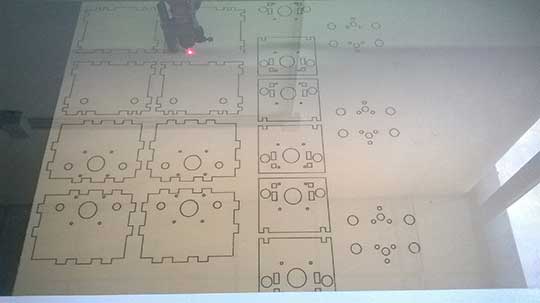

And I made two cutting process to obtain a clean result.

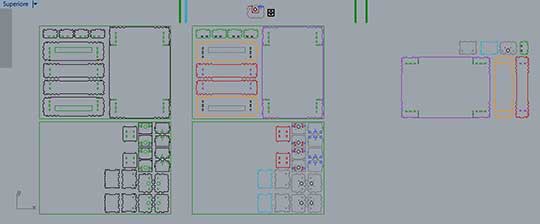

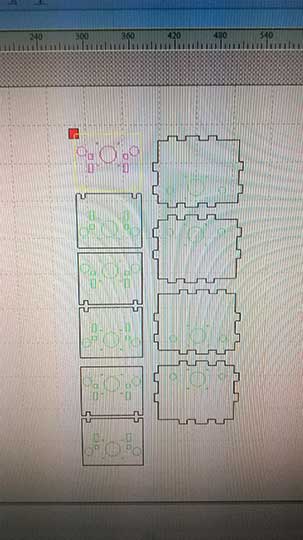

How you can see I used different colors and priority for the cutting. Respectively: Holes first and boards after.

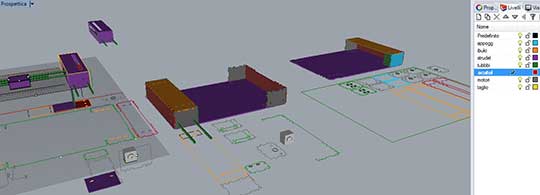

But I recognized another problem. I used the structure of a motor box to made the tool box, however I haven't considered that I have to turn it upside down.

And the height of the machine wasn't sufficent enough for that piece.

I made a new middle structure, and in the laser cutter program I used different color to make tests, turning off the other parts avoiding wasting of material.

Finally The structure was ready, and we only need to assembly it!

This machine was thinked to be a pizza cutter too. However the tool construction required a lot of time, so we used it as a pantograph. But it could make both just changing the tool and the program parameters.

Copyleft © Alessandro Patrizi 2016