WEEK 7

COMPUTER-CONTROLLED MACHINING

Assignment

- make something big

Learning outcomes

- Document the process of design and production to demonstrate correct workflows and identify areas for improvement if needed

Assignement's files

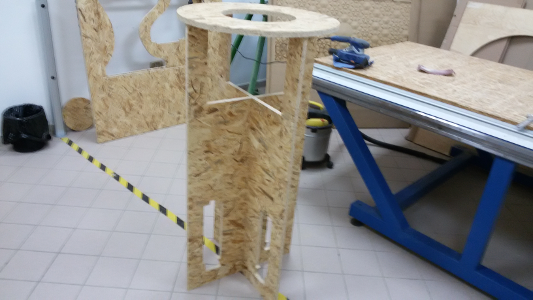

This week's assignment require to make something big using a CNC Milling Machine and a single OSB (Oriented Strand Board) 2100x1100x18 mm in size

I decided to build a new version of one of my project's structure which it's tall enought to be used in stand

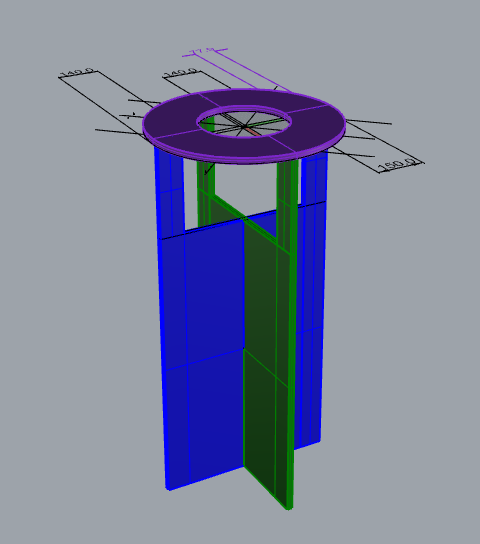

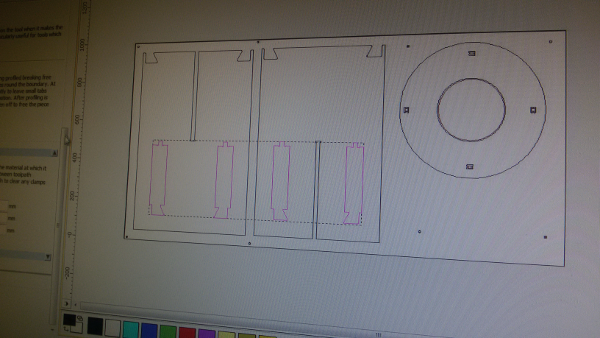

First I made a 3D model

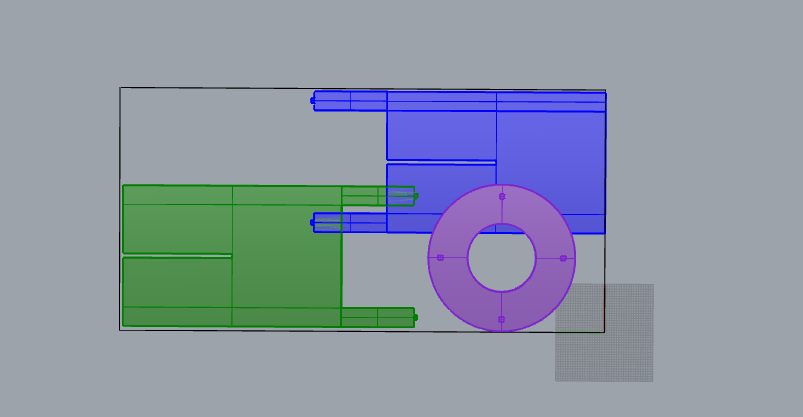

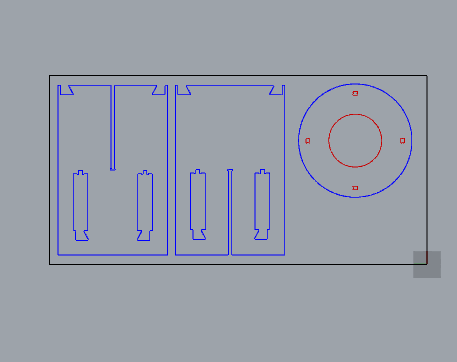

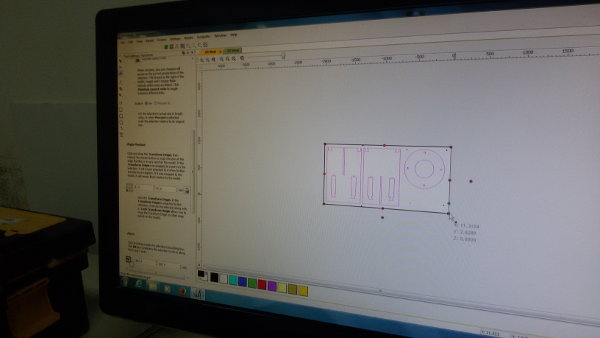

Then I placed every single piece on a single place

Due to board resctriction I had to find a solution, do I cutted some piece in order to use the available board

Then I added some engrave point to fix the board on CNC machine

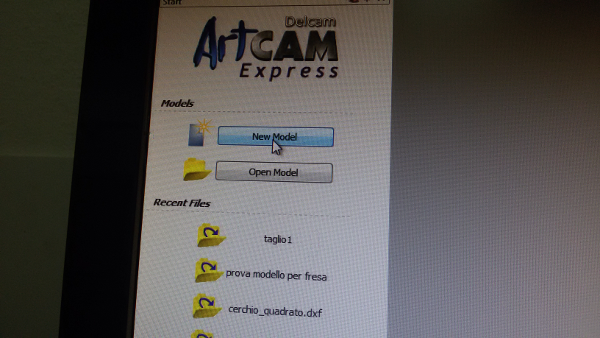

Once exported files in DFX -2004 -lines format ha had to use Art Cam software to set the CNC, so I started ArtCam software and clicked on "new model"

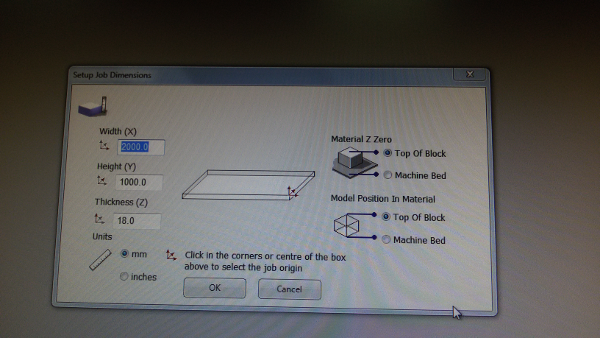

Then set the board width, height and thickness. The Z zero to top of block

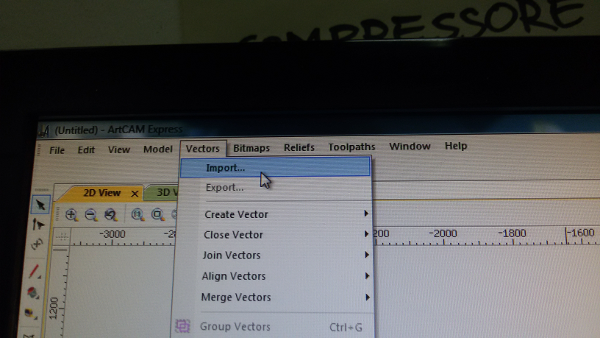

click on Vectors -> import

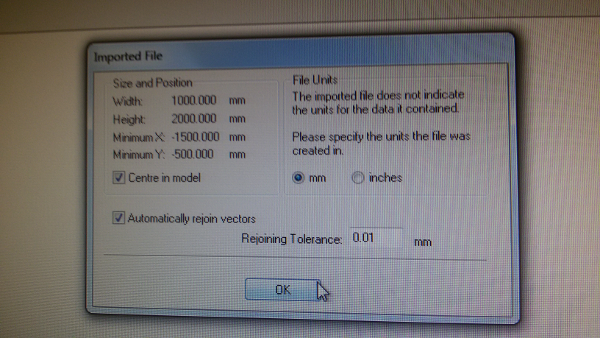

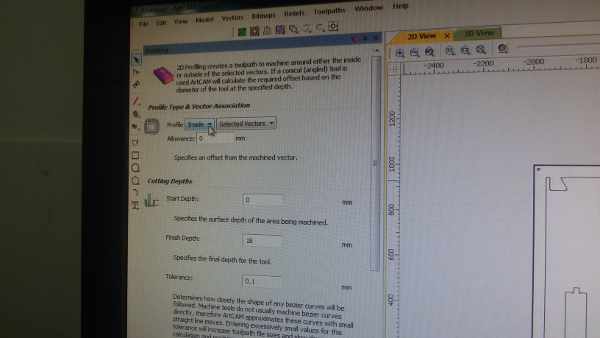

set the tollerance

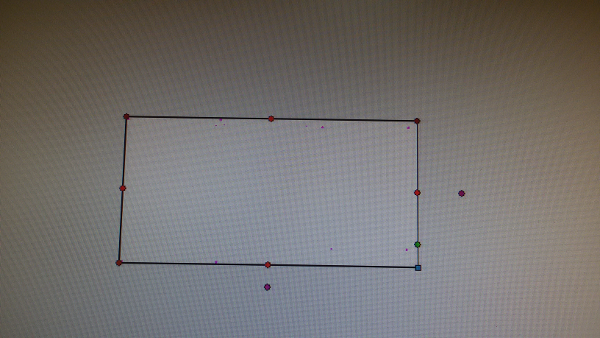

place the vector of engraving points in order to screw the board on surface

select the engraving points

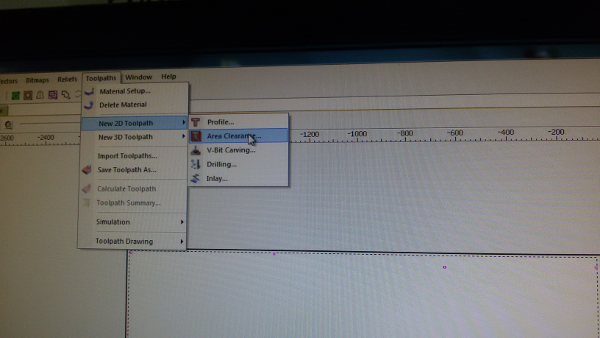

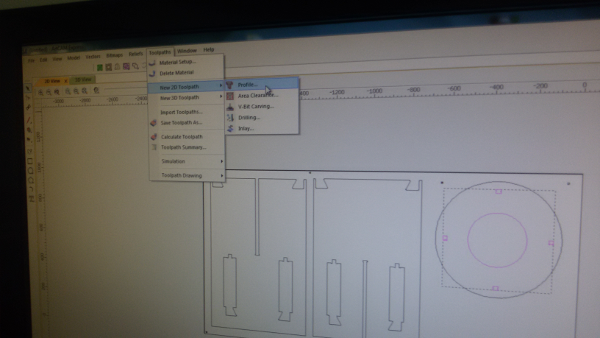

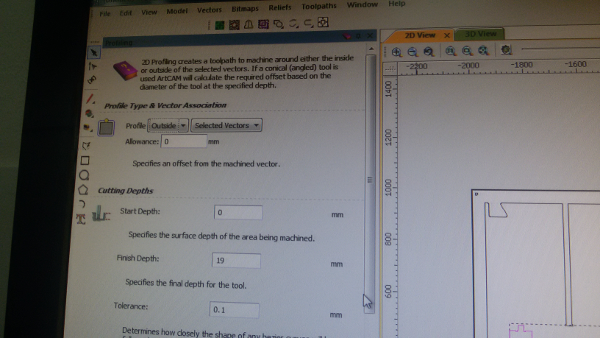

Make a toolpath, select toolpaths -> new 2D toolpath -> profile

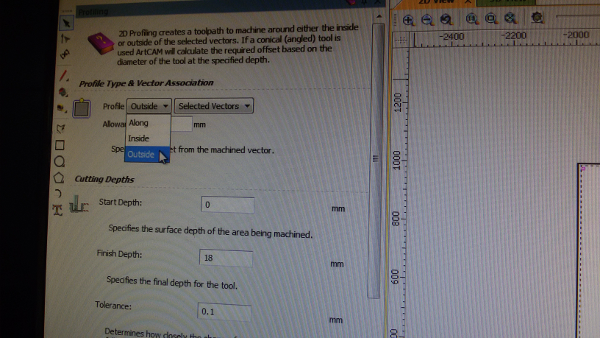

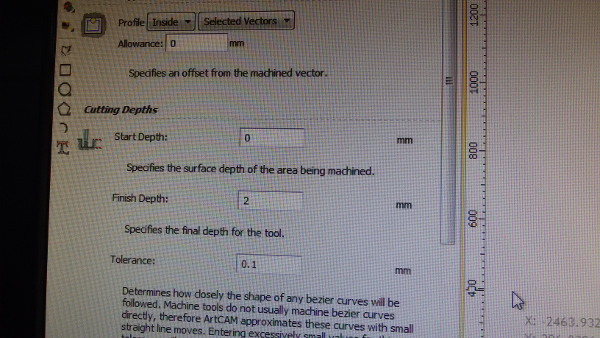

selecti nside

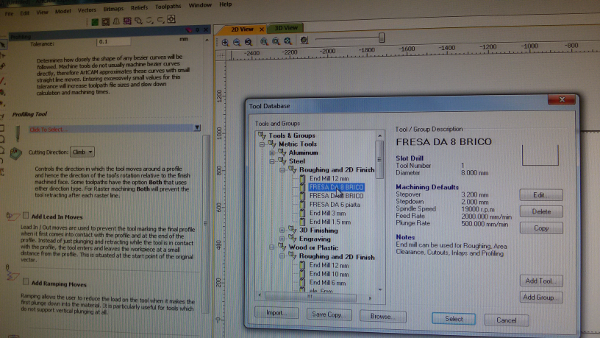

select the tool , in my case 8mm diameter

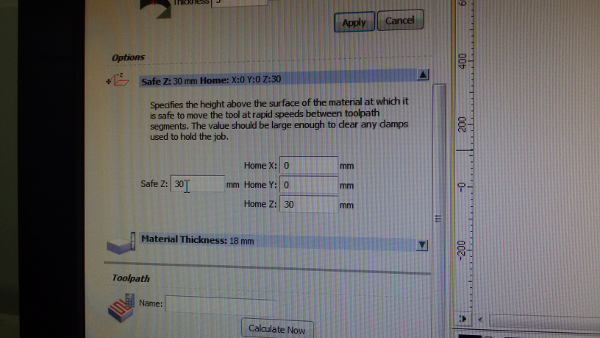

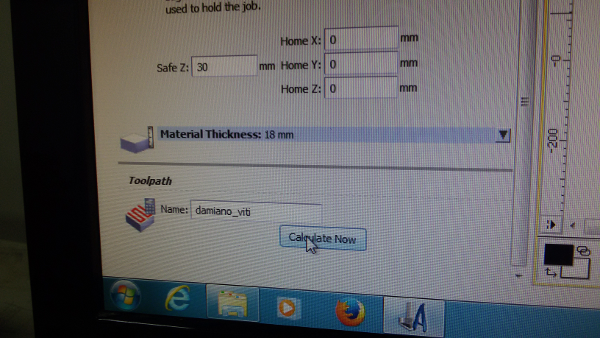

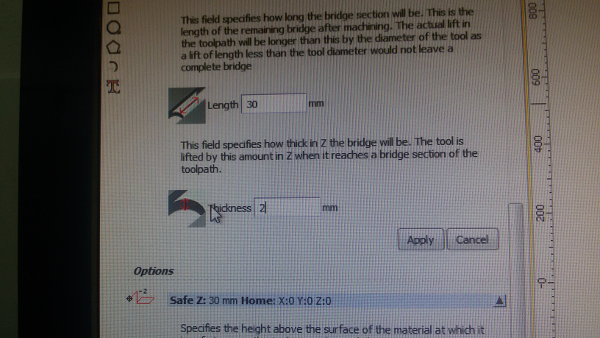

select the safe Z, moving from one point to another the tool will rise of 30mm in order to avoid damages

click on calculate

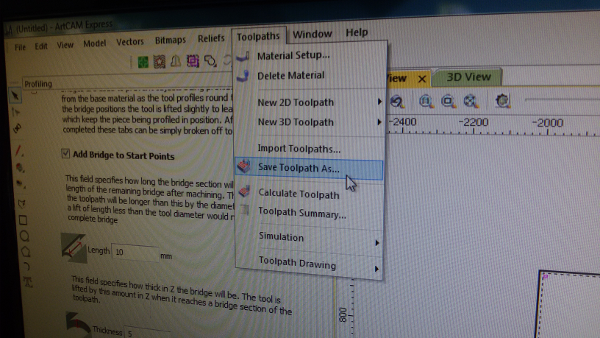

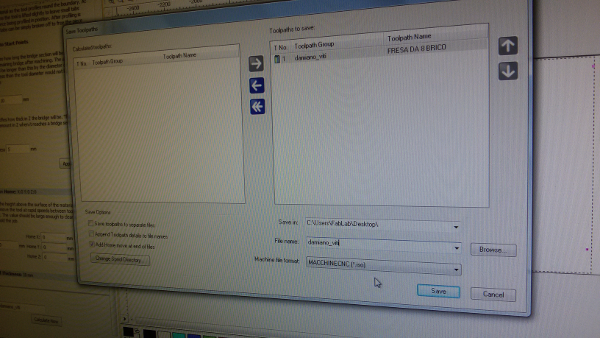

and save!

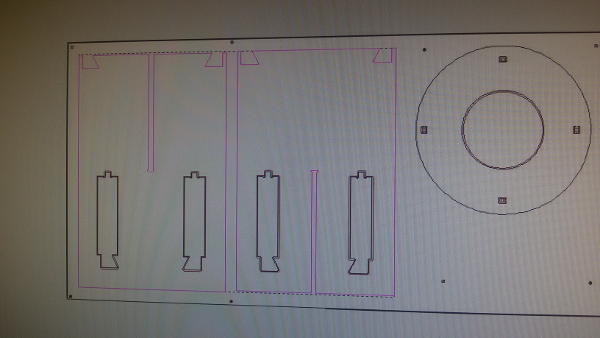

now is time for cut file , over the engraving file

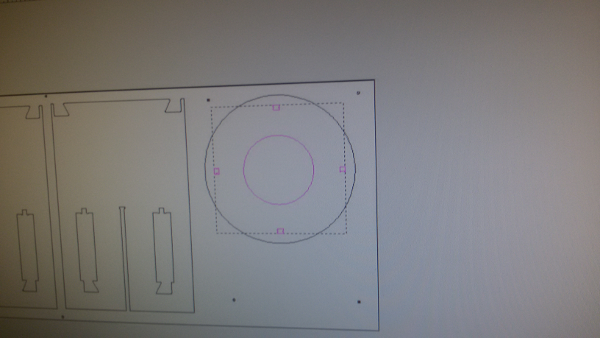

select vector for inside cut

select inside

now is time for inside cut, due to the pieces obtained pourpouse will be used the outside trace

and the outside

setting the birdges in order to mainain fixed the cutted pieces

now it's time to play with the machine! :-)

machine settings

- MACHINE: Macchinecnc Enterprise

- END MILLING TOOL: 6 mm

- FEED RATE: 76 mm/s

- PLUNGE: 50 mm/s

- SPINDLE: 15000 rpm

- SOFTWARE: Artcam

Machine References

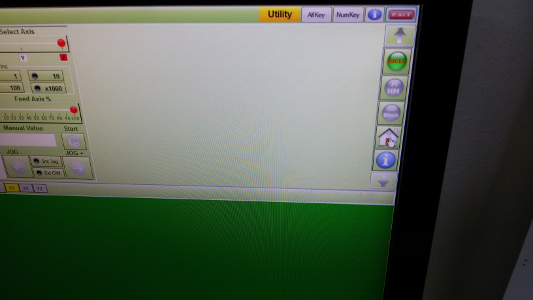

Starting ArtCam

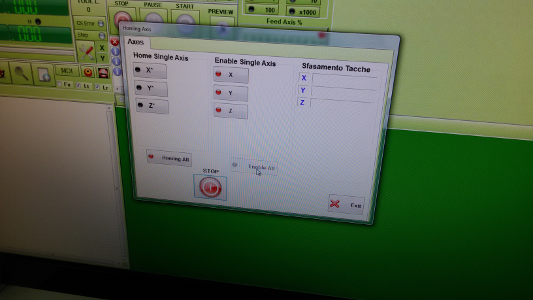

Enabling axies

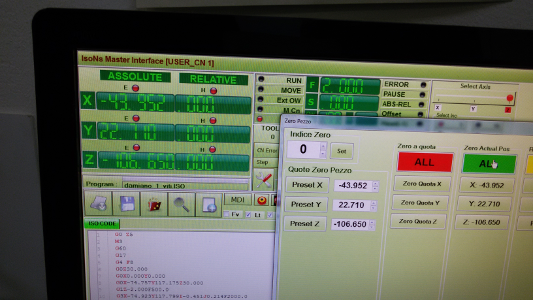

Zeroing axies to relative position

Rocks!!

almost finished

Yes! all works as I intended :-D