WEEK 5

3D PRINTING AND SCANNING

Assignment

- Test the design rules for your printer(s) (group project) Design and 3D print an object (small, few cm) that could not be made subtractively 3D scan an object (and optionally print it)

Learning outcomes

- Identify the advantages and limitations of 3D printing and scanning technology

- Apply design methods and production processes to show your understanding

Assignement's files

3D printing tech

Stereolithography

pro

- Speed

cons

- Costs

Fused-deposition molding

pro

- Costs

cons

- Speed

pro

- Big dimensions of printed objects

- Speed

cons

- Costs

pro

- Multicolor

cons

- Costs

Scanning tech

pro

- Con look for internal structure of complex industrial part

cons

- Suitable for industrial application

pro

- 360 degree laser scanner

- cost

cons

pro

- Precision

cons

- cost

pro

- Open source

cons

- Picture precision

This week’s assignment was to print an object which connot be made subtractively and then 3D scan on object

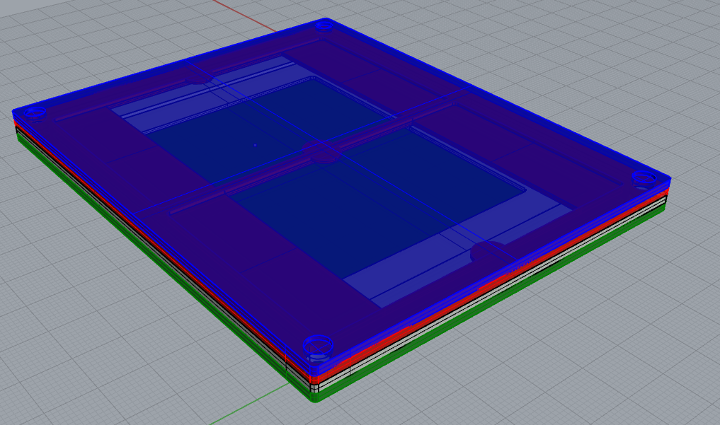

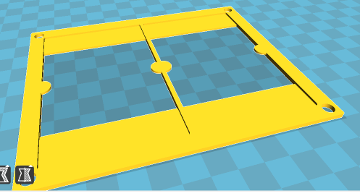

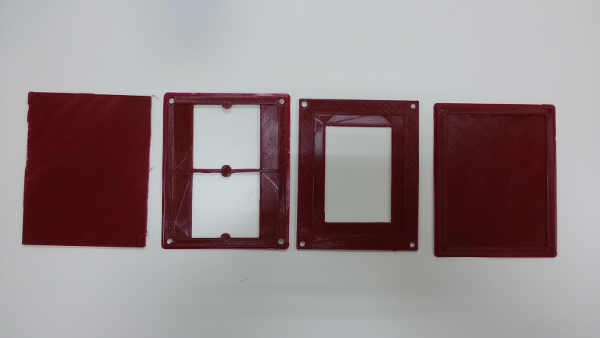

For 3D printing assignement I made a modular wallet. Each layer made to hold a kind of object kept toghether by little magnets on edges. In this case there's only two kind of layers other than the top and bottom layer whose are used to keep all the layer together

Why this project cannot be made by a milling machine

This object con only be made by additive tecnique because some parts cannot be made by 3 axis milling machine

The modular wallet credit card module is equipped with parts specifically created to hold through a joint credit cards

These parts can be made with a milling machines only milling it on both sides milling one surface at time. It can be risky so is better to use addictive tecniques

In our lab thre's a Formlab Stereolithography (SLA) printer which has a higer detail level for this kind of job, so I used the Wasp Delta 40x70 witha resolution of 100 micron

THESE ARE THE PRINT CARATHERISTICS:

- Cylindrical Print Area: 600mm diametr x 1000mm height

- Layer resolution: 100 micron

- Nozzle Diameter: 0.4 mm (0.7 mm, 0.9 mm)

- Filaments used: 1.75 mm (PLA, ABS, Flex, HIPS, PETG)

- Printing maximum speed: 200 mm/s

- Travel speed: 200 mm/s

- CHANGEABLE EXTRUDER

- With extruder for fluid-dense materials you can use clay, porcelain, etc…

- SOFTWARE

- Operating Systems: WIndows, Mac, Linux

- Software slicing: Cura – SLic3r – Simplify 3d

- File type: .stl, .obj, .gcode,

- INTERFACE

- SD Card – LCD Screen

- PHYSICAL DIMENSIONS

- Dimensions: 118 x 104 x 254 cm

- Machine weight: 100 kg

- Dimensions for shipping with wood packaging: 267x122x127 cm, weight 250kg

- SUPPLY

- Input: 220/240V 50/60 Hz

- Power Consumption: Max 750W

- TEMPERATURE

- Use: 20-30 C°

- Warehouse: 0-30 C°

- Nozzle: max 260 C°

- Hot Pad: max 100 C°

- MECHANICS

- Frame and cover: Aluminium, polycarbonate and wood

- Printing bed: Steel

- Movements: industrial guides on alluminium slides

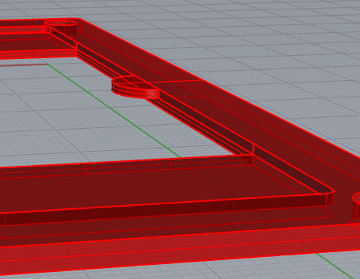

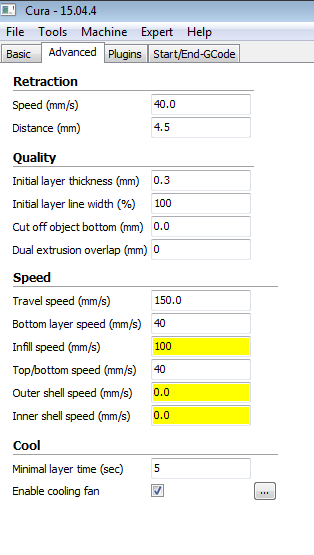

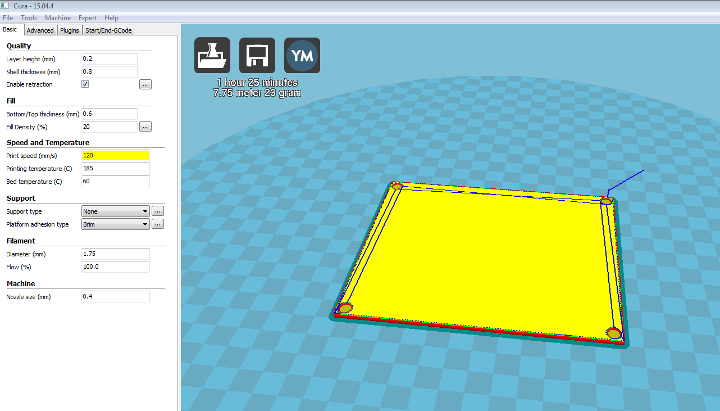

From Rhino file I used Cura software from Ultimaker to create the GCODE

THESE ARE THE PRINT SETTINGS:

Delta printer at works and resulted objects

Problem with scanning

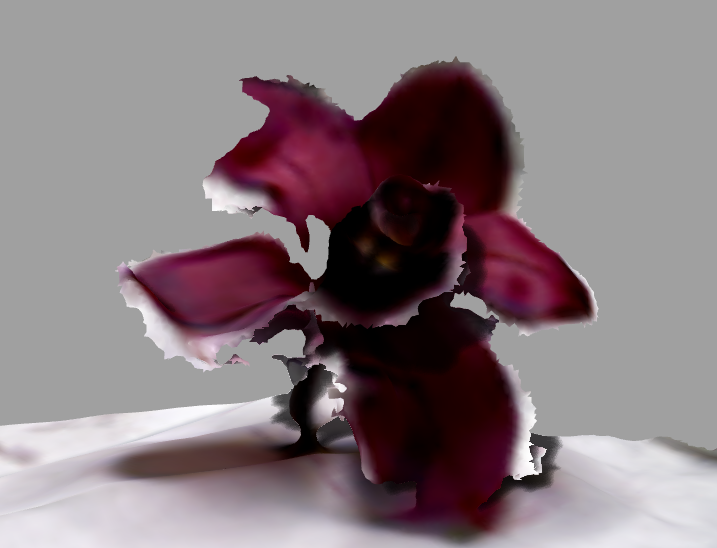

For scanning assignement I choose to scan an orchid because i want to test the scanner n a very hard job. It was really challenging and the result wasn't really good. In this case to solve the problems I should use a better illumination, an arm made to hold the scanner and a rotative surface for instance like Rubicon

I used a Sense scanner