COMPOSITES

WEEK 14

Task:

Design and make a 3D mold and produce a fiber composite part in it

Materials

- Corrugated cardbord

- Epoxy resin (POX BAK 1206)

- Fiber :Lino

- Film or plastic packaging

Software

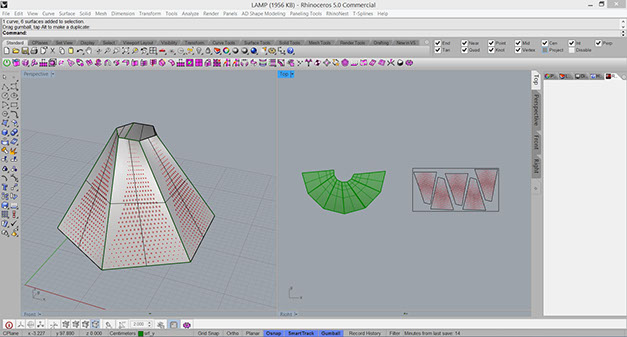

- Rhinoceros

- Coreldraw

DESIGN PROCESS

For the assignment of this week I design a lamp, for when the lights turn on you can appreciate the texture of the resin and the fiber cross the light between the fiber.

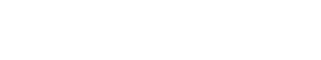

Process of the design lamp was by waffle modeling in rhinoceros for make the structure, find the steps in this assignment

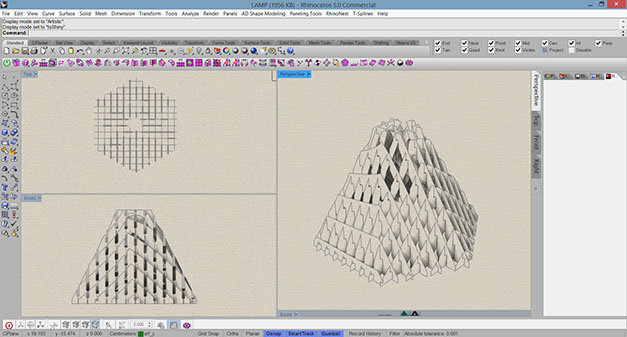

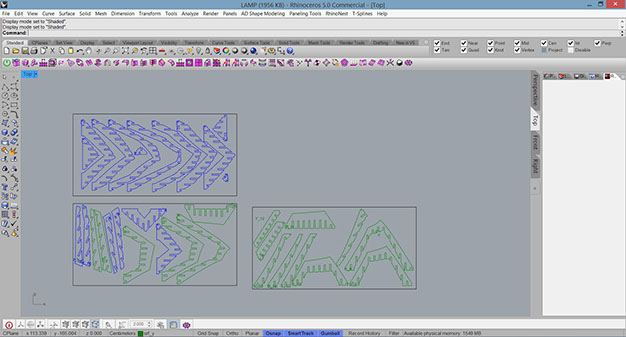

Prepare the parts of corrugated cardboard of the lamp to be cut by laser and then be assembled.

Assembly of the pieces. It took me longer than thought-out because the join were bigger than .4mm

The next step is make a cover with film and the cover it with the fiber. Put a surface of vaseline to not adhere to the fiber

Before placing the fiber, unroll the faces of the lamp for cut by laser each part of the faces.

Command in rhinoceros: "unrollsrf" (follow this tutorial)

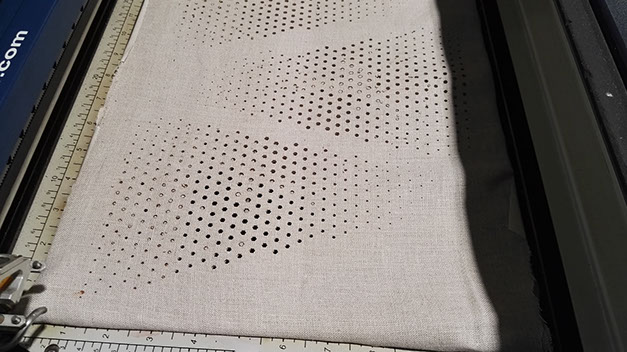

The laser cutting process following this week

Make sure to not get burn the fiber.

Start to cover the lamp with the fiber

Cover totally with the fiber

The compose of the resin is 1 5

.jpg?crc=466023220)

Make a mix of pox bak 1/ 5

36 hours later

With the lights on

Learning outcomes

- Recognise the benefits and limitations of 3 axis machining

- Demostate workflows used in mould design and construction

- Select and apply suitable materials and processes to create a composite part.

Have you

- Shown how you made your mould and created the composite

- Described problems and how you fixed them

- Included your design files and "hero shot" photos of the mould and the final part

Download files of week 14

Copyright © Jorge Huang Li - FAB ACADEMY 2016