MOLDING AND CASTING

WEEK 12

Task:

Design a 3D mold, machine it, and cast parts from it

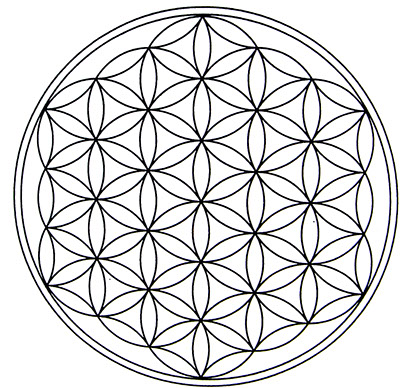

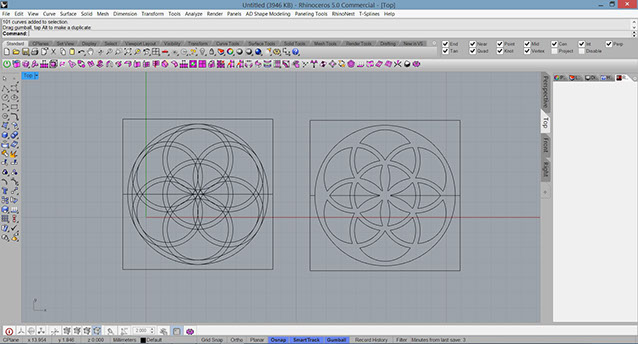

3D MOLD

Materials

- Wax 80 % and %20 plastic

- Cement

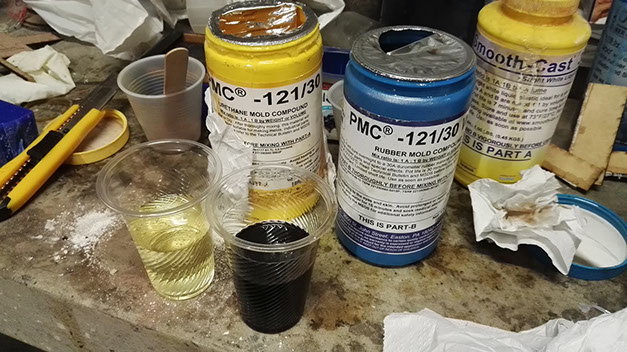

- PMC 121/30

Machine: Roland modela

Software:

- Fab Modules

- Rhinoceros

3D mold + cast

First steps

First steps: Make 3D model a measure the correct distance

Make a mold of the 3D model and export it in .stl

Milling

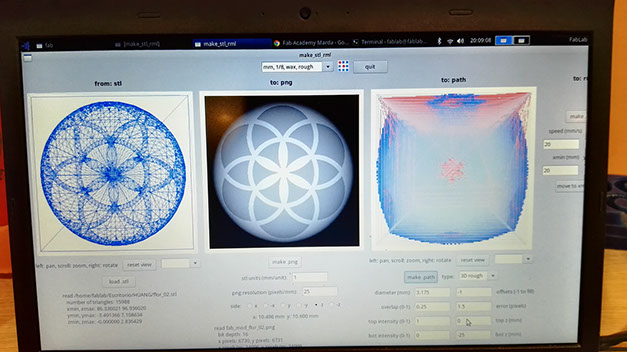

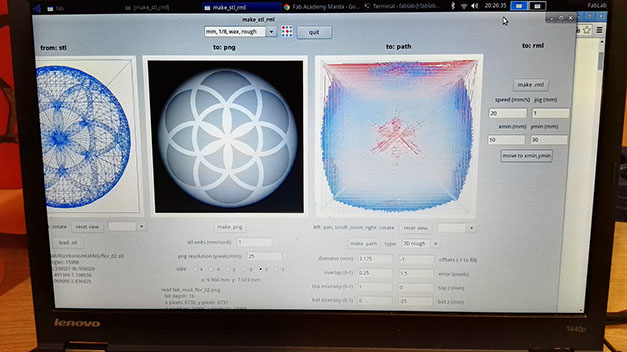

Open terminal in ubuntu

- Type sudo fab

- upload the .stl model

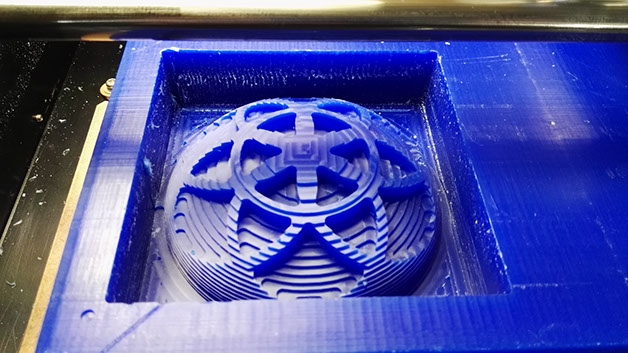

- Put the wax piece in the modela

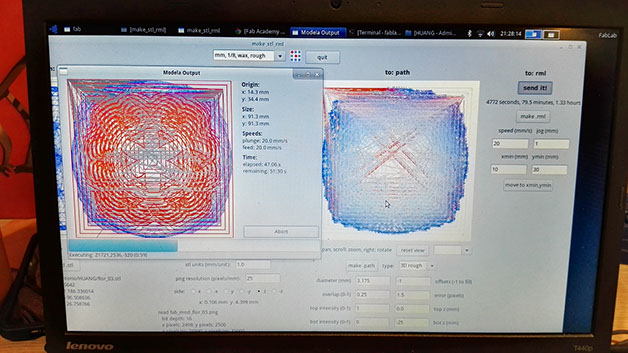

Select milling cutter size, material and process: "mm, 1/8, wax, rough",

The milling take more than 2 hours.

Casting

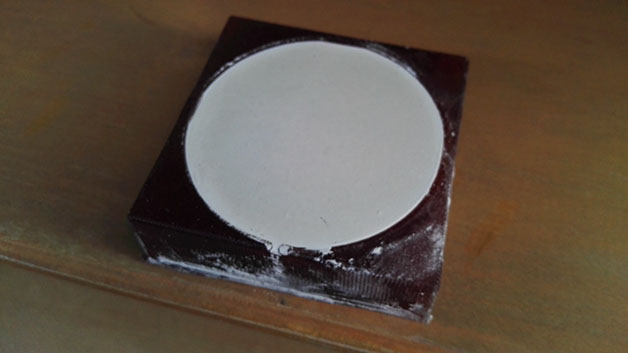

Make a mix equal of PMC 121/30

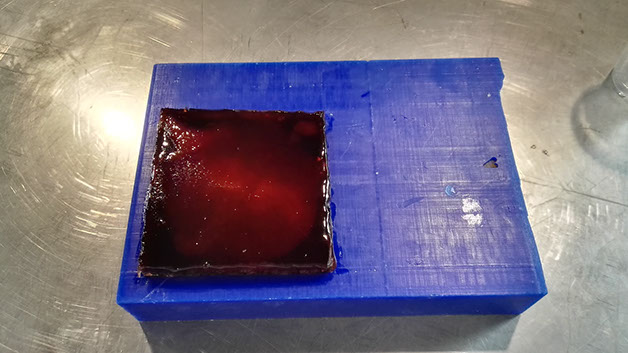

Put the mix in the wax 3d models

Wait 24 hours for dry

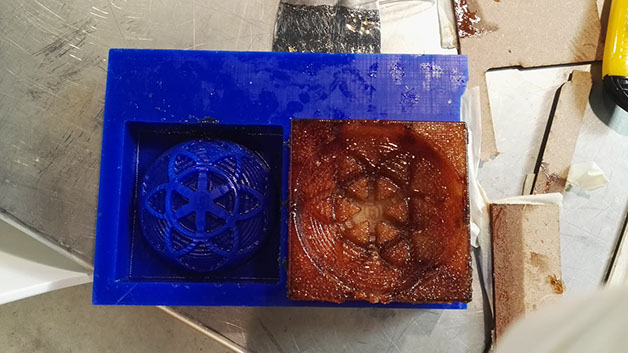

Remove the support

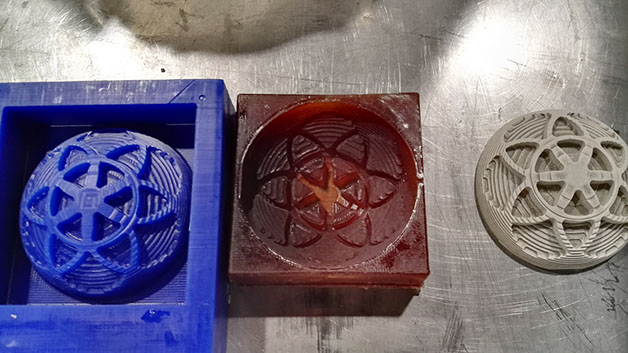

Look great but not

The mix was not consistent

So I need to make it again

Casting part two

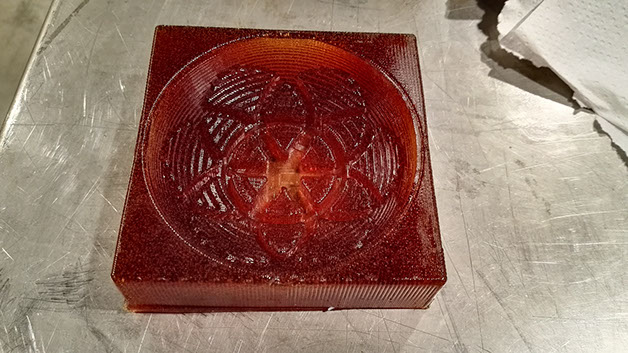

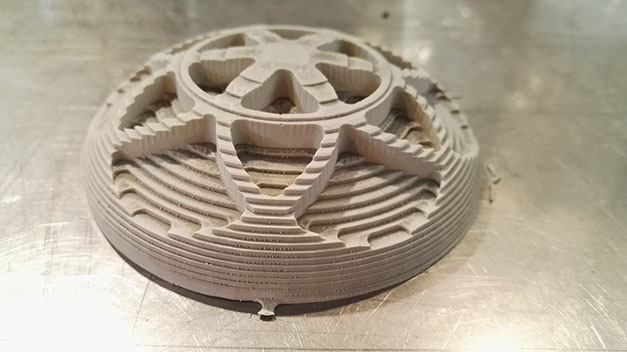

This time look great with the same process

Comparative of the models

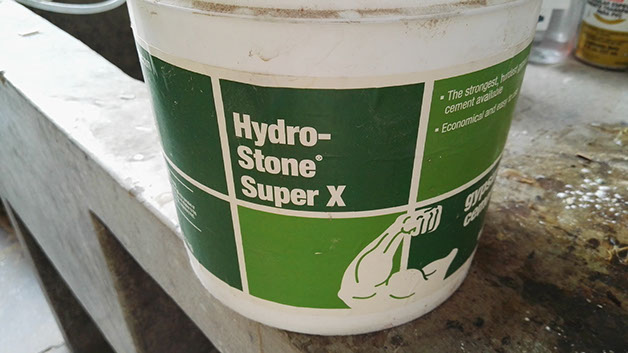

Hydro-sone Super X is instant cement

The mix consist 5 of cement and 1 of water

I let it dry and less than an hour is ready

outcomes

Learning outcomes:

- Design appropriate objects within the limitations of 3 axis machining

- Demonstrate workflows used in mould design, construction and casting

Have you:

- Explained how you made your files for machining

- Shown how you made your mould and cast the parts

- Been surprised today

- Described problems and how you fixed them

- Included your design files and "hero shot" photos of the mould and the final object

Download files

Copyright © Jorge Huang Li - FAB ACADEMY 2016