COMPUTER-CONTROLLED MACHINING

WEEK 07

Task:

- Make something big

Machine:

- ShopBot

Software:

- Rhinoceros / T-Splines / Script

- Vcarve

- ShotBot control software

Materials:

- MDF: 9 mm

- clipboard

- Milling cutter:

Make something big

Background

Five years ago I participated as an architecture student in a design competition " African cultural heritage in Brazil and Peru", aimed at student and professionals. Organized by the Brazilian Embassy. This contest focuses on fostering creativity focusing on the cultural exchange that has had throughout history of Peru and Africa. under this concept design works that can be a furniture. At the time I made a furniture of corrugated cardboard, assembly and manually cuts.

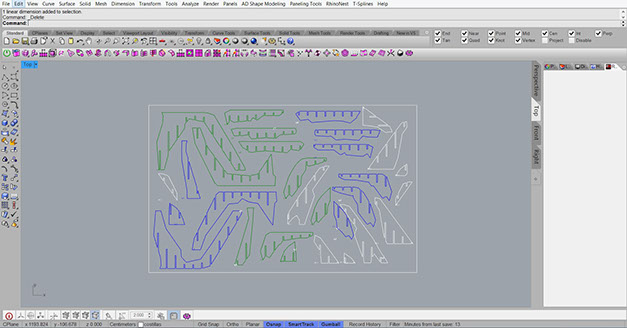

Rhinoceros / T-Splines / scripts

Waffle System

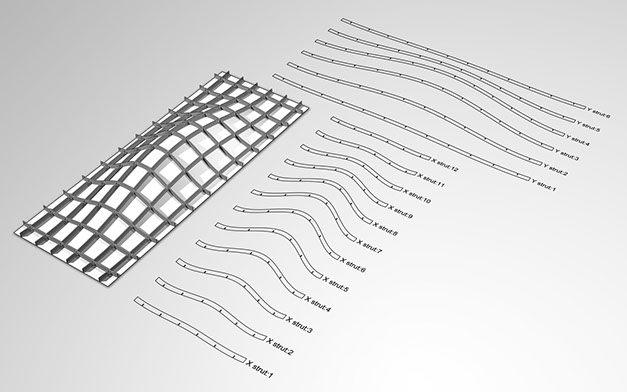

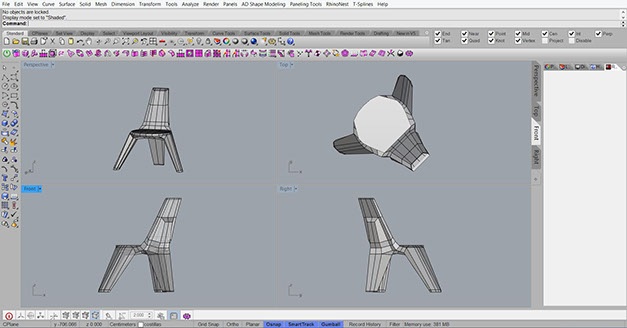

For this week the assignment is "make something big" so I design a chair of tree legs and seat back support assembly connected with a piece printed in 3D.

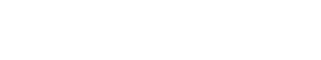

Waffle structural system is a method for intersect structure between two surfaces making ribs on x- and y-axis for prepare the 3D model for the CNC mill or laser cutter in Rhinoceros there are different methods: manually by the command "contour", in grasshopper by a definition(Waffle_Structural_System.gh) and with a plugin Rhinonest

via Lift Architects

The waffle system was made following this tutorial by Chidostudio(spanish)

First step: Modeling a chair

In this case the chair was modeled in rhinoceros with the plugin T-Spline. First of all the chair started by a box and then it was edited to reach an octagon, after the edges are extruded for define the legs and the seat back support. Until adequate measures.

-

Short cuts

- A: select vertex

- S: select edged

- D: select faces

- F: select objects

- Tab: toggle smooth

- command "tsInsertEdgeSimple": define the smoooth edges

Second step: waffle system

After modeled the chair, following the tutorial by Chidostudio

-

Steps

- "Contour" command to make the gaps between ribs in x-axis and y-axis.

- "Planarsrf" command: fill and make a surface

- Load script » cut my own ribs » select ribs by axis » put the dimension of the material

- Load script » select ribs by axis for enumerate each one

Final result

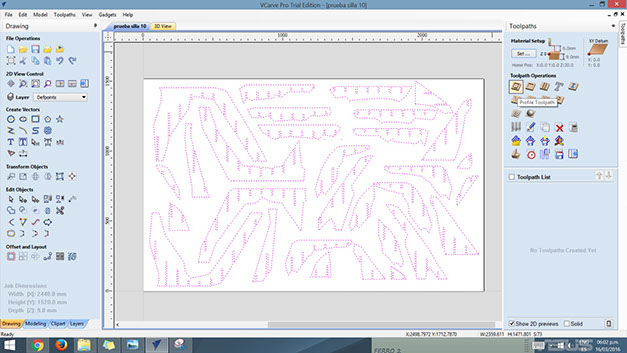

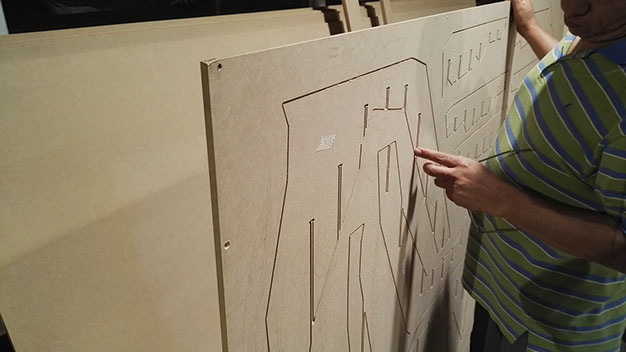

Place each piece, the size according to the table (in my case I used MDF of 2.44m x 1.52m x 9mm) and then export it in .obj format

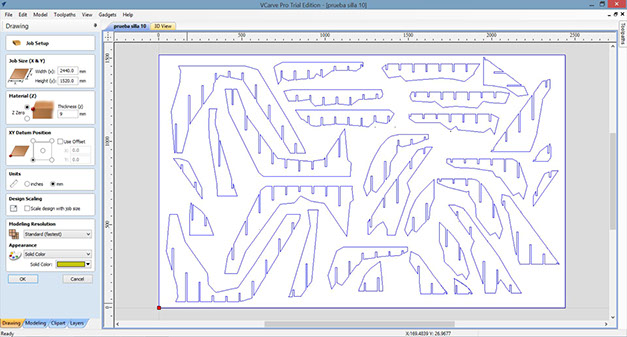

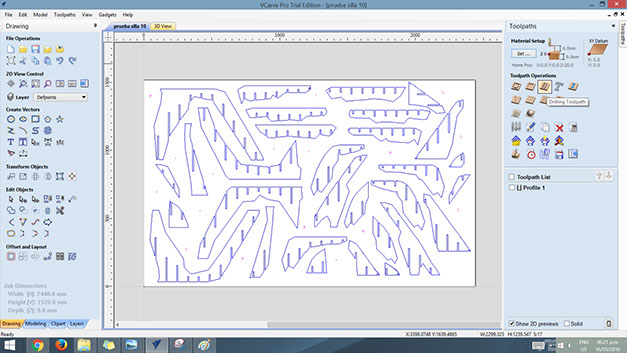

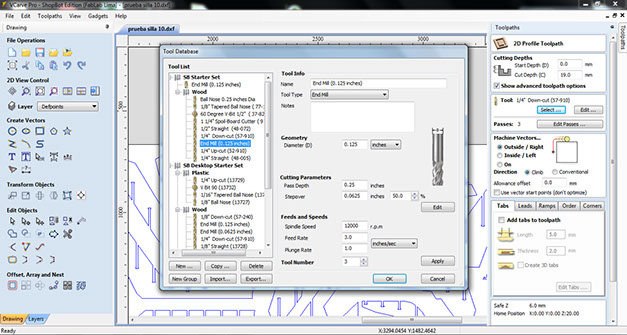

Vcarve

Vcarve is intuitive software solution for prepare 2D and 3D design to CNC routing.

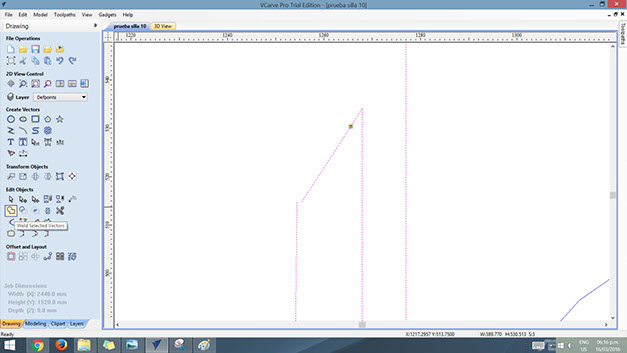

Open Vcarve and open the file exported. Choose the size wooden board, material trickness, units and the most important uncheck useoffset

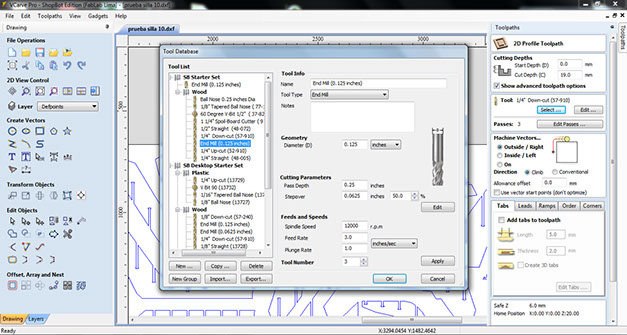

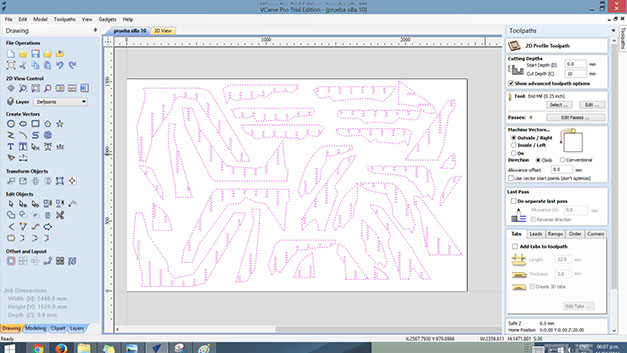

Toolpaths / 2D profile toolpath / choose the type of mill

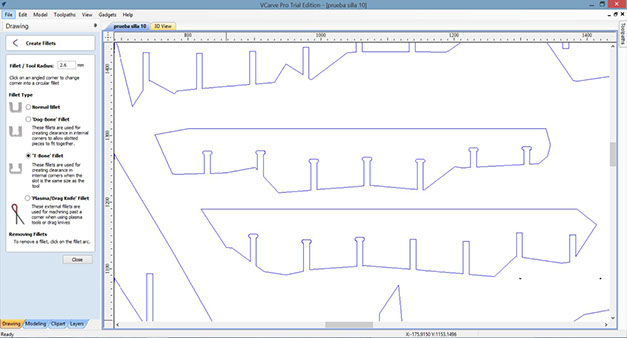

Edit objects/ create fillets / t-bone

The cutter millet can't make 90 degree pass

Transform objects / weld selected vectors

Weld open vertex of each object

Cutting Depths : 1mm more of the board trickness

Machine vector : in my case outside / Right

Select pieces

Cutting Depths : 1mm more than the board trickness

Machine vector : in my case outside / Right

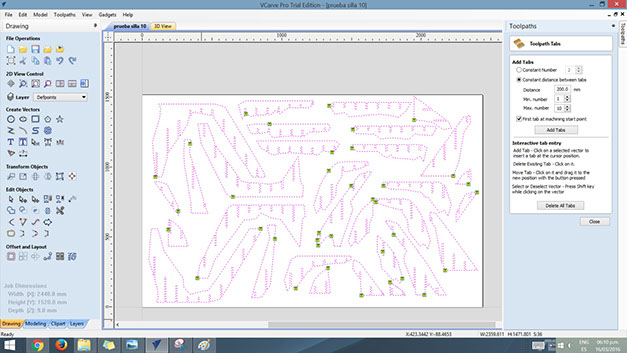

Check in add tab to toolpath prevent parts from moving to pass the milling cutter/ save profile

drilling toolpath: made safety the wood board

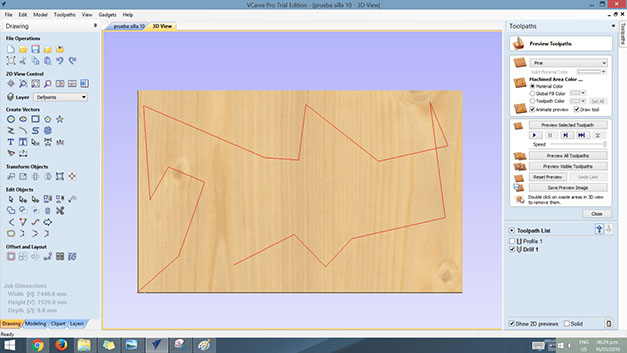

Preview toolpaths, show path/ save profile

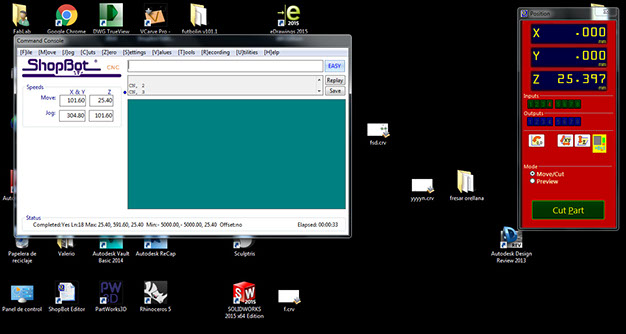

Shopbot software

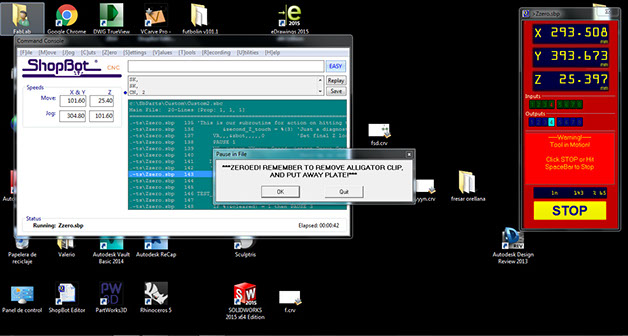

The process of the shobot soft has few step: calibrate XY, Calibrate Z and Cut part

First steps calibrate xy axis and z axis with the aligator cups

- Open shotbot software

- Calibrate yx axis and then calibrate the z axis with the aligator cup

- Open drill profile

- screw manually the board

Second step: send file to be cut

- Open profile toolpath

- Calibrate xy and z agian

- Cut Part

- Start

- Recall Last

- When start router the computer start freze

PUSH green button to start

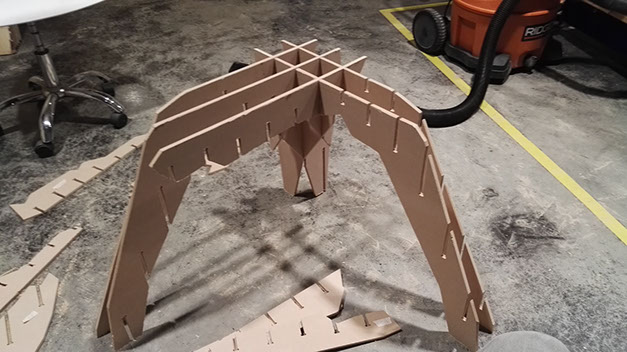

After 1 hour and 30 minutes the each part are ready to be assembly

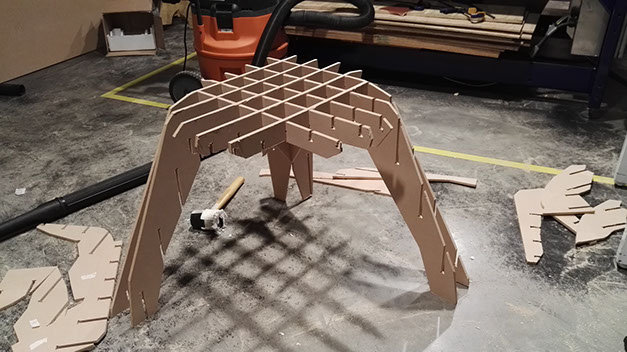

Assembly

- The joins of each parts are to large to be assembly manually so I need a hammer for union the pieces

- The assembly of the chair took me over more than 3 hours

Heroshoot

Heroshoot

Problems / fix

The milling cutter not pass the trickness of the MDF of 9mm

Here are tow solutions for start to assembling the chair

- Use drill and drill all the parts again manually: I think it was easy, but not drill all the pieces again took me over more time than shotbot drill the MDF

- Make it again and change the cutting depth to 10.5mm or 11mm

Some problems with the joins, I used to much forced with the hammer and I broke the some parts of the chair but it still strong and can carry my wight

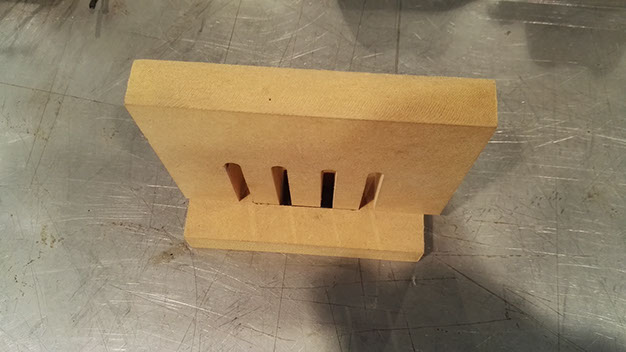

Some joins tested before to start send my chair files

Learning outcomes

- Document the process of design and production to demonstrate correct workflows and identify ares for improvement if needed.

Have you:

- Explained how you made your files for machining

- Shown how you made something BIG (setting up the machine, testing joints etc)

- Described problems and how you fixed them

- Included your design files and "hero shot" photos of final object

Download files

Copyright © Jorge Huang Li - FAB ACADEMY 2016