Overview

For this week's assignment, It was required to design and implement something big on a CNC machine.

For this task, I designed and implemented a small table.

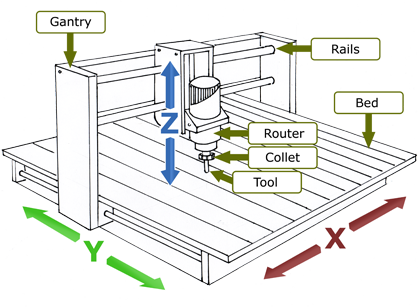

What is a CNC?

The term “CNC” is a generic term which can be used to describe many types of device, this would include plotters, vinyl cutters, 3D printers, milling machines and others. CNC stands for Computer Numerically Controlled and basically means that the physical movements of the machine are controlled by instructions, such as co-ordinate positions that are generated using a computer.

The term “CNC Machine” is typically used to refer to a device which uses a rotating cutting tool which moves in 3 or more axes (X, Y and Z) to cut-out or carve parts in different types of materials. The information on these pages will focus on what are typically referred to as “CNC Routers” although it would be applicable to most CNC milling and engraving machines too.

1st Step: coming up with ideas and design.

For this week's assignment, I decided to look more around and implement something applicable and useful to use in my work or domestic space.

A funny story happened while I was brainstorming for ideas. I was having a chat with the school psychiatrist and we were laughing about having a sharing session, and she told me "Unfortunately, I don't have a chaise long, so you can stay and talk"; so I replied "Well, let's do it! :D " . And this is how I got my first idea for this week's task.

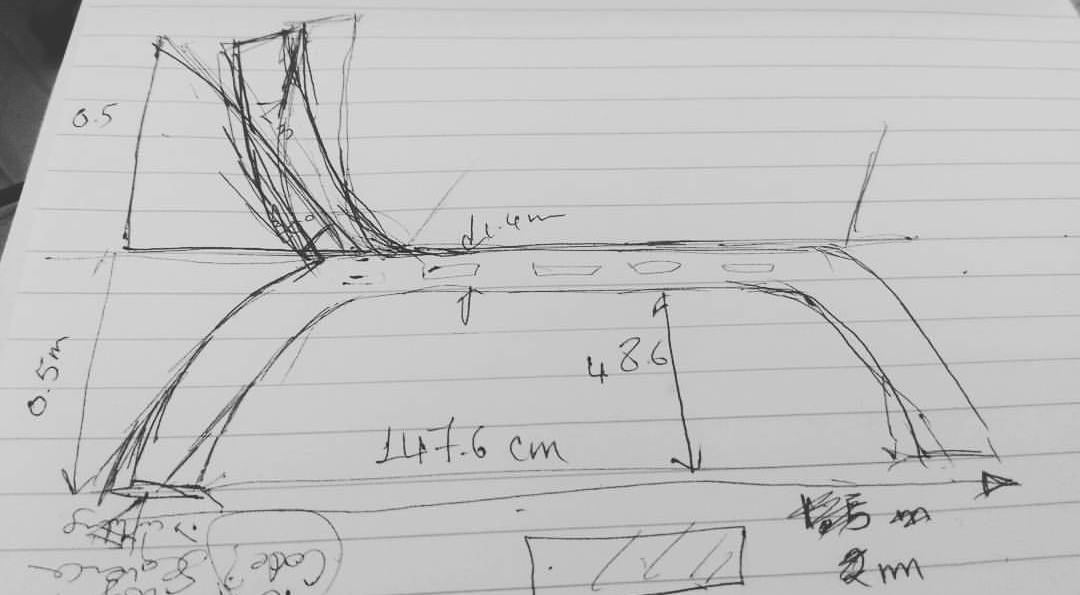

I sketched the chaise long along with dimensions as shown in picture. It's a simple structure from both sides, connected with sheets inhereted as press-fit.

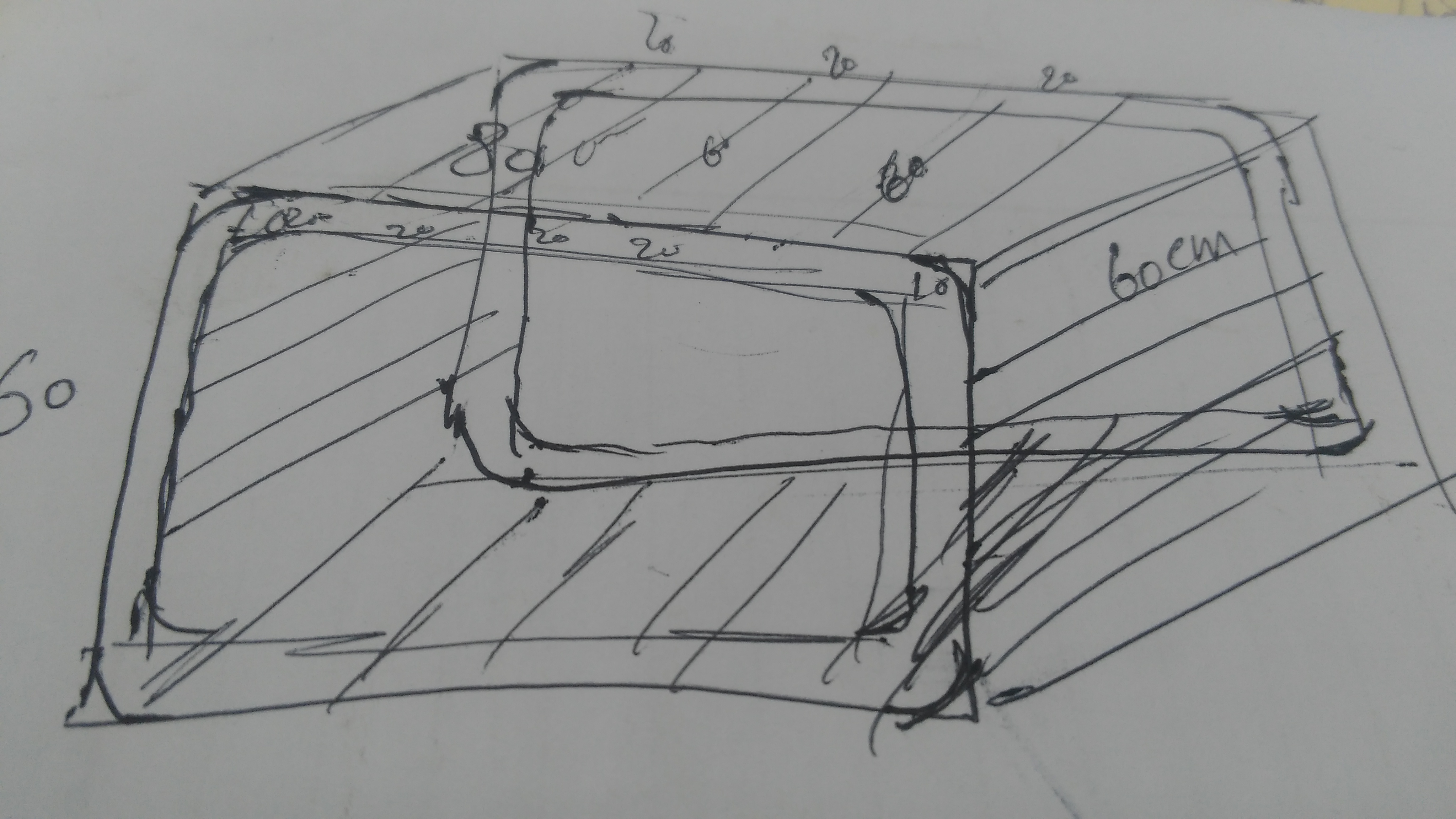

My second idea was the table, and this what I went for at the end.

It had the same design concept as the chaise long with 2 main structures glued with press-fit sheets, shown in picture.

For CAM, I used VCarve Pro. The software is really amazing and easy to use. The full design of the table was implemented in 20 minutes.

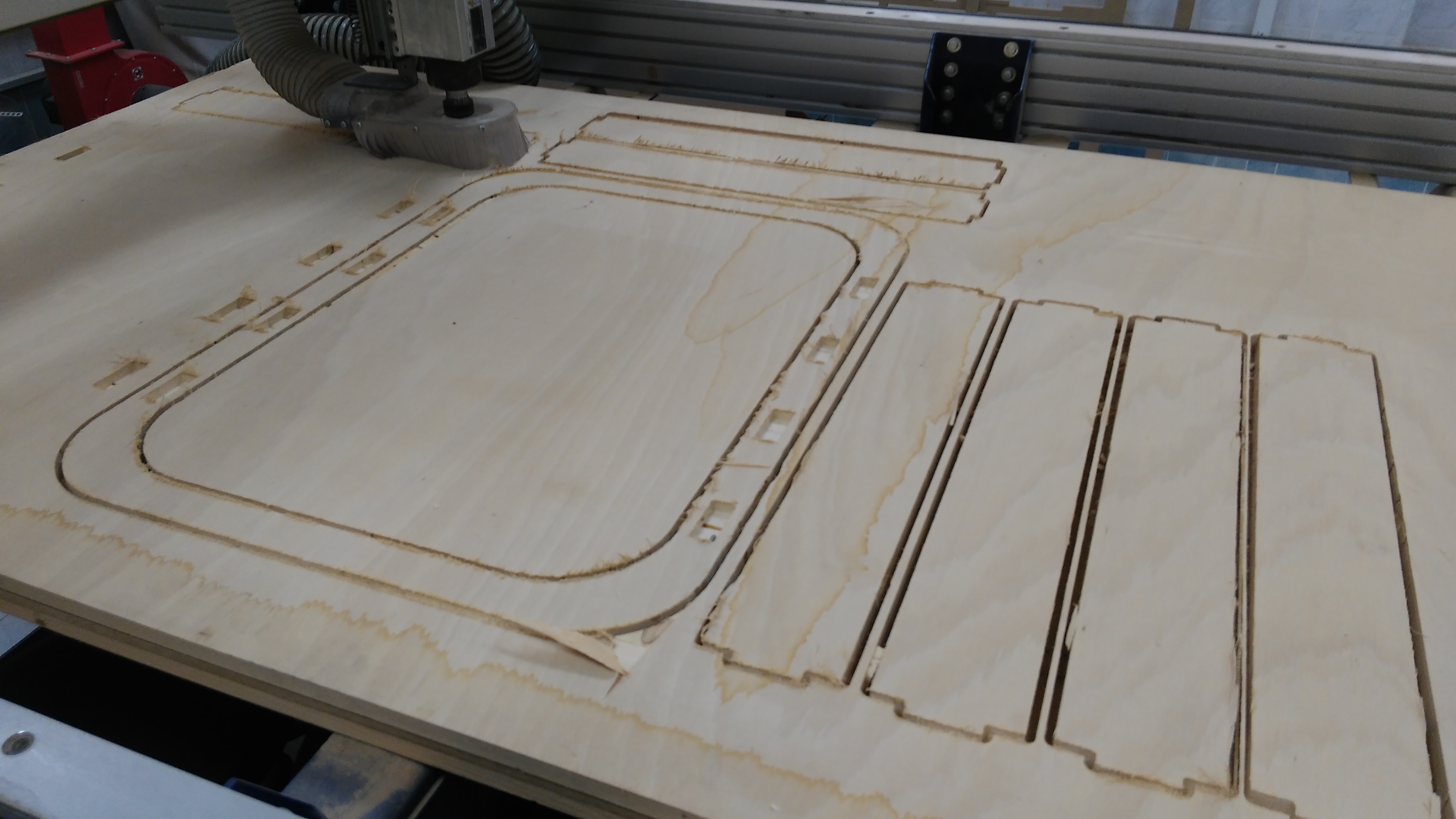

Here How it looked.

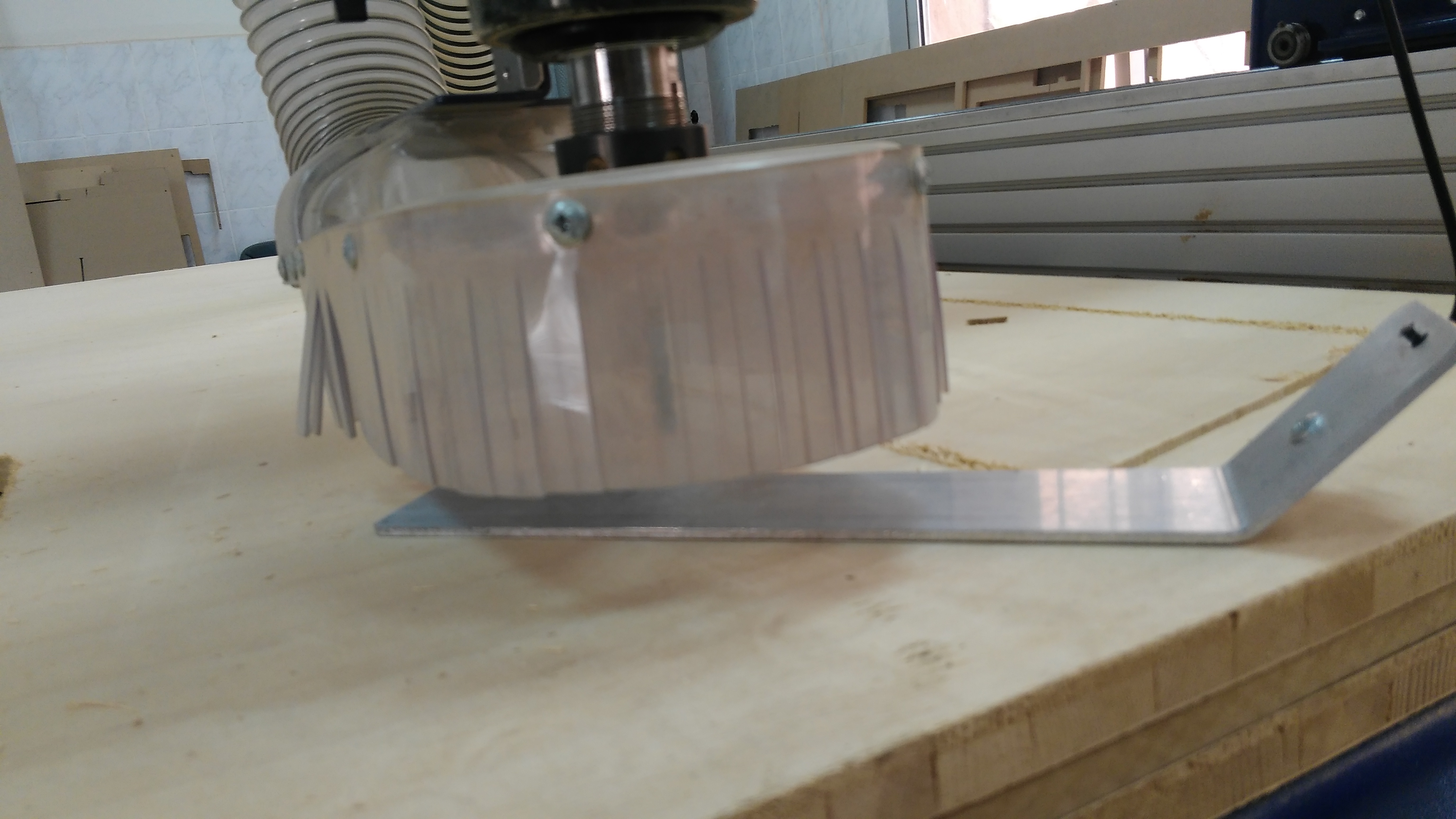

2nd Step: Setting the sheet and the machine

the next step was to set the machine and sheet. I usually use MDF wood for such deigns, but I tried for this one Plywood. You can check the different types of woods in

Then on the VCarve Pro, I saved the toolpaths files as part files for implementing the slot and for the external cut. Prepare the machine, zeroing the X,Y and Z axes. And finally cutting

And Final Product

But Let me tell you a final note, This failed miserably. The cutting needed to be in the same direction of the structure of the wood sheet to have more coherent cutting. And so, I recommend to go for MDF instead. It would fit perfectly.