Units covered:

Principles and practices, project management -> Schedule,deadlines...

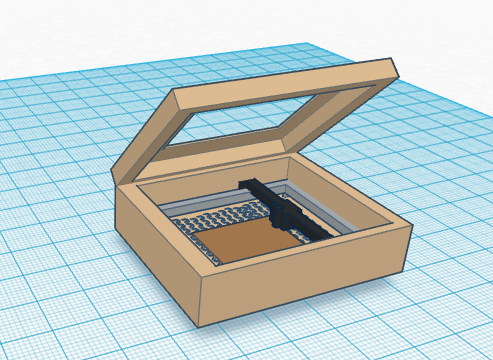

Computer-aided design -> Structural and mechanical parts

Computer-controlled cutting ->Laser cut parts

Electronics design -> designed the laser driver

Electronics production -> made the laser driver

3D scanning and printing -> 3D printed parts

Computer-controlled machining -> the casing (the initial plan was to make it on a shopbot)

Embedded programming -> modifying Marlin and using it

Mechanical design ->designed the entire machine

Machine design -> Then gave life to it!

What will it do?

My project is to build a desktop laser engraver,it would be based on the RepRap project, which means, a self replicating and modular machine. It will have a 2W and 445nm laser able to engrave most of materials and cut threw thin cardboard.

The goal is to minimise the cost but also to be able to entirely make it in a FABLAB, and I realy mean everything, the final step would be to even make the mirrors by plasma sputtering.

I also want to work on the encasing, the security and the software, so to resume, I want to :

Build a simple 2 (or 3 with auto-level?) axis machine.

Put a 2W laser on it and be able to control it.

Readapt the marlin software and the Ramps shield for a laser cutting machine.

Work on the air assitance and air exhaust

Build a casing and add sensors (and video?).

Update the laser to a 40W CO2 tube (add water cooling)

Who's done what beforehand?

Since this was the project we developed as a group during a Machine building assignment I already had some work done on the electronics, but that’s pretty much it since I changed the entire design of the machine.

On the other hand I based my project on a kit bought on Internet, I did some retro engeneering to come up with a better design and add options .

And obviously ohter people worked on the same kind of project before:

Zothar he adapted the Ramps to a cheap 40W laser bought on ebay for 800$

CNCzone here there are plenty of similar projects.

New version of MarlinA lot of people already adapted marlin to their own needs!

What materials and components will be required?/ Where will they come from?

Initialy I wanted to purchase all the materials on ebay so everyone could purchase them easily, but since ebay can be hazardous in the delivery delays I had to forgit this option (probably the cheapest).

And I found a laser kit on Amazon that actually proposed all the parts I needed (steppers,laser,bearings, cables ,gears and belts…), it also had all the structural parts which I thought would be useless for me, but I ended using there design to redo it and improve it.

I will also need some 3mm plywood and 5mm PMMA for the machine itself and a couple of 6mm plywood for the casing. In a seconde time I bought a compressor (air assistance) some joints for the casing, screws, and a OD6+ graded laser PMMA sheet. And also did some recycling:

old computer Fan for the exhaust,

old computer power supply to power the machine.

Electronics:

LM317, 2N3055, 2W resistor ( 2Ohm), 10uF capacitor, 1W variable resistor.

How much will it cost?

The kit I bought costed 260 euros with shipping and included all the steppers,belts,gears,bearings and cables and the laser!

I am going to start by listing all the parts I will need for this project, then I will detail each part.

Version 1: <400$

In my first version of the machine I will use a cheap (~100$) blue laser bought on amazon (kit), this will allow me to quickly be able to play around with the machine without having to worry about cooling, High-voltage mirror alignment etc.

So here I will detail the part list and suppliers (you should only buy the kit if your are in a hurry).

Parts list:

434nm blue laser pointer (Amazon)

3X stepper motors Nema 17 (ebay): 9,99$/pc

3X endsotps switchs (Amazon): 1,85$/10pcs

Laser window glass (at least OD4+) (LaserSafety):115$ 12X12 inch

ABS plastic for printed parts

Ramps 1.6 board (in the version 2 I will redesign a new board)

15X bearings (1.4mm)

3X GT2 gear

2X 1m of GT2 belt

5mm thick PMMA

7mm thick PMMA

Plywood or exotic wood (depending on the bydget) for the casing

The compressor (Conrad): 26$

12X M8 screws and bolts

15X M6 screws and bolts

Laser rated glasses (LaserSafety): 229$ (I had a pair of glasses thanks to my University so I didn't need to buy them)

What parts and systems will be made?

I will design and make all the structural and mechanical parts, I will make the power board to drive the laser and the casing for the entire machine including the air assistance (which comes from a compressor I bought) and the air exhaust (used a fan from an old computer)

What processes will be used?

I will make most of the structural parts by laser cutting, the mechanical pieces will be 3D printed and I will mill my board for the laser driver .

And I did a design for the casing that could be done on a laser cutter but the one I had during the class wasn’t big enough to do my job, so I ended doing it the old fashion way with a Festool and a ruler!

But I will inculde my design and also I might rescale the entire machine so it could be all done on a 600X300 machine.

What tasks need to be completed?

I need to:

Design all the structural parts (CorelDraw).

Design all the mechanical parts and retouch the structural parts to test them in an assemblie (Fusion 360).

Do some prototyping on the wheels that will be used in the carriage (3D printed).

Do all the test with the laser :focal length, mounting the laser, and insure the security by adding a control camera.

Design, test and mill a driver board for the laser.

Design the casing for my machine and rescale it for a smaller machine (if time left).

What questions need to be answered?

How can I drive my laser with a PWM signal? Which pin is ideal on the Ramps1.4?

How can I build something that others can/want to improve?

How to I adapt the Ramps board to control a laser?

Once my firmware is finished and loaded, what is the simplest way to convert a vectoriel file into a Gcode?

If I add an auto-leveling; should I put in on the same board? Or add it as a module so others can use it?

What is the schedule?

I already know that I will never complete all my goals during this FABACADEMY, but I would like at least to be able to present a functionnal machine that you can (almost) entirely build in your FABLAB.

My Schedule:

Finish all the design of version 1 by the end of this week (06/05/2016)

Start assembling and printing parts for first assembly test: 06/01/2016

Confirm all the design by assembly: 06/05/2016

Finish recieving all my commands: 06/10/2016) First test of the laser: 06/14/2016

I can control the machine with Pronterface: 06/15/2016

All the electronics is wired and tested: 06/17/2016

Final assembly and eventual correction and reprinting parts: 06/19/2016

That leaves 2 full days to work and the firmware and find the perfect software to drive the machine. Presentation at the FabAcademy: 06/22/2016

How will it be evaluated?

What I what to achieve:

Have a fully operational machine,

With a good engraving precision,

Flly enclosed-> class 1 laser when closed,

Humbly compare my project to the RepRap mouvment and see if managed to follow the same path.