MAKE SOMETHING BIG

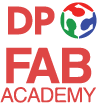

The goal this week was to design and fabricate a 2D object into 3D. Regarding the design, I wanted to fabricate a Kneeling chair.So i designed the 3D model in Rhinoceros.

The Material we had available was one piece of O.S.B in order to make something big with this

size 2500mm (length) x 1250mm (width) x 15mm (thickness)

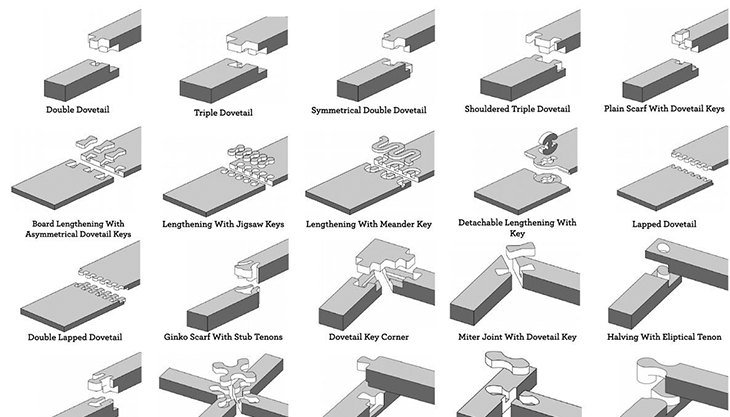

For this assignment we could'nt use nails or glue and before designing anything was important to have a look to the wood joints.

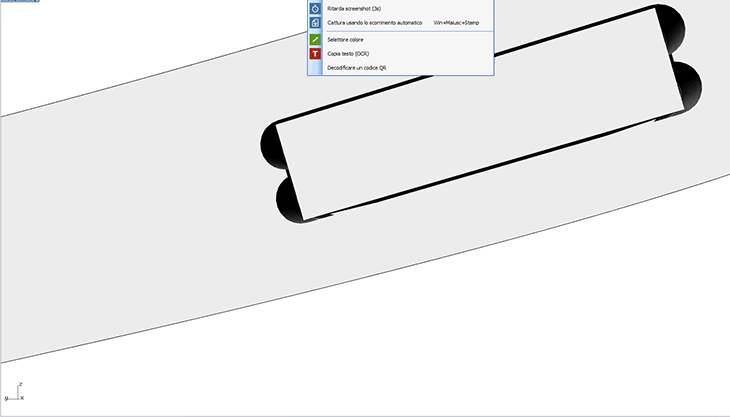

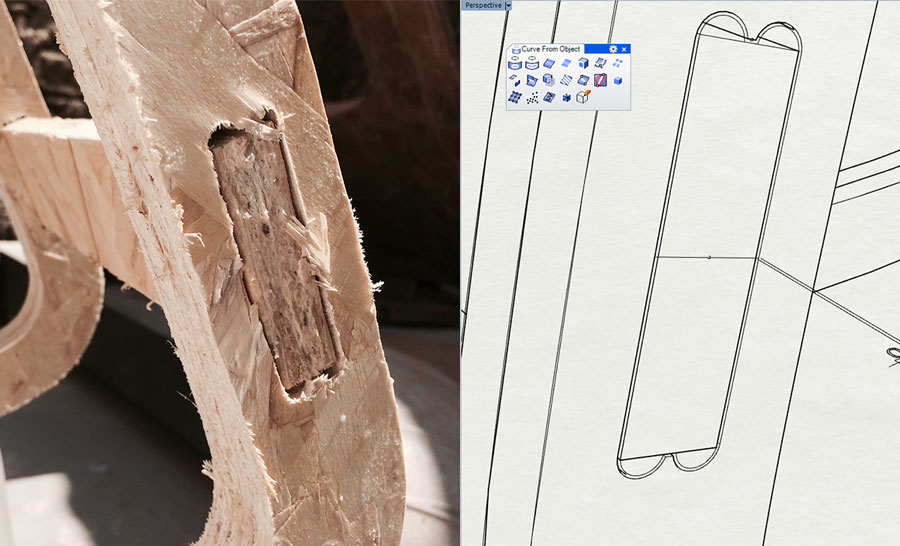

This model seems perfect also to join two pieces of wood through two sections, so I drew the dog-bone fillet.Before cutting my big piece of O.S.B I made a test to check the holes of the join 0.5 mm smaller than the piece for a better grip.

The final 3D model

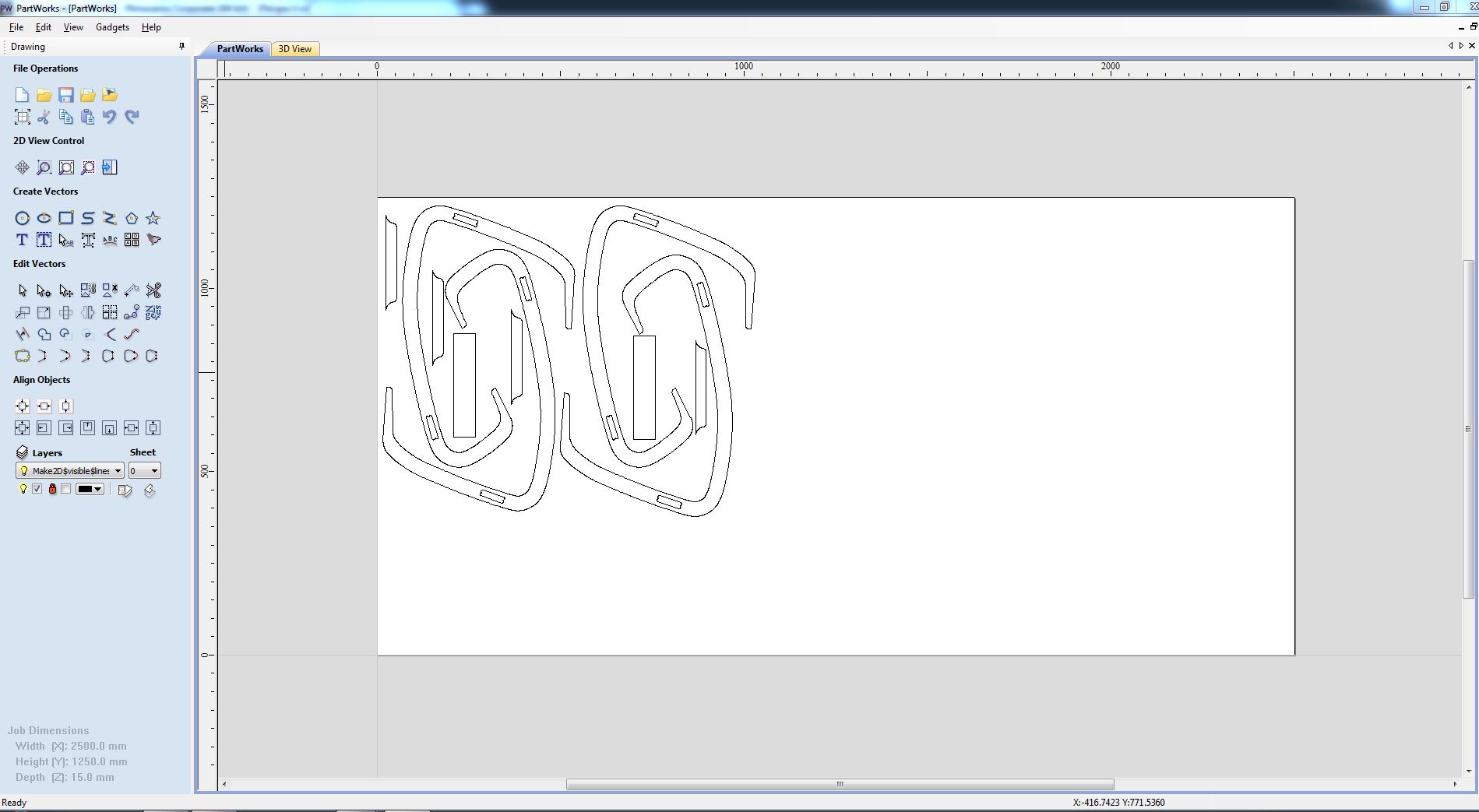

Partworks

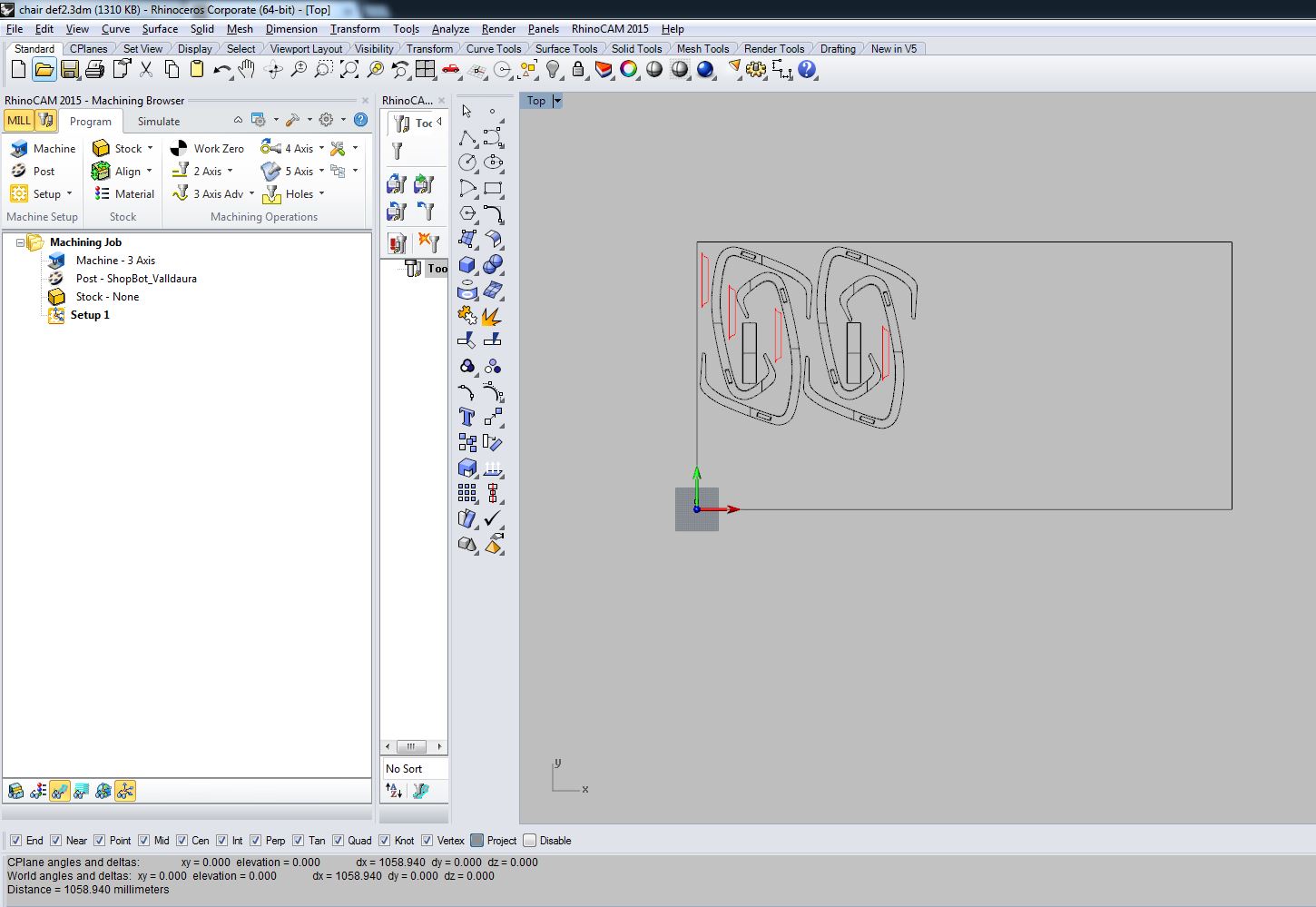

Once the Rhino file was ready I used the command Make2d in Rhinoceros to take their blueprints.

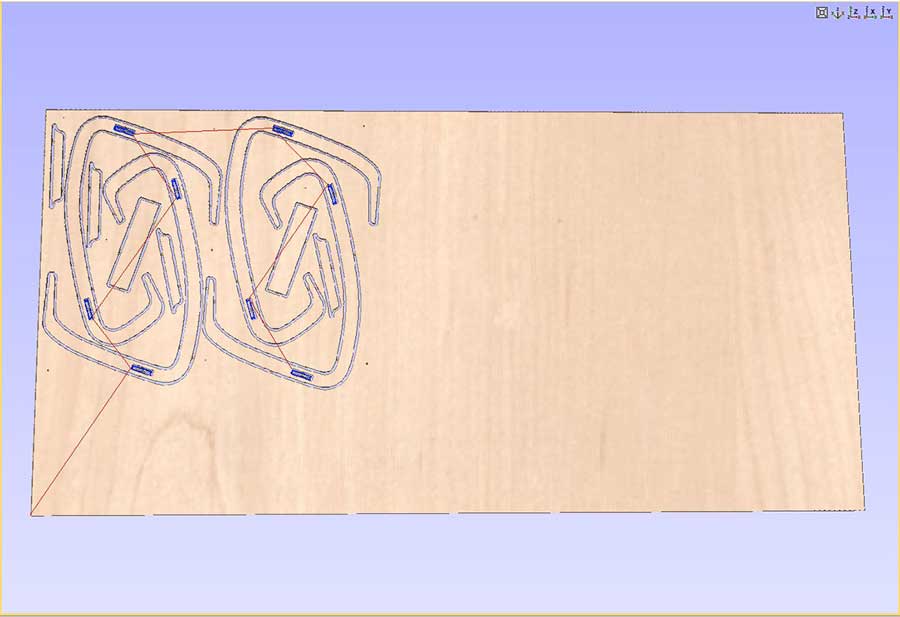

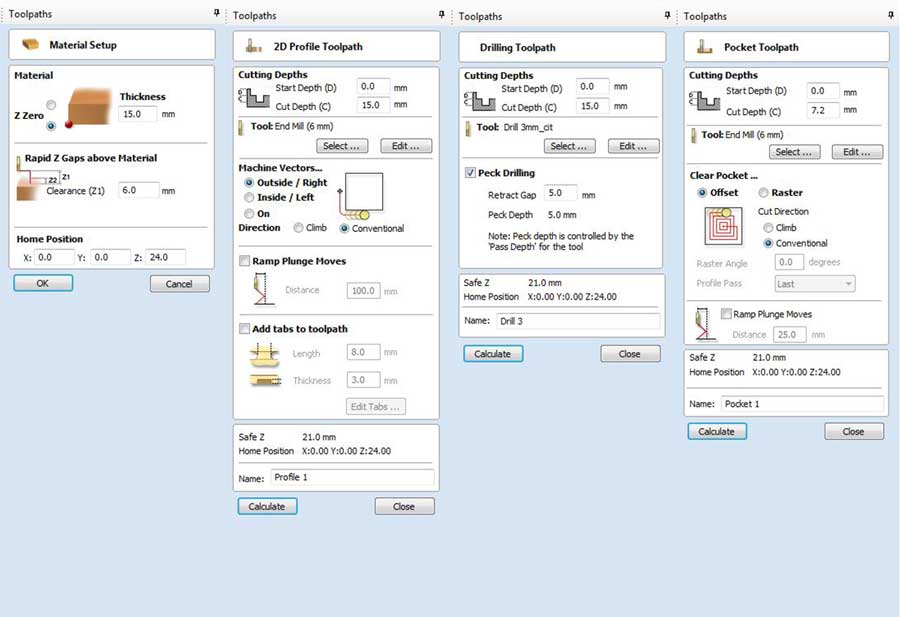

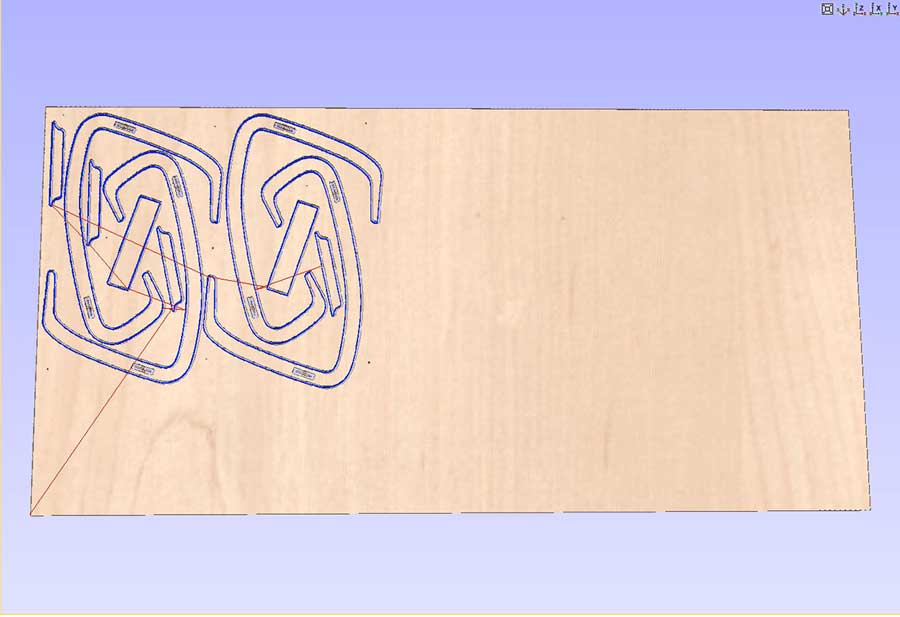

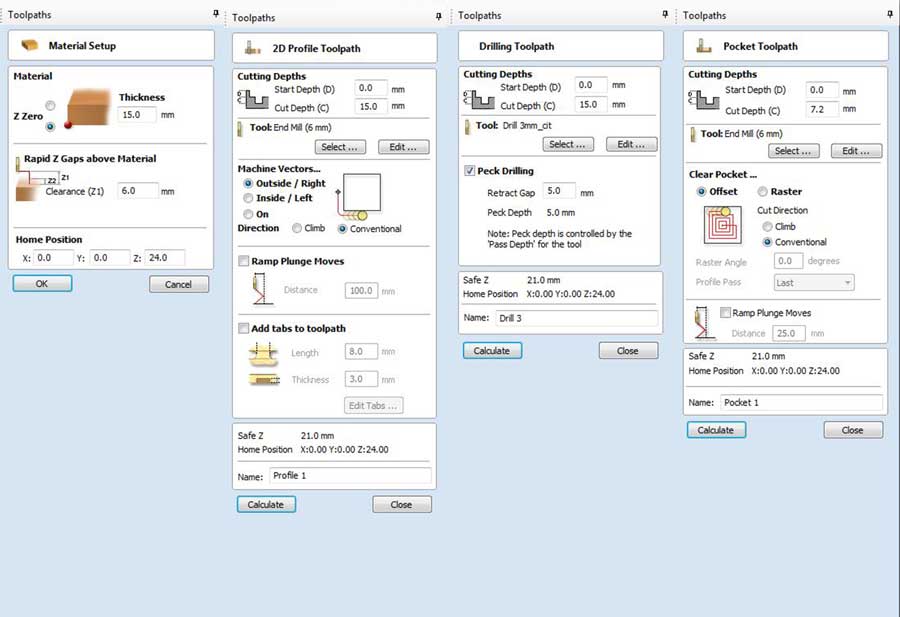

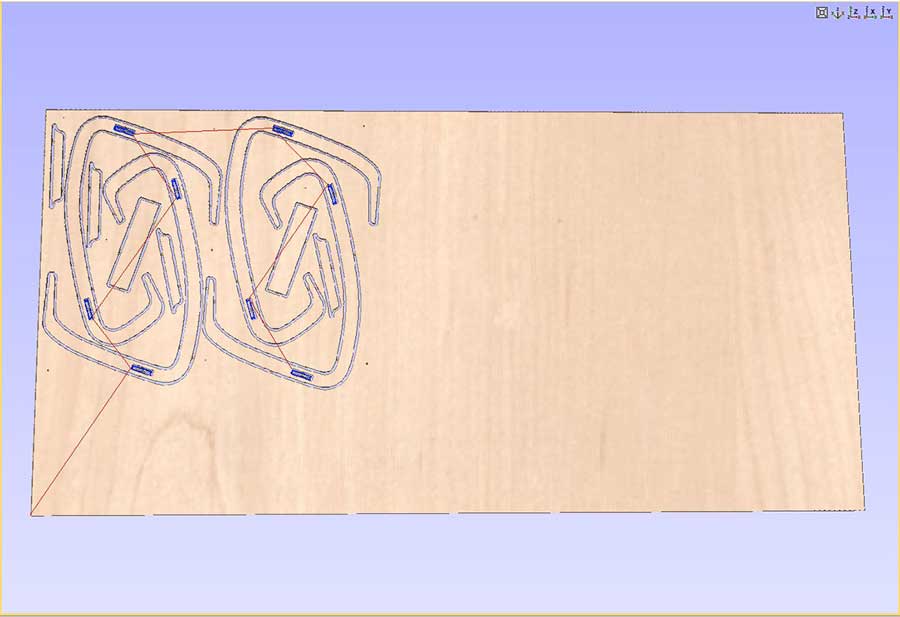

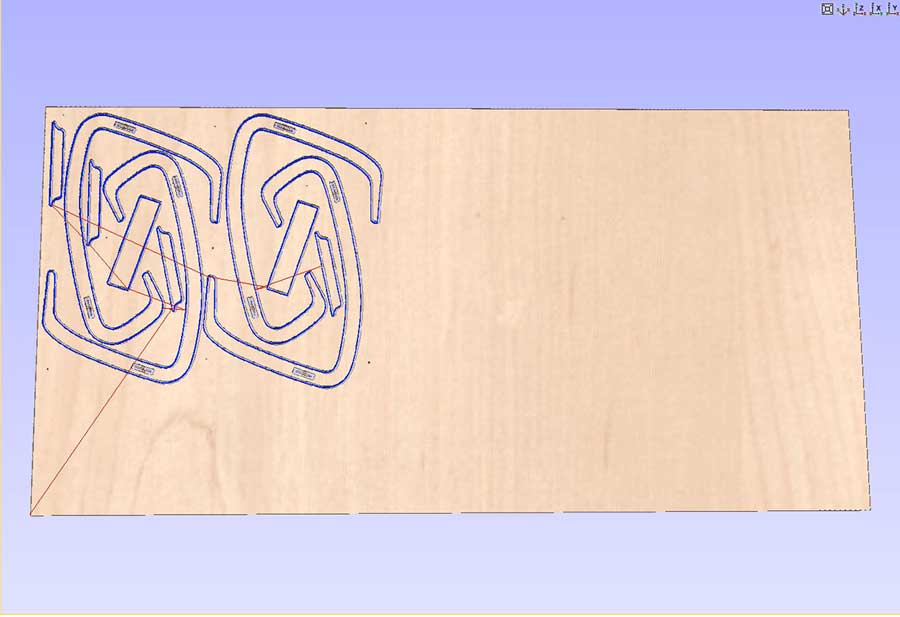

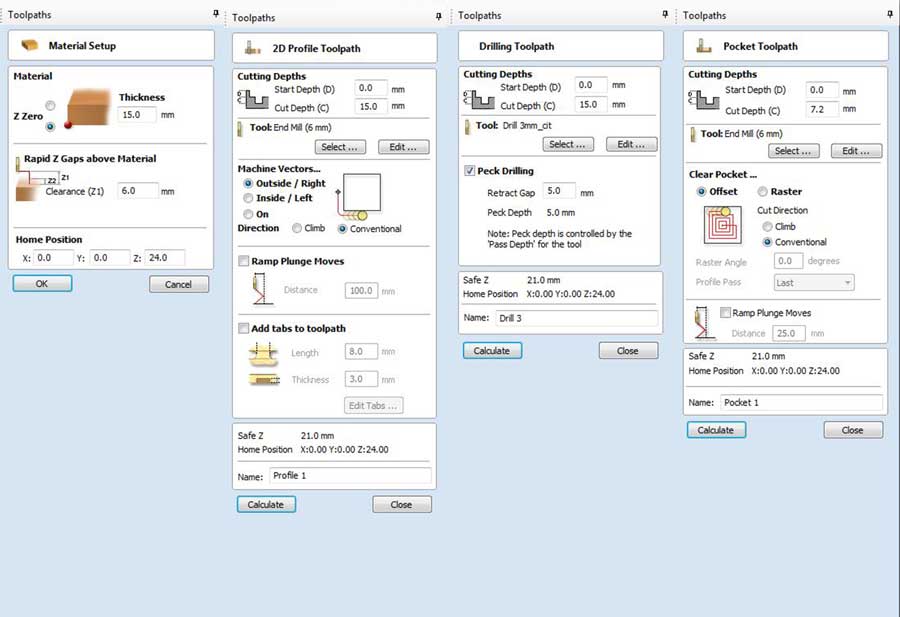

I nested them in a square equal to the dimentions of my O.S.B. to mill and I exported as a .dxf file to Partworks,the CAM program I used for making my G-Code.The first thing to do was set the size of working area in the Job Setup, then Z Zero and the Thickness of the material.Then I opened the .dxf file, joined all the lines as vectors,tool joint open vector under edit vectors,select CNC mill radius,add clamps (machine-> table clamps) to fix wood to the machine,select toolpath,the drill Endmill 6mm,cutting parmeters,feeds and speed with a spindle of 1200 rpm, feed rate 40mm/s, Plugin Rate 20.

At the end Save toolpath and Calculate and the program has elaborated a strategy in 2D for the cut.

PROFILE INSIDE

PROFILE OUT

Shopbot

PROFILE OUT

Shopbot

- Place the wood sheet in the machine and fix it

- Select and fix the tool mill.

- "home" the machine.(I used the arrows yellow console and moved the spindle)

- Add 20mm to the z-axis ( to avoid to touch the board)

- Remove the tabs created with Partworks with a hammer and chisel

- Remove screws using a driller

- Remove Material

Issue during the cut: I left not enough space between 2 parts of the chair and one of my OSB parts has broked a little bit. I used a sand paper to adjust it.

Final result

Considering the Material we used to complete this assignment the structure is not rigid enough. To ensure the requested strength of a chair while using the given Osb matarial I added 3 additional sections within this specific prototype. Only removing the additional structures would ensure the requested strength, using proper materials like Plywood or Wood.

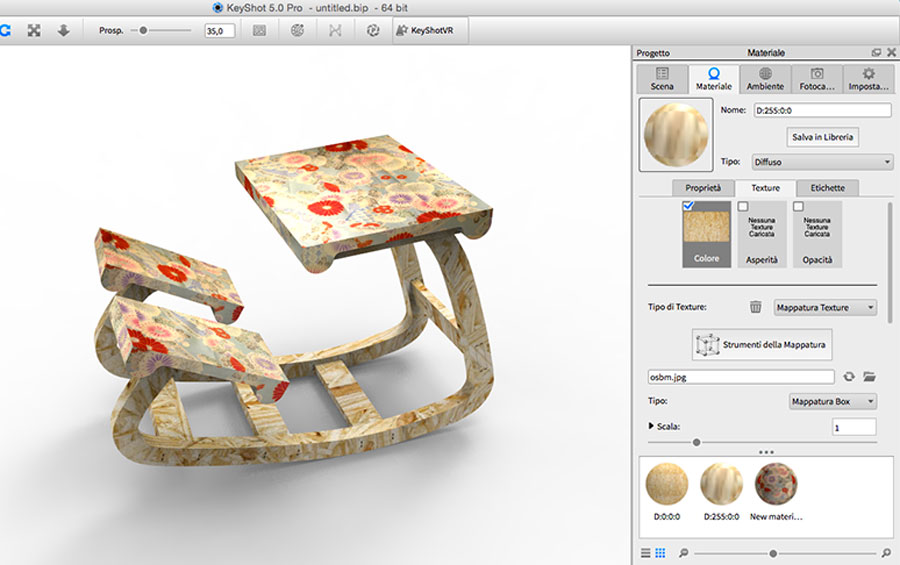

KeyShot render and the 3D model below.