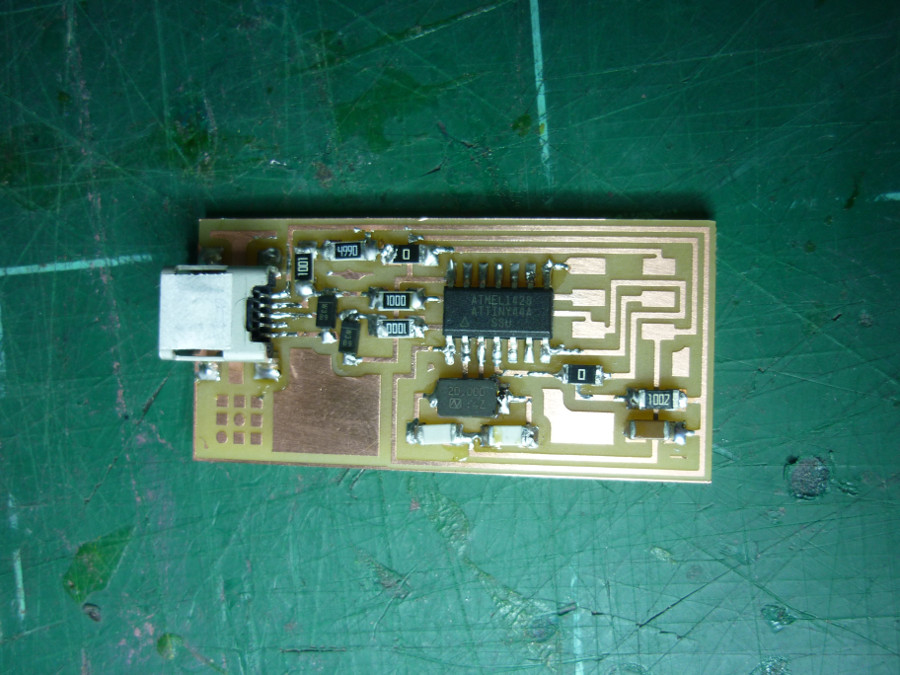

The assignment for this week was to Fabricate the FabISP(In-system programming). The FabISP is an in-system programmer for AVR microcontrollers that allows us to program the microcontrollers (brains) on other boards using an usb cable and the 6 pin IDC cable. It will be used several times along the semester so it is an important assignment. I divided it into several little projects:

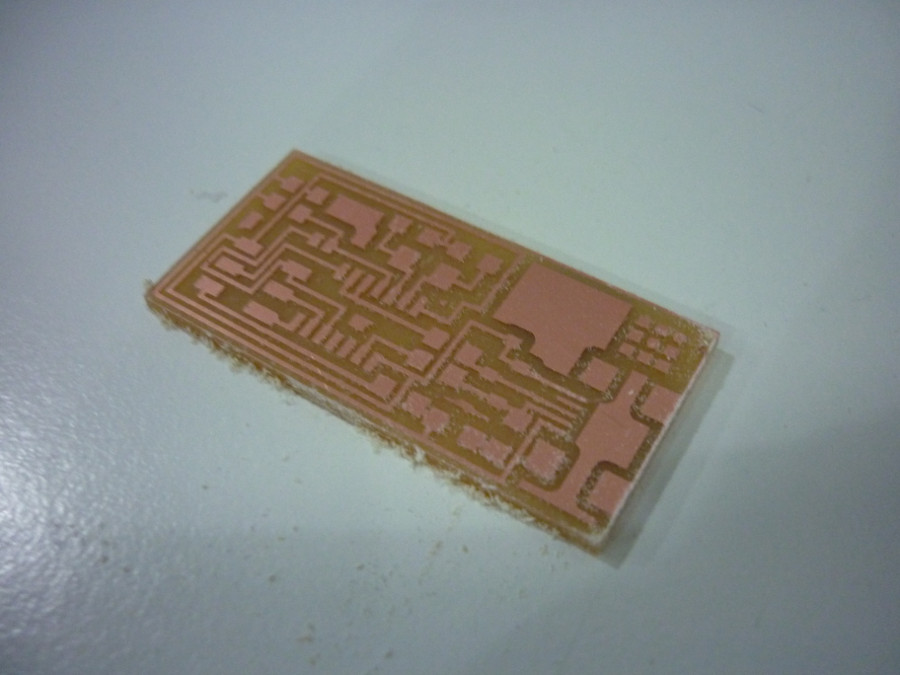

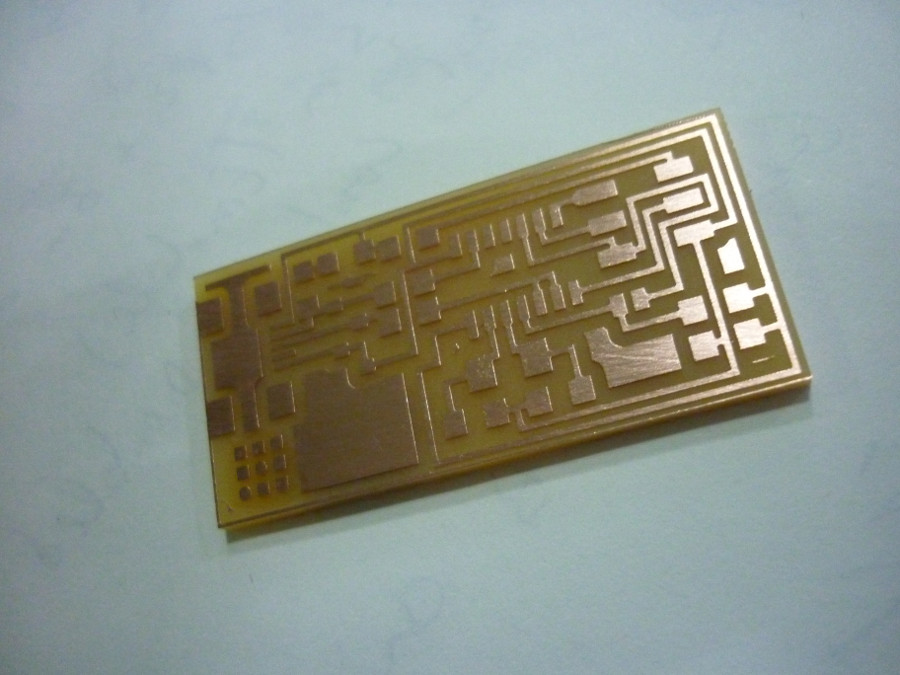

I made the ISP from a copper plate using Roland monoFab SRM-20 milling machine

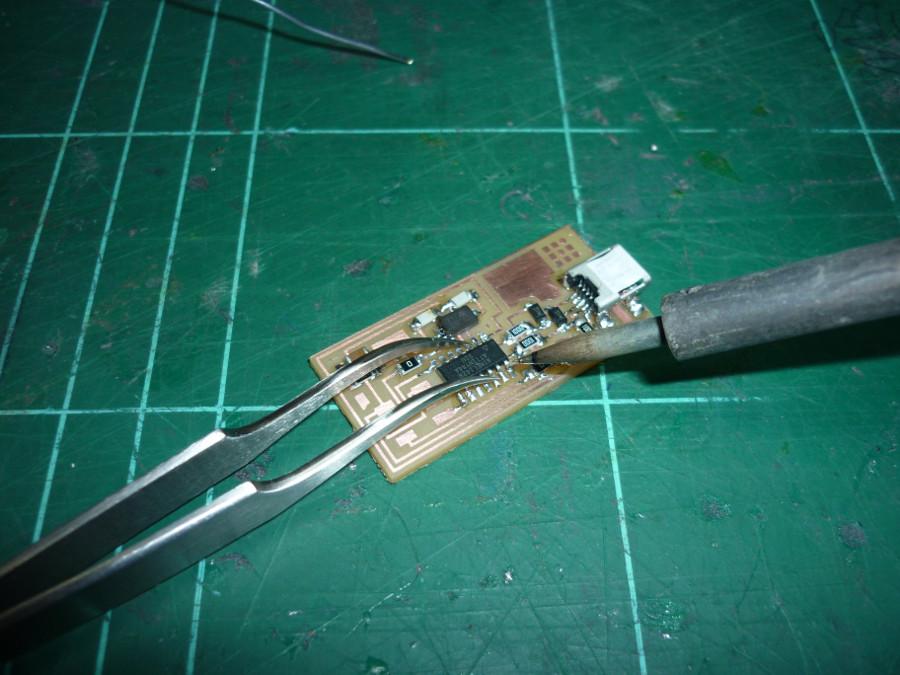

Before we start soldering there are some important tips about the soldering station and the working area.

Since I never soldered SMD components into a Pcb I had to learn, and nothing better than the EEV tutorials one big geek but with loads of information regarding electronics :

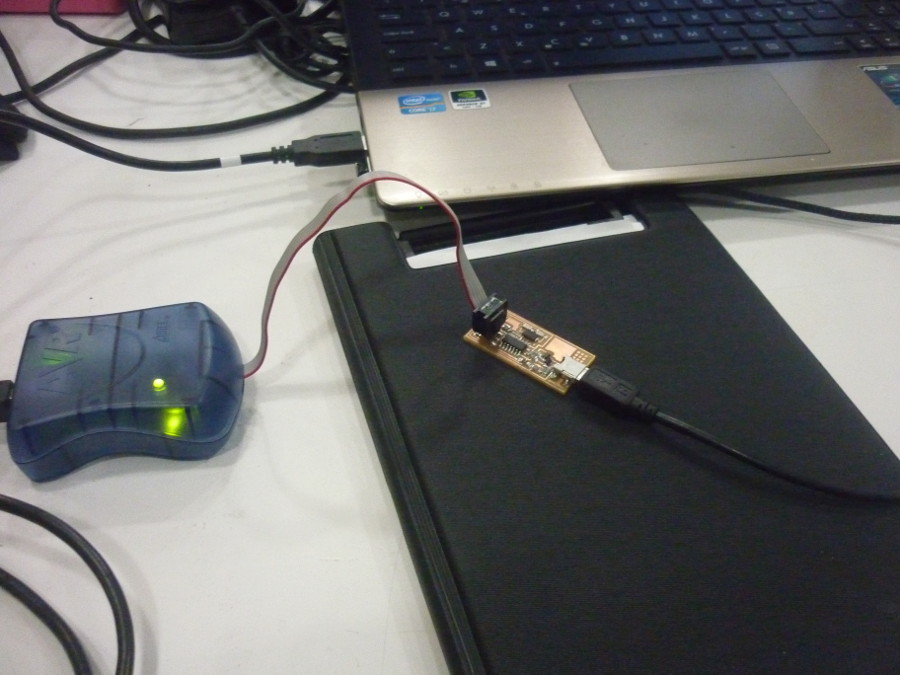

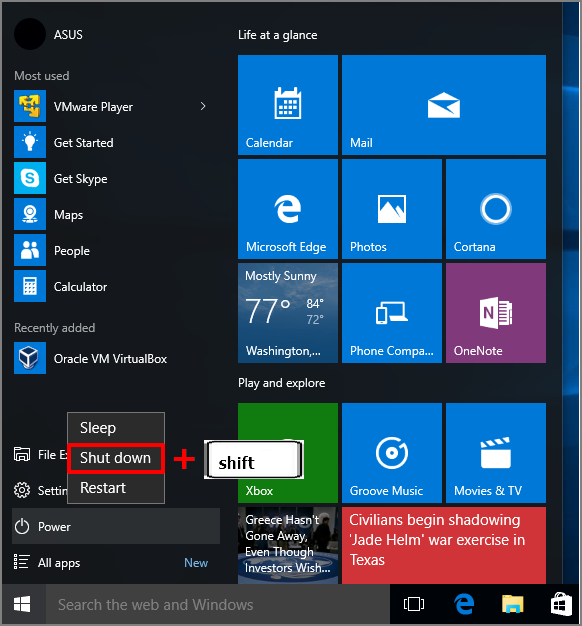

To Program the ISP I followed this Tutorial. Unfortunately Windows 10 isn’t capable of installing the AVR programmer drivers so I had to use the Ubuntu usb boot and used Linux to install the FabISP. Finding out how to Boot from an usb in Windows 10 was a piece of work.

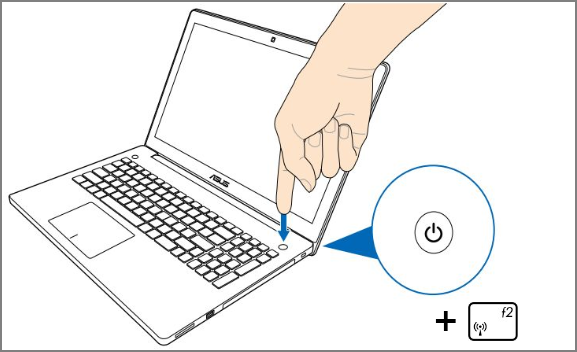

To go to the BIOS you must first Shut down the computer while clicking the shift key:

Then turn the computer On while clicking the f2 key.

Then turn the computer On while clicking the f2 key.

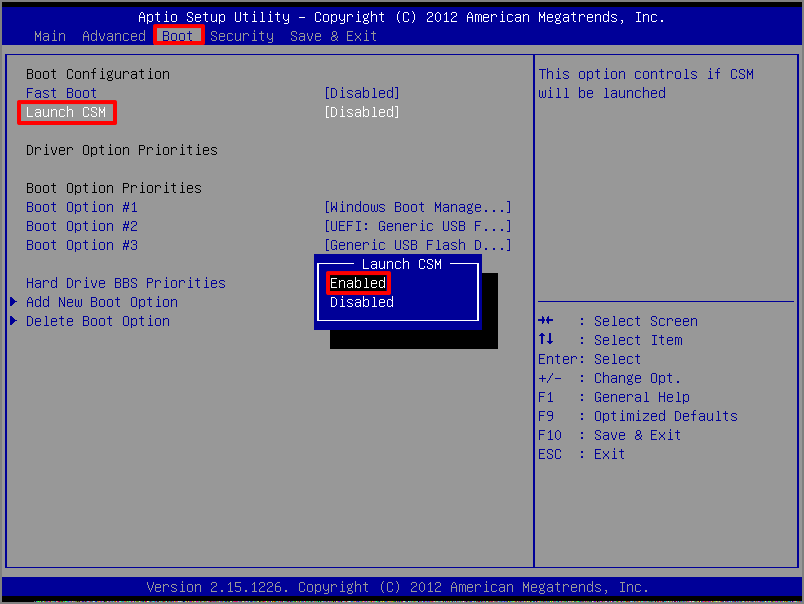

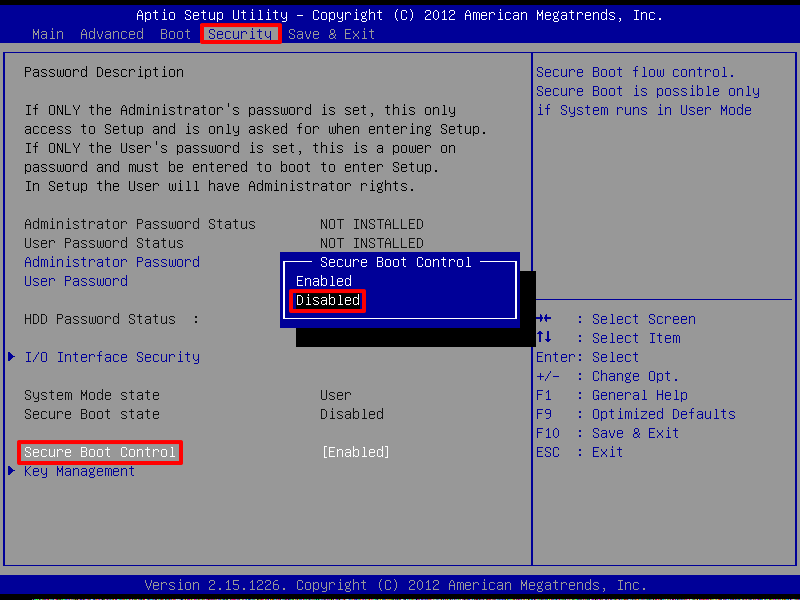

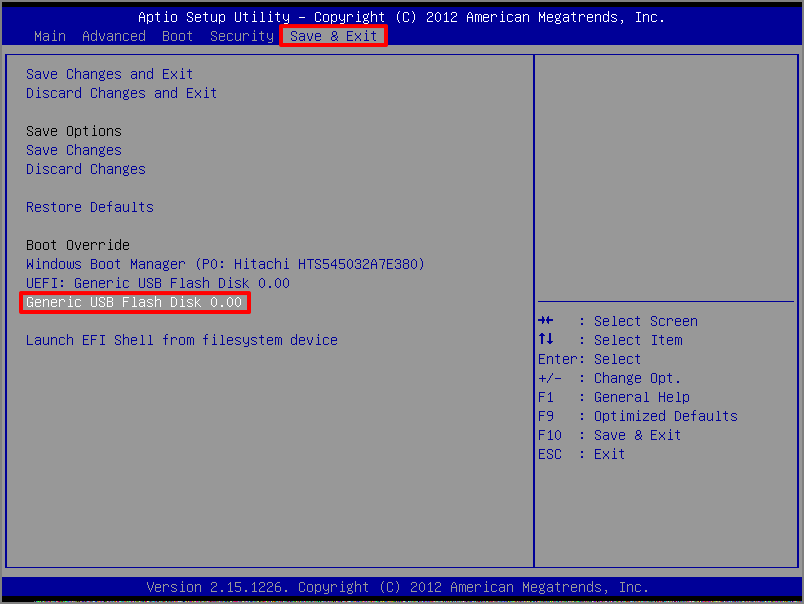

Once you are in the boot screen you have to go to the boot menu and Enable "Launch CSM" and in Security menu Disable "Secure Boot Control". Then choose boot from usb in the save and quit menu if it isn’t available you have to repeat the process to get to the Boot menu again and you will have the option to boot from usb.

Once you are in the boot screen you have to go to the boot menu and Enable "Launch CSM" and in Security menu Disable "Secure Boot Control". Then choose boot from usb in the save and quit menu if it isn’t available you have to repeat the process to get to the Boot menu again and you will have the option to boot from usb.

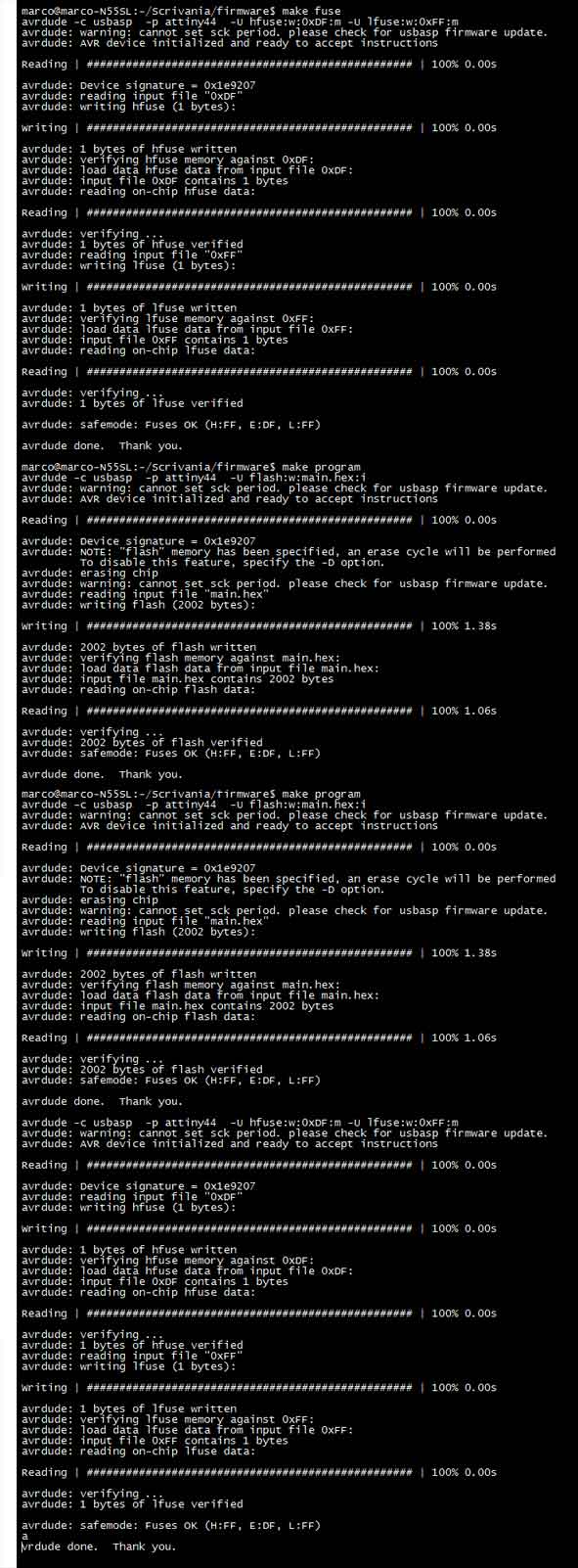

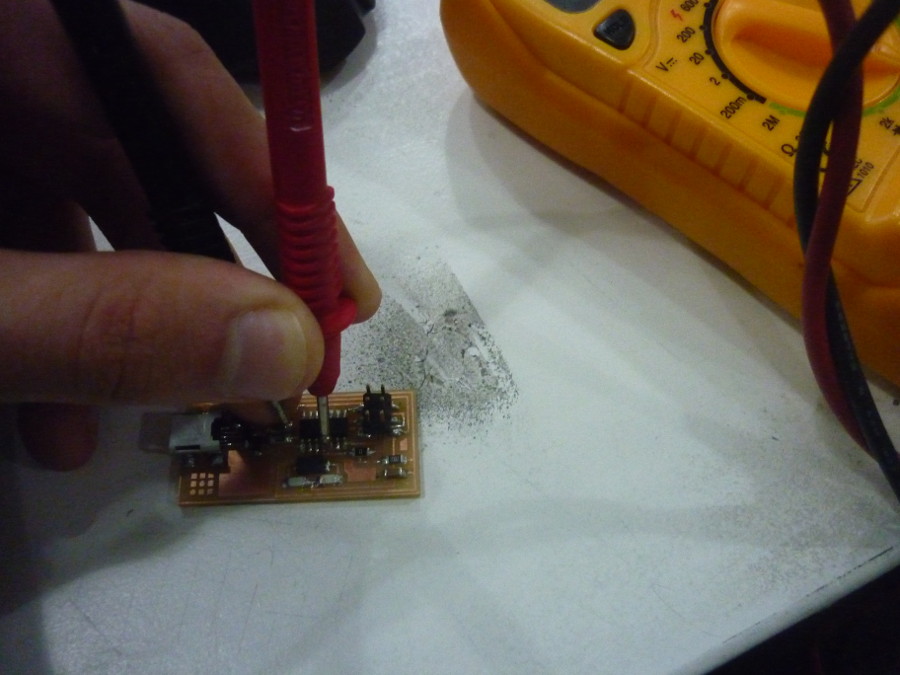

Once in Linux I started Programming the ISP as explained in the tutorial but I had a couple of errors mainly "Fuse error 1" and took me a bit of time till I figured out what was the problem, I had a small conducting material connecting two traces. After using a compressor to clean the board and re-tested the connections I retried programming the ISP and it was a success!!

Once in Linux I started Programming the ISP as explained in the tutorial but I had a couple of errors mainly "Fuse error 1" and took me a bit of time till I figured out what was the problem, I had a small conducting material connecting two traces. After using a compressor to clean the board and re-tested the connections I retried programming the ISP and it was a success!!