Week 9: Mechanical Design

Build a Mechanic Machine

For the assignment we have to design a machine to be operated manually. Inspired by Eva´s previous kinetic research we decided to build a primograph. Eva did the design, I kept track of the work processes for our documentation, but all three of us contributed video/photo material. We also did the laser cutting together and Elissa and I joined forces to assemble the little machine.

Group Members:

* Elissa Assaf

* Eva Blsakova

* Norma Deseke

Summary - CAD to CAM Process:

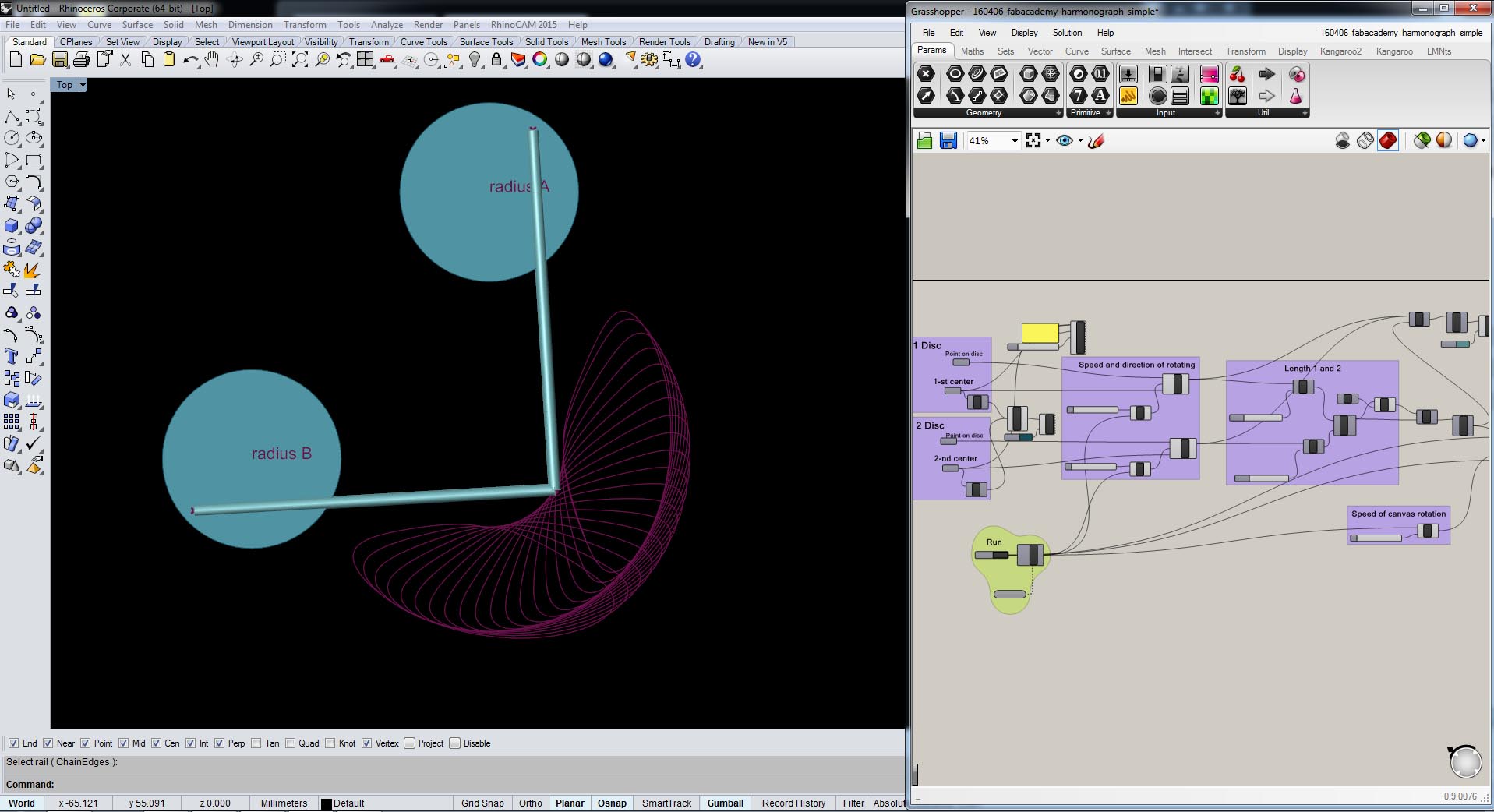

Software: Rhino and Grasshopper

Test Machine: Epilog Legend Laser Cutter

Test Materials: black and white Acryl, 3mm

Final Machine: Multicam 2000 Laser Cutter

Final Materials: MDF Wood,4mm

Other materials: 10 screws, 21 nuts, glue

Inspiration and Research

One inspiration for our project was the "Drawing Apparatus" by Robert Howsare, a primograph created from two turntables. Another stunning installation came from Copenhagen based artist Eske Rex created a drawing machine generating beautiful artwork. Eske Rex: "Drawing Machine is a construction involving two pendulums, each suspended from a tower construction and connected through “drawing arms” and moveable joints. A ballpoint pen resting on a drawing surface covered with paper is mounted at the point where the pendulums come together. The pendulums are set in motion by hand, and their movements are represented on the paper. The Drawing Machine serves two purposes: On exhibitions where the movements of the pendulums affect the entire room, and the experience engages the beholder’s body. While the rhythmic repetitions cause the beholder to pause, the drawing emerges on the paper. And as a tool where investigations on the relation between time and movement."

Computer Aided Design Process

Eva´s research included the preparation of this Video of ITUS kinetic morphologies.

Primograph Grasshopper Simulation from Elissa Sophia Assaf on Vimeo.

Primograph Simulation from Elissa Sophia Assaf on Vimeo.

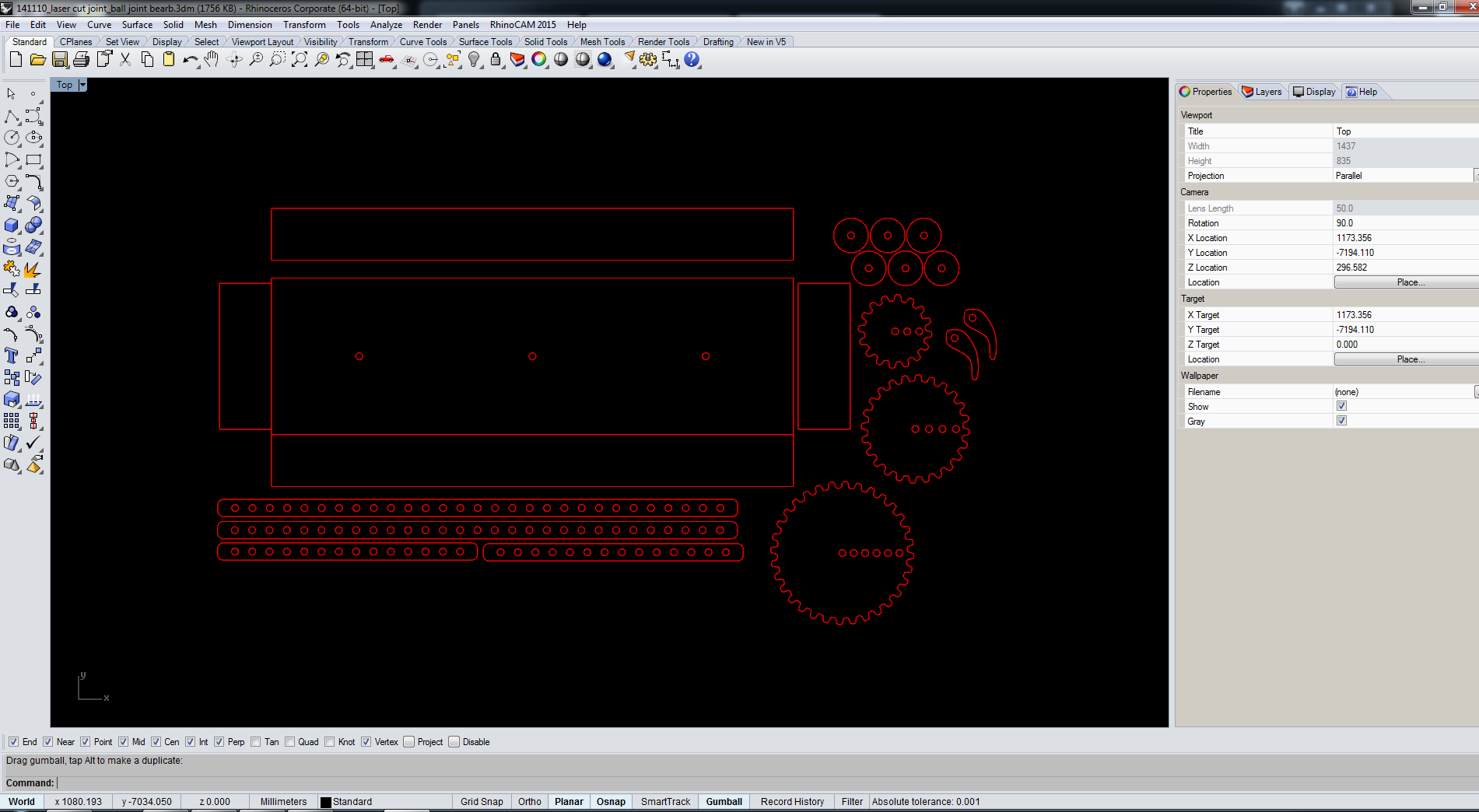

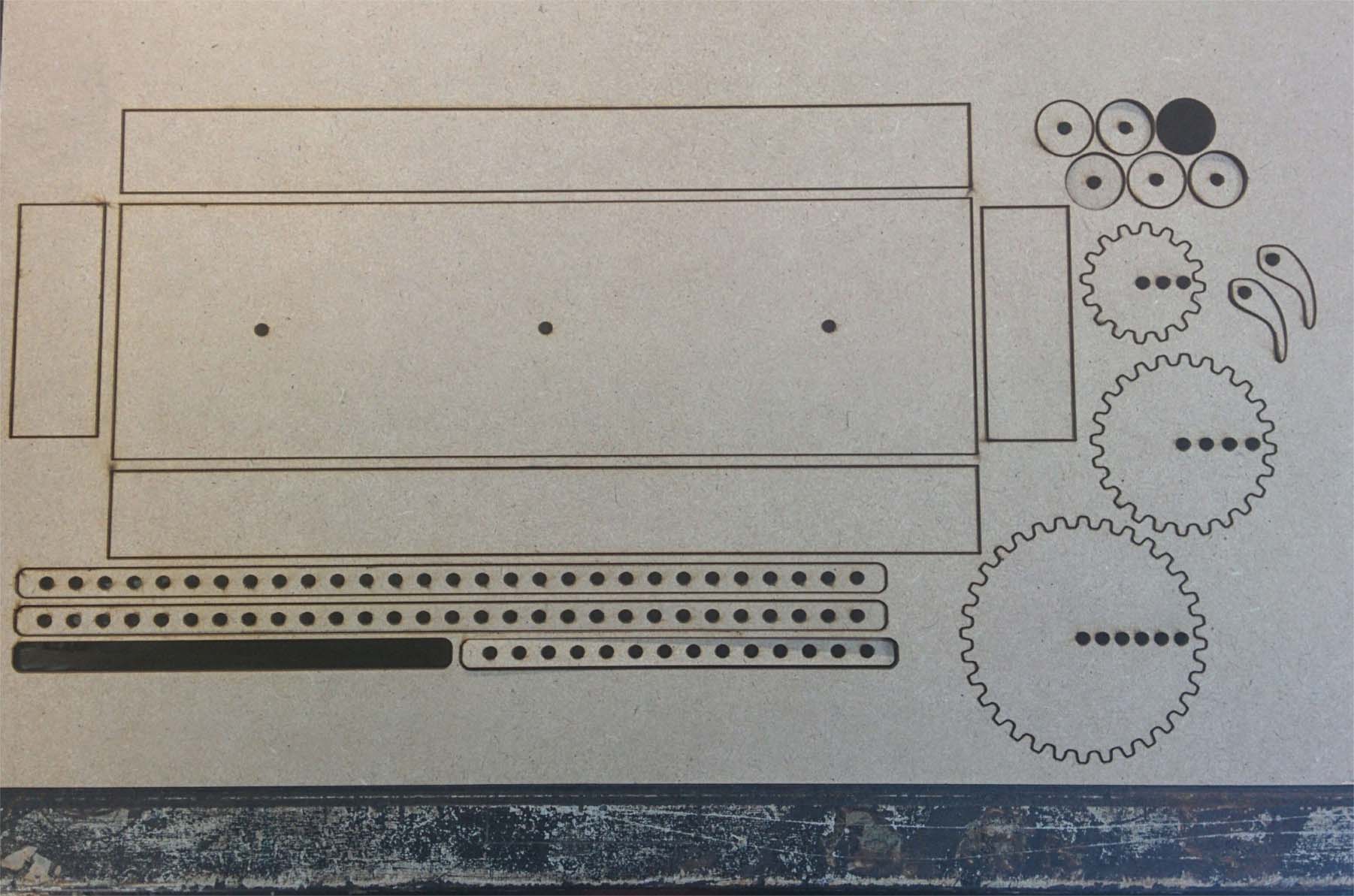

Computer Aided Machining Process

Material, Machine and Tests:

* 3mm black acrylic: 15-100-5000 (speed power frequency) on Epilog Legend Laser Cutter (load file, press 8- xy off, press go; move home manually; press 7 - adjust; press 9 - focus; press go)

* First test: didn't cut through

* Second test: decrease speed to 4%, still not cut; cut same place twice with same settings: cut but edges burned, would affect wheels and translation of movement. So change material.

* Third test: white acrylic also 3mm, 15 speed didn't work, 5 works, nice clear cutting edge.

* While it worked in the final test, setting out to cut the whole box failed. This was either related to the uneveness of the machine surface base or varying material thickness? Settings worked in some but not all parts of the material.Idea to use wood for arms and wheels, but based on previous tests wood has a texture which renders movement less smooth, whihc would impact on wheels trasnlation of forces (movement). We try anyway.

Change of Material and Machine: MDF Wood on Multicam 2000 Laser

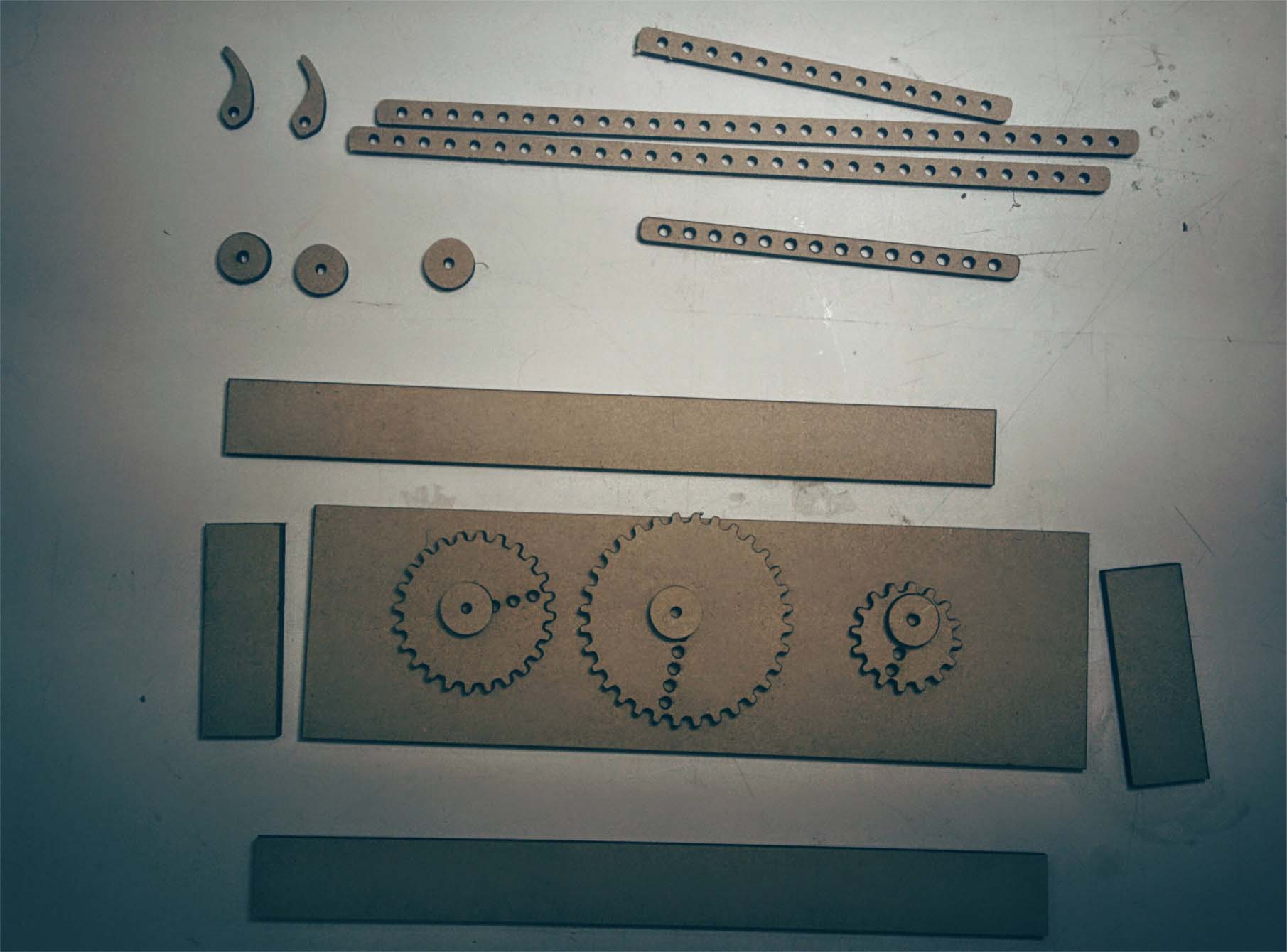

* The cutting worked fine, however when we assabled the box, we realised that we had misplaced the gears, they where actually not touching. So we went back to the design file and relocated the gears (Rhino). So we recut the box and assambled it.

The Result

The prototype works! However, there is lots of room for improvement next week:

* the pen holder doesn't do its job (ducktape!)

* a bit instable and wobbly (we need to locate the grip to move the mechanism differently - now the machine is in it´s own way)

* improve arm mechanism to generate different more interesting patterns

* decision needed if we either build a one motor or two motor mechanism

First Prototype Trial from Elissa Sophia Assaf on Vimeo.

Download All Files