Week 20:

prototyping the Final Project: the Pillow Alarm

- FIND ON THIS PAGE ::

- Prototype #1

- Prototype #2

- Master Plan

- Render process

- Remaining Questions

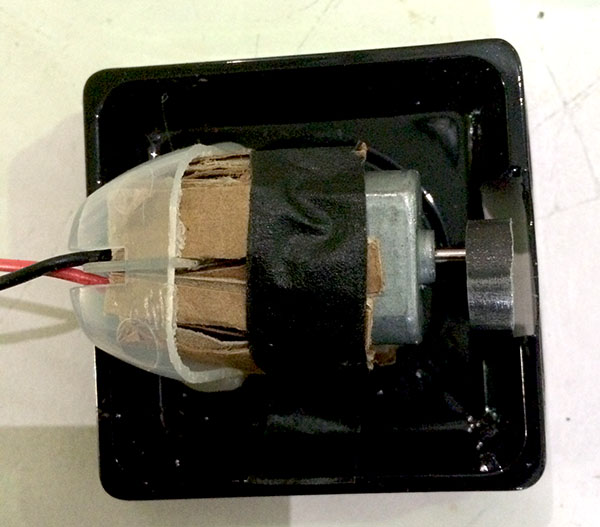

Prototype #1

Here is the motor in the case. I was going to add the foam, but the case was too unreliable, so I designed another.

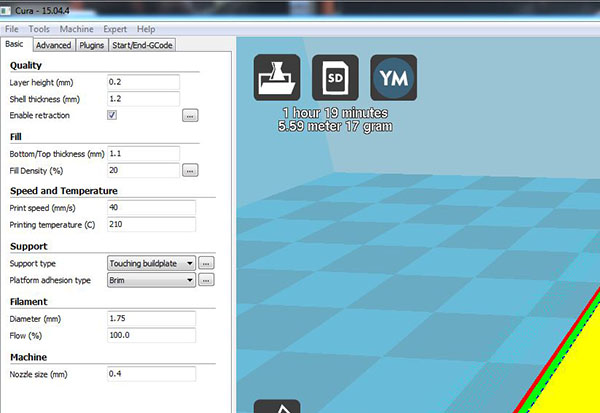

Settings for the Formbytes small 3-d printer:

FILES, MOTOR CASINGS

3-D files for Formbytes:

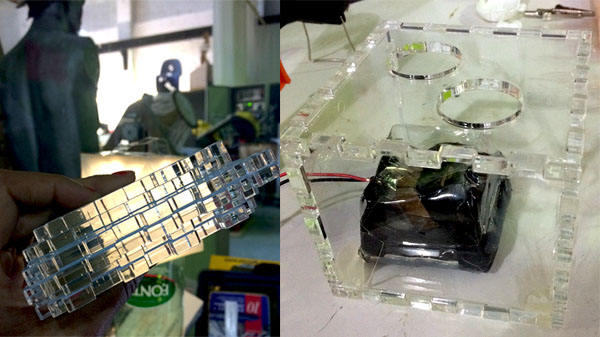

Prototype #2

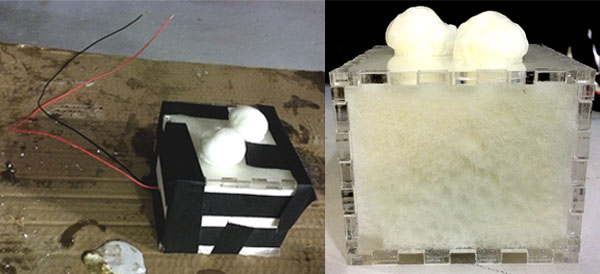

The foam was molded in an acrylic box cut on the Trotec laser. To make the box, I used the Inkscape extension "Tabbed BoxMaker," which worked almost beautifully. Next time change kerf for a better press fit; this time had to use a little hot glue.

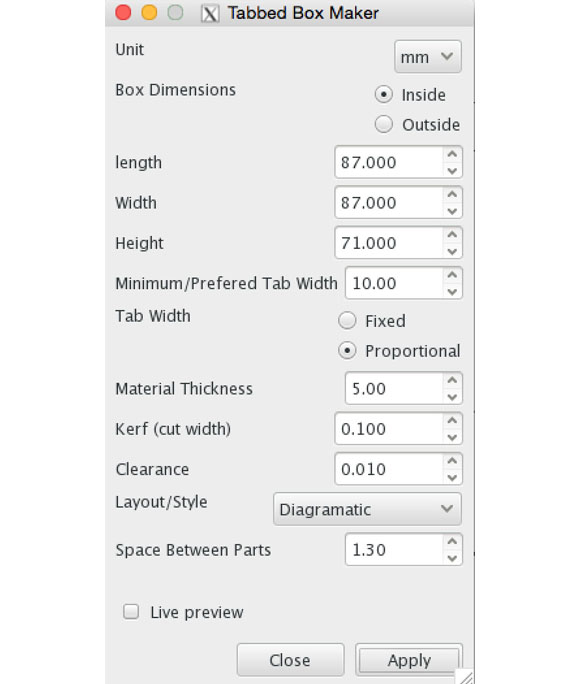

Settings for the Tabbed Box feature in Inkscape:

The molding and casting and its result:

I used FlexFoam-iT! 7FR from Smooth-On, bought at FormX near to IAAC. 1kg for 24,75 EUR. Also needed release; the Universal Release we usually use reacts with this material. Bought SuperSeal & Ease Release Kit, .11kg for 9,90 EUR.

Notes on the Trotec:

Took 3.5 hours to make a small box on the Trotec Laser Cutter. It has a totally not-intuitive software interface.

- SETTINGS for 5mm acrylic: .1 speed and 100% power

- NB: if you try to do it like Epilog, and use display colors to differentiate powers, this does not seem to work (thank you, Ingi, for this critical tip!)

- How to send the file to cut:

- save .dxf

- open in Rhino

- send to print specifically the layer you want, make it black, set all other layers as "hidden"

- in the Trotec's print dialogue, change the settings of the black layer

- Things I forgot:

- to check kerf settings on a sample!

- holes for various parts, such as the wires coming out and pouring the casting material in, as well as a breather hole; I rectified this in the file and sent it to print a second time

FILES, ACRYLIC BOX

Lasercut files for acrylic box:

3-D files for Formbytes:

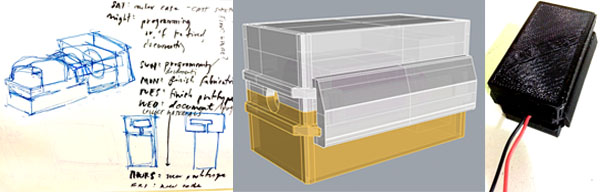

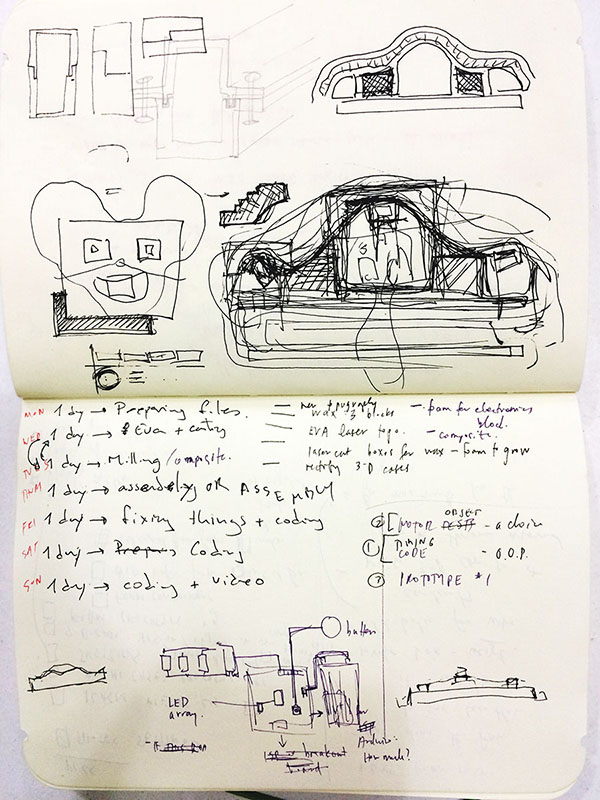

Sketching the Master Plan

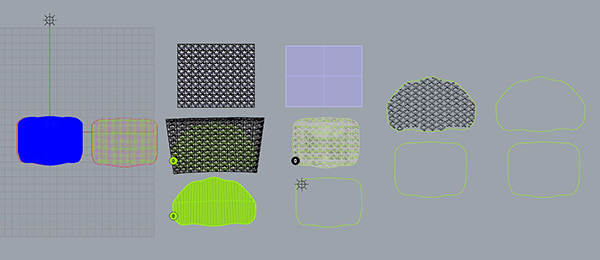

Render process

The idea for a final form is to have two layers of stretch fabric, the outer with some cuts in it to reveal the inner layer. The outer in a neutral color like gray, then the inner in a bright color.

And questions left ...

- What is the deadline? How much time do I have left?

- The deadline is in one day, but there was confusion in our lab about this, so I expected to work another 8 days.

- What tasks have been completed, and what tasks remain?

- The project meets its basic goals of being a functioning package. What remains is improving the code, adding a Neopixel strand to visualize the timing sequence, and creating a more handsome fabric covering.

- How will I complete the remaining tasks in time?

- I am stopping the development of the more alluring visual aspects and also cutting short my deep dive into object-oriented programming in order to wrap it up now.

- What has worked?

- The form is interesting, and the feeling of the motors provides some delight. I have immensely enjoyed the process with the coding, though the results are much simpler than what I actually explored.

- What hasn't?

- I have not succeeded in making a code with no delays. I also did not get to doing a re-working of my mesh in order to do a pattern overlay that hugged the contours of the form, that I would have used for laser-cutting a patterned covering.

- What questions still need to be resolved?

- I am not yet sure how to run NeoPixels as C objects so that the motors and lights can activate without affecting the overall timing of the sequence.

- What have you learned?

- I was focused on learning more sophisticated 3-d modeling techniques, and I have made a complex and intentional form. I have also learned to leave more time for coding, as I like to have elegant, rather than merely functional, code.