Week 05:

3-D Scanning and Printing

Objectives

- Identify the advantages and limitations of 3D printing and scanning technology

- Apply design methods and production processes to show understanding

- Explain additive vs subtractive manufacturing

- bonus: notes on settings and set-up for an Ultimaker 3

Software

- Fab Module for Roland Modela as a 3-D scanner (last week we used this machine as a PCB milling machine)

- Structure scanning app suite (to turn iPad into 3-D scanner)

- Meshmixer

- 123D Catch (from Autodesk)

- Tinkercad

- Cura

Machines

- Roland Modela

- Structure scanner + iPad

- RepRap 3-D printer

- Ultimaker 3

Design Rules (i.e. limitations to consider)

- SCANNER DESIGN RULE: flat; takes a very long time; about a 6mm long object took 20 hrs to scan with the Modela

- PRINTER DESIGN RULE: clean, no overhangs, tensile strength considerations of the filament (you can make a replacement part with the right shape details that doesn't have the flexibility / durability to function reliably)

Practices

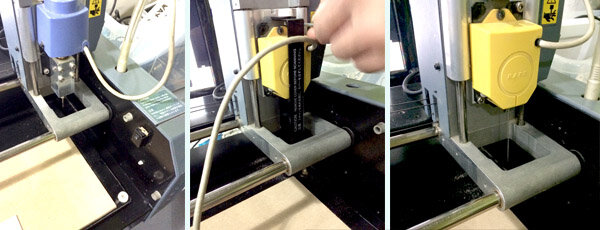

Scanning using the Modela

Change the bit on the machine from a milling / cutting bit to a poking / scanning bit. The Modela uses a needle and piezoelectric sensor to poke the object to scan it.

>

>

Put the piece on the underlay. It's attached via double-stick tape to the bed and to a few bits of cardboard to support it so it lies flat.

Determine a bounding box for the scanner head via Dr.Picza interface.

Scan.

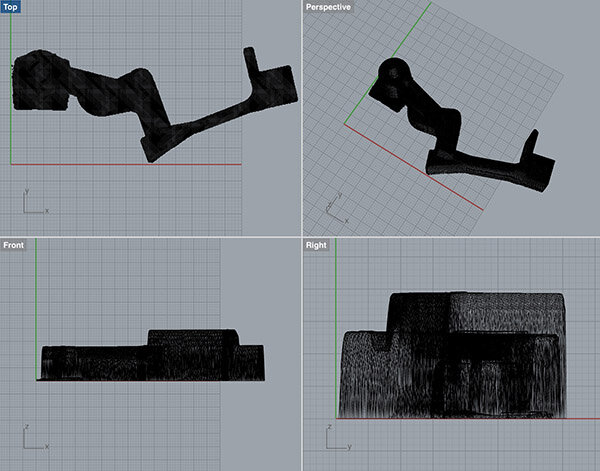

After 20 hours of those little hunt-and-peck-and-judders! We have a scan of a latch for a Brompton carrier block (mine never got installed: a shop error). The file can go into Rhino for clean-up and eventual 3-D printing.

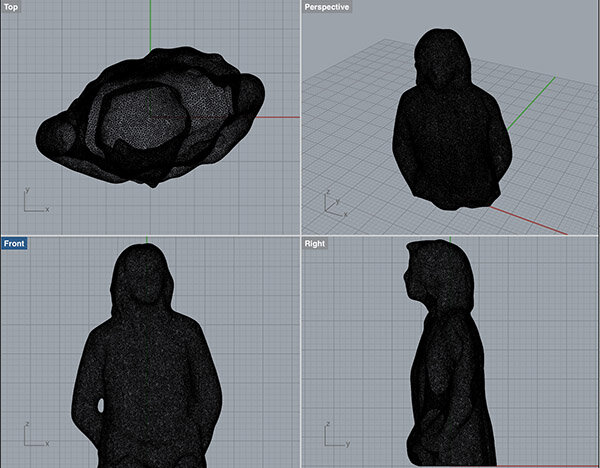

Scanning using a Structure Scanner

Donato has a machine called a Structure Scanner, which attaches via a cable to an iPhone or iPad. We downloaded a few apps to make it work.

- itSeez3D ~ integrates the 3-D information (polygons) and maps color info to it.

- Calibrator ~ determines the range of the color info being gathered by the iPhone / iPad camera

- Scanner ~ translates image to polygons

- Structure ~ matches the depth data the machine is collecting with the color data stream from the iOS

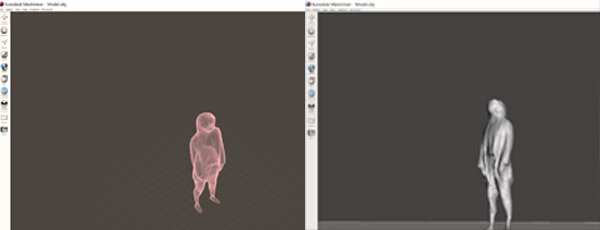

Using this suite, we tried a whole body scan. It was pretty unresolved as far as facial details go ~ I looked, more or less, like ET.

Donato and I went to a bust capture, hoping for more detail and less lump-like-ness. This worked a bit better. We captured a model after a few tries.

We altered it a bit in Mesh Mixer, using the "smooth" command till it was less bumpy. Then, I sent it to the IaaC cloud to go to print.

I had some trouble getting the file to show up in Cura, the program that translates the .stl into G-Code so the Rep-Rap, an Arduino-based filament 3-D printer, can read it. After re-sizing a few times -- the file export from Mesh Mixer was in micro-millimeters -- we found it was simply a matter of changing the viewport style in Cura. When we did that, numerous Janaki-busts appeared, littering the plane of play ...

Printing

* NB - As this was my first experience with 3-d printing, I didn't realize how many settings there are to adjust. I was just interested in achieving the object. Later on this page, dealing with the Ultimaker 3, I became more specific in how I was able to see this job. *

Chin. It's sticking out in space, unsupported. In the Cura file, the spot under the chin needs to be addressed with "bridges everywhere," creating beardy little filaments that must get cut out after the print is complete.

The code gets written to an SD card, which gets put in the RepRap.

The Rep-Rap base needs to be well-cleaned with a metal spackling tool, then it is sprayed with a hairspray-like product called "3D-Lac." This ensures the first layer of plastic doesn't slip on the glass plate.

Once things are sent to print, the tool tip of the Rep-Rap heats to 200 degrees, then the extrusion begins.

This object took 20 minutes. Then I waited for the material to cool from 50 degrees to 0 degrees before pulling it off the bed and shaving off its peculiar beard.

Elia did a simple camera capture moving around with an iPhone and his feet. For some reason, I failed to get the files he sent me to render in 123D Catch.

After processing through Autodesk's cloud, I received this not very useful file in return:

Empty. Although I tried it twice, I did not figure out why Elia got a result and I did not. I ran out of time to sleuth it.

Printing Test: Ultimaker 3

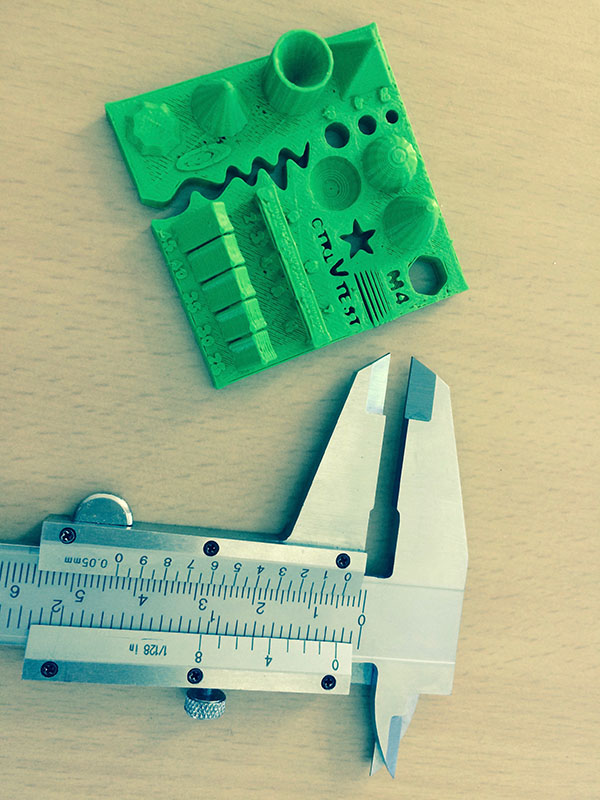

I also set up an Ultimaker 3. There are some pieces online to use as tests for calibration and quality of the extruders and settings on your machine. The Ctrl-V test is a popular diagnostic. So is Benchy. See the Quality Guide on the Simplify3D support page for excellent, clear help.

ANALYSIS, ADJUSTMENTS. The top layers of the control print aren't good, so I changed the Cura setting to increase the thickness of the finishing layer. To get a high quality print, the key is to go quite slowly! In general, if you can use material defaults for an Ultimaker, you will get a good result. If the material is not a UM filament, you can spend a lot of time tweaking and still get a sub-prime print. This is okay, in general, for school work. The real limitation is that for a good-looking, strong print, the machine produces best results at under 200 mm/s for PLA, and more like 20-40 mm/s for flexible filament.

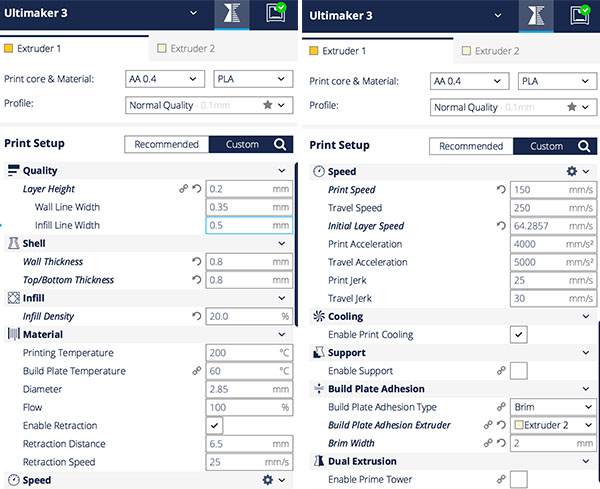

FINAL SETTINGS FOR THE CTRL-V TEST:

Because I help set this machine up in a school, I had a chance to compile a list of the material supports needed to use and maintain a 3-d printer -- the basic equipment:

- array of filaments

- 3DLac or spray as fixative; or glue stick

- spatula to lift pieces from glass

- blower to clean feeder parts (manual or handheld vac)

- hypodermic needles to unclog nozzles

- tweezers can be handy for cleaning / fixing

- glass cleaner

- rags

- acetone, to melt surfaces

- sandpaper for finishing pieces

Additive vs Subtractive

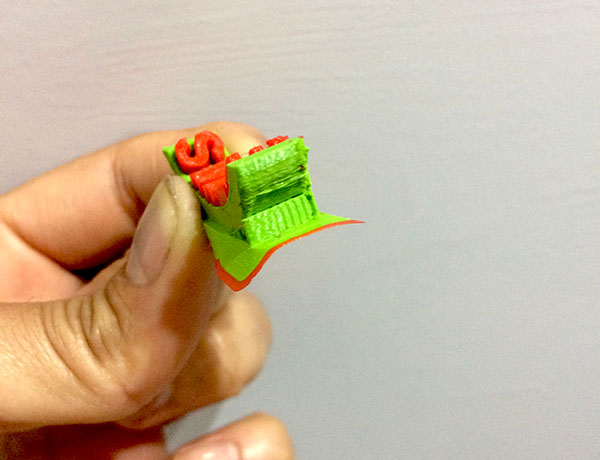

The 3-d printer accumulates layer one on top of the other, and the layers stick to each other. A subtractive process, such as milling, takes material away from the top on down. So there are design features that are possible with 3-d printing that are not possible with a mill. This simple object, the "Smile," is an example. The letters on the curved surface are tilted, so that the space between the letters that is nearest the viewer is smaller than the spacing closer to the ground plane. That would be impossible to do with a mill bit that was removing material from the top down. It would be interesting to push the effect to a greater extreme in another test.

Also, this was made with Ultimaker 3's dual-extrusion capacities, thus fusing two materials. That, too, is a feature not available in subtractive techniques.

COMMENT ON SETTINGS FOR SMILE PRINT -- I used Ultimaker brand filaments and default settings with the following tweaks:

- I added 5 degrees to the extruder for the red PLA because it was not looking juicy

- the piece does not look so nice on the overhangs; I would have to add a support grid or adjust the file so that the angle is less steep

Some Interesting Ideas

Monday's Recitation: Vinay Gupta

Gupta's main pursuit is figuring out methods of disaster preparedness. It is easy to start off with skepticism about this guy, because he is a libertarian and supports bitcoin and guns. However, the way he offers specific evidence of government oppressions such as genocide and monetary policy control, I start to listen, and listen more carefully ... and find, by the end, that he is knowledgeable and interesting. One of the most glamorous things about him is his certainty. It is a quality I find it impossible not to admire, because it is counter to my own personal beliefs (I hold a near-religious conviction in growing the human ability for uncertainty). Gupta has developed a low-cost housing method called the hexayurt, made from 12 sheets of plywood, fit for refugee shelters. At present, it is mostly used at Burning Man. He has specific advice about how to survive the collapse of cities: store 3 days of food and water, giving the government time to organize themselves. Survive pandemic: keep a month of food and water in your house so you don’t have to leave the building for 30 days. Gupta has synthesized ideas of the sharing economy, of blockchain currency, of massive change ~ many of ideas of our previous speakers. He has a total vision of a fairly jolly but lawless world that mostly regulates itself according to laws of human nature. I’m not sure if I care whether he is right, but he has given me the chance to think about social collapse in a pragmatic rather than avoidant way. I find that kind of chipper.

I was not able to attend the actual recitation, so I watched an interview Gupta did with London Real instead.

Actually, when he makes claims like “Libertarianism is the only defensible philosophy,” I have to shake my head in awe at his conviction ~ and because I disagree so completely that my jaw drops at his assertion. However, again, again ~ I am an American, native born, and I have never truly feared starvation or homelessness. There are perspectives of real deprivation that I do not grasp. And though I am really not sure that Vinay Gupta grasps those perspectives in any way that is not strictly intellectual, at least he reminds me of what I feel I can’t honestly pretend to know.

IAAC Winter Lecture: Reiner de Graaf

Reinier de Graaf, a partner from OMA who gave the Tuesday IAAC Winter Lecture, detailed his current struggles with pseudo-architecture (urbanists and corporations using the language of architecture), pseudo-democracy (governments who offer ballots but determine the outcome of the count in advance), and pseudo-capitalism (a fiction of a free market when it is actually controlled by a vanishingly few people).

de Graaf and Gupta seemed to be reacting to what a “total system” could mean: a plan for acting in the midst of mass chaos. Gupta feels he has a handle on it; de Graaf feels no handle is possible, and the condition of the world is to legislate for a system that is impossible to predict and changing too fast to model. de Graaf suggests governing for the mega-region. To me, it sounds like Renaissance Siena, in a way: an economy tied to the land and the city tied to the land that supports it; a supply chain with some financial as well as ethical mutual obligations. One of the most beautiful ideas of spontaneous (meaning unlegislated, not rapidly emergent) social co-habitation of which I’ve ever heard is via Stephen Lansing’s 1970’s study of Balinese water temples (see this recent recap in the FT; there's some denser information via Stewart Brand). This involves religious belief to maintain the sense of ethical obligation which is, finally, a resource-linked obligation.

So, what’s the new motivator of a global ethics? This has got to be the wrong question, because it’s an impossible one to fathom. Think smaller, J. Let the world GIK it.

Some great things Reinier de Graaf said:

- Metaphors of architecture cannot be disproved.

- Short sleeves are a sign of an engineer.

- Dubai over the last twenty years is an example of things built without authentic demand and in a simulated free market.

- With regard to urbanization and mega-cities, GDP must remain ahead of population growth.

- He proposed governance by mega-region: “Get capital beholden to place."

- The essence of a functioning democracy is that top-down is bottom-up.

- One of the benefits of the Internet is that it reveals hidden majorities.

Events this week:

- I went back to the States and moved out of my house.