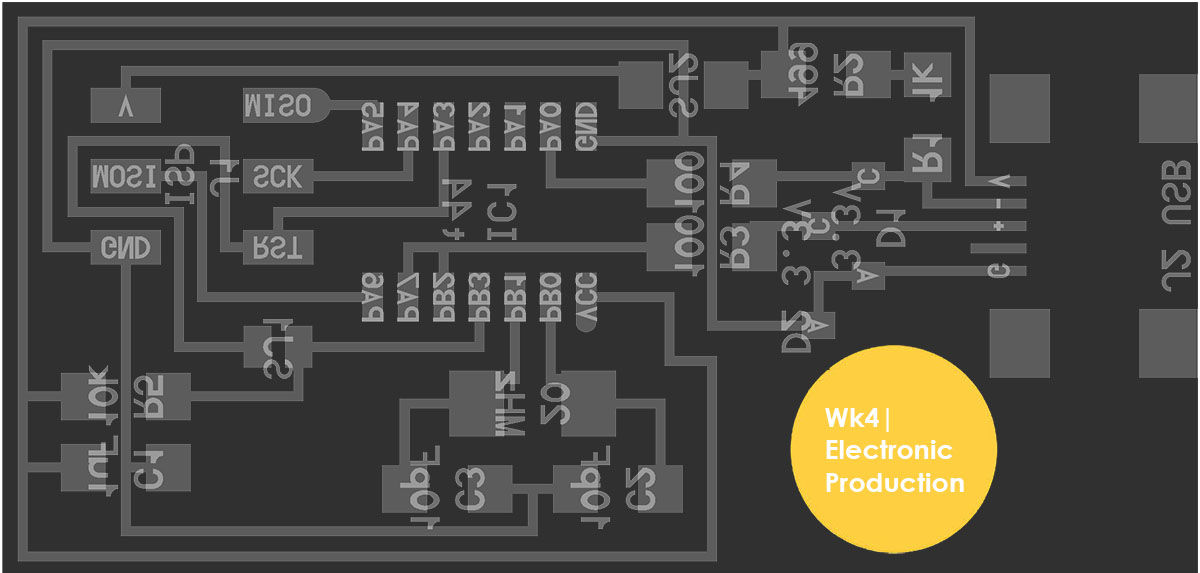

Electronic production

Task: |make an in-circuit programmer.

Objectives:

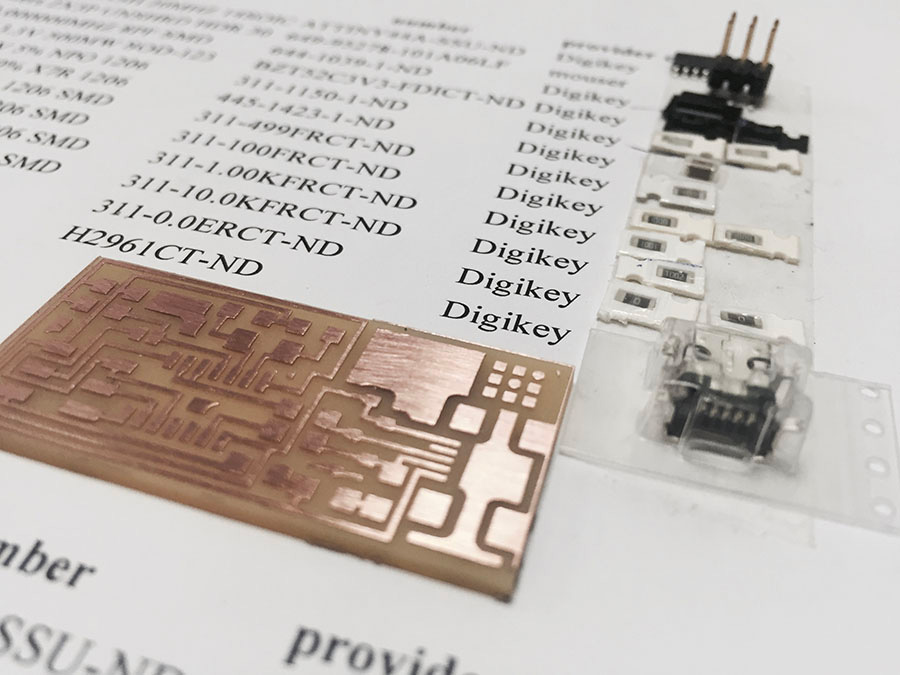

|fabricate PCB (FabISP)

|Assemble PCB

|Programming PCB

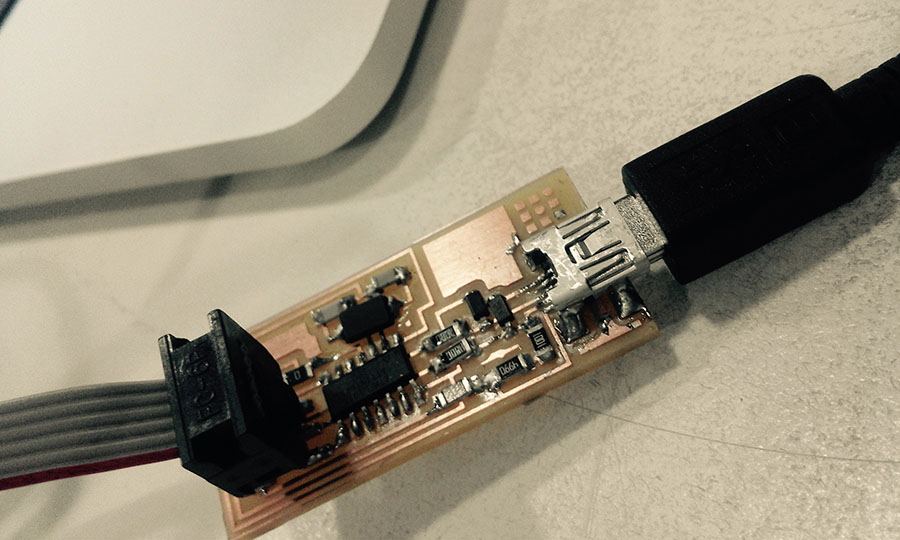

The FabISP is an alternative in-system programmer for AVR microcontrollers, designed for production within a FabLab; such as this . That is, it allows you to program the microcontrollers on other boards you make, using nothing but a USB cable and 6-pin IDC to 6-pin IDC cable.

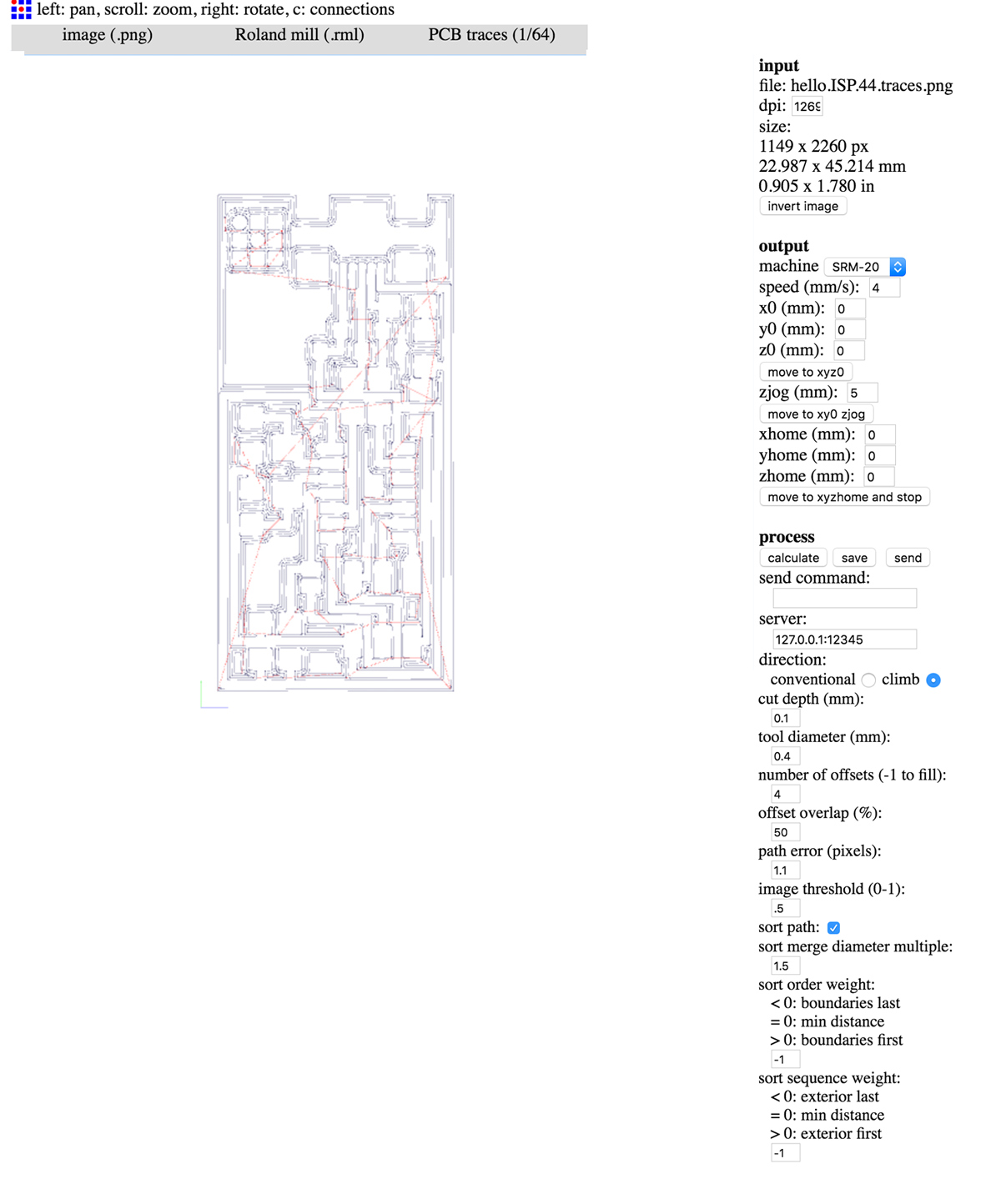

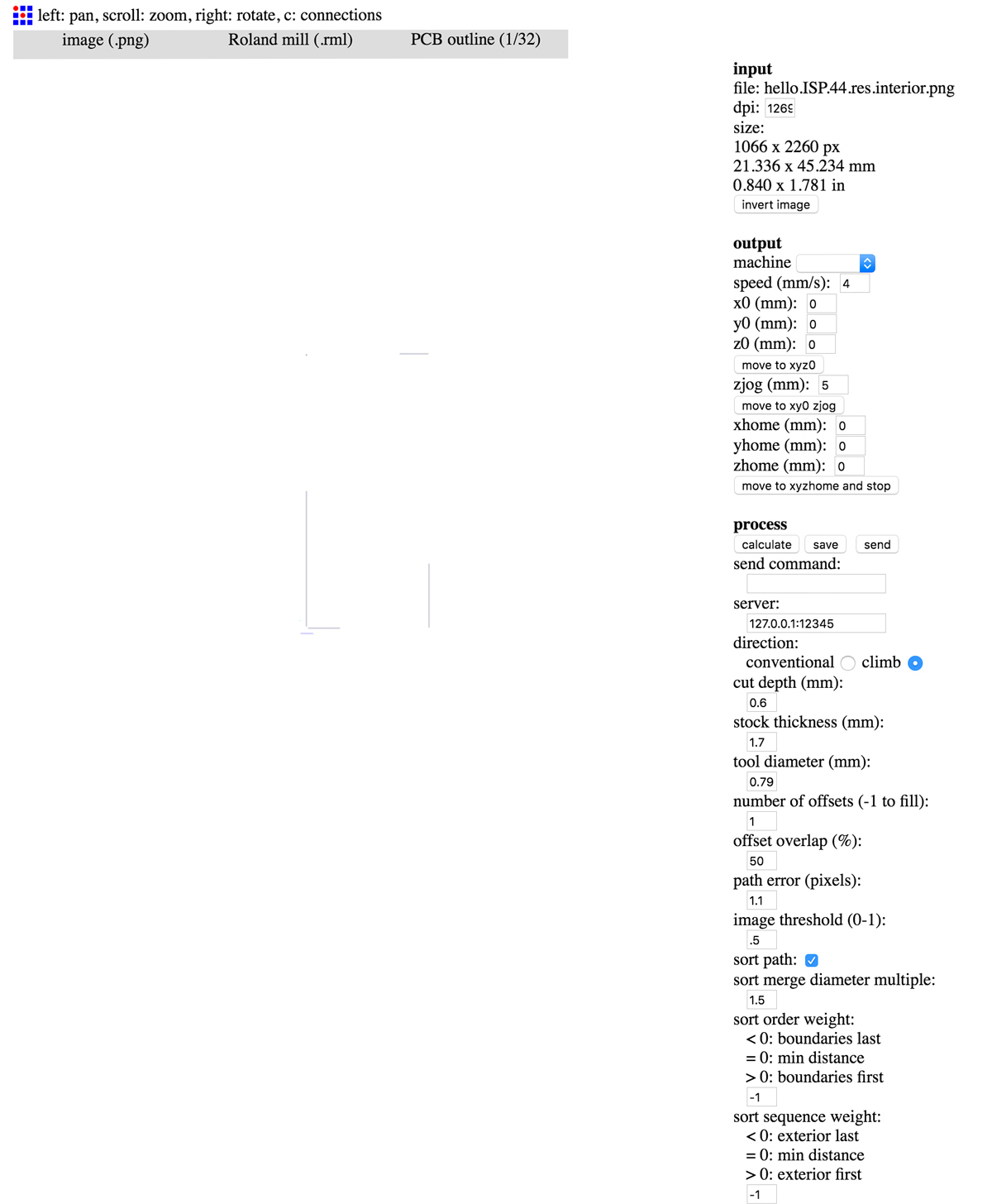

Fabmodules were used to generate the G-code for the Roland SRM-20 cnc-mill. The fab modules is an online program created to provide a set of software tools for personal fabrication, intended for use with machines common to fab labs.

traces for 64 bit

milling file for 64 bit

outline for 32 bit

milling file for 32 bit

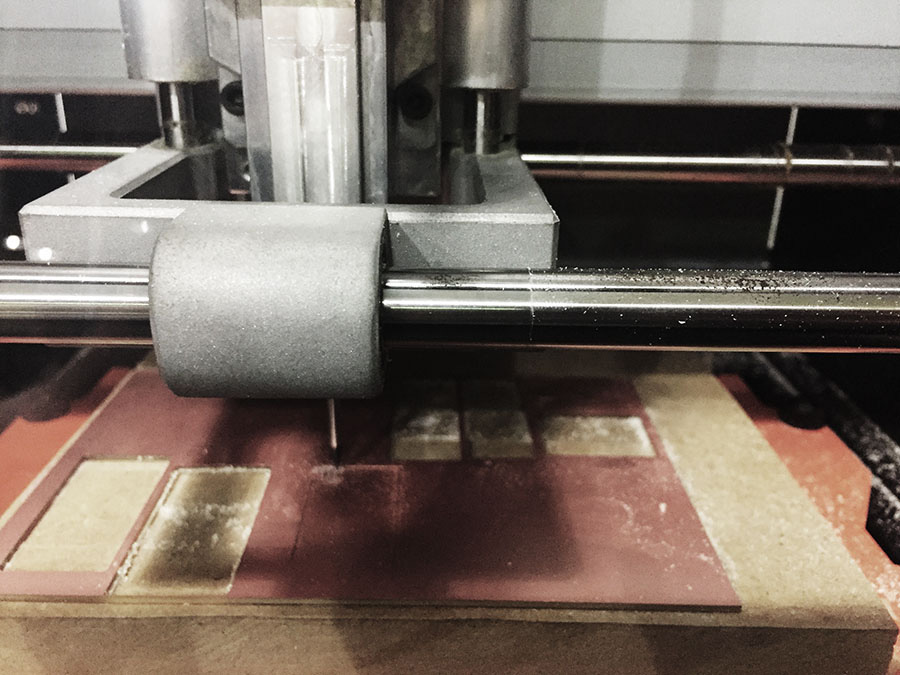

Before inputting data into fabmodules ; the cnc needed to be set. The PCB was checked for horizontality and well positioned with double sided tape. The 1/64" bit was placed to create the outline and the internal etch and outline. .bmp files were generated and placed in the roland interface.

The bit was thereafter replaced with the 1/32" bit to cut the final outline after a depth was established. Vertical Depths of 1mm were never exceeded in one go. Make sure you home at for example x0,y0, z5; not to screw up your board.

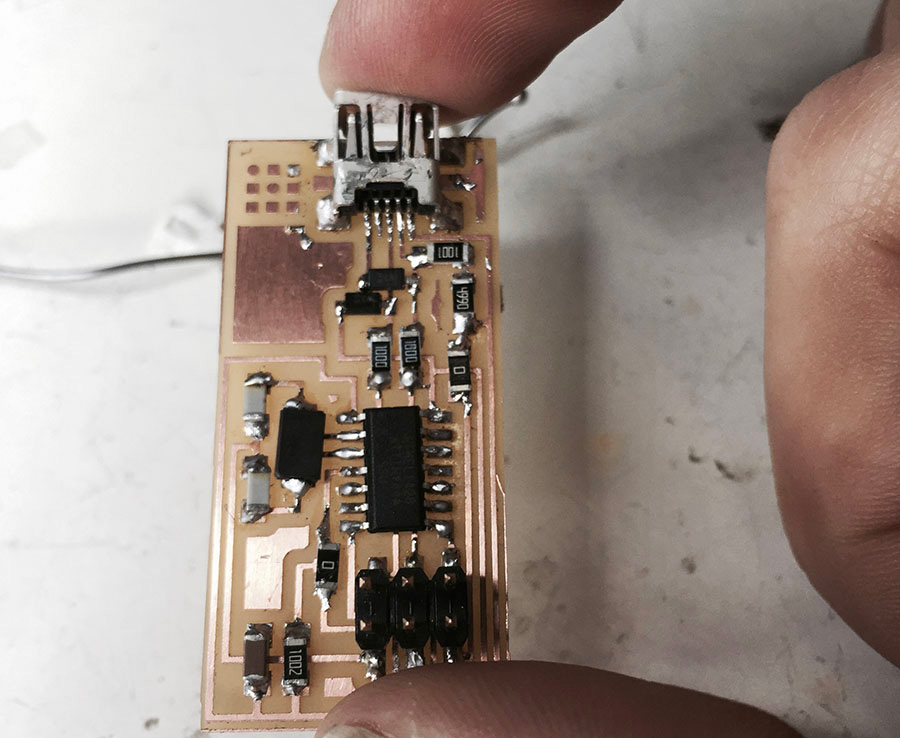

The inventory was used to collect the different parts which would then need to be soldered together. (Watch this soldering tutorial). Certain parts such as the micro- chips and diodes needed to be oriented correctly. Usb port needed to be placed properly by first connecting one corner then the rest to make sure alligned of inner small connections is perfect. I did not do this at first; so the allignment was incorrect. To correct it I placed more filament; heated it with the soldering iron and removed it- then placed it back. If this doesnt work one should use the heat gun. At times braid was also used to remove excess filament.

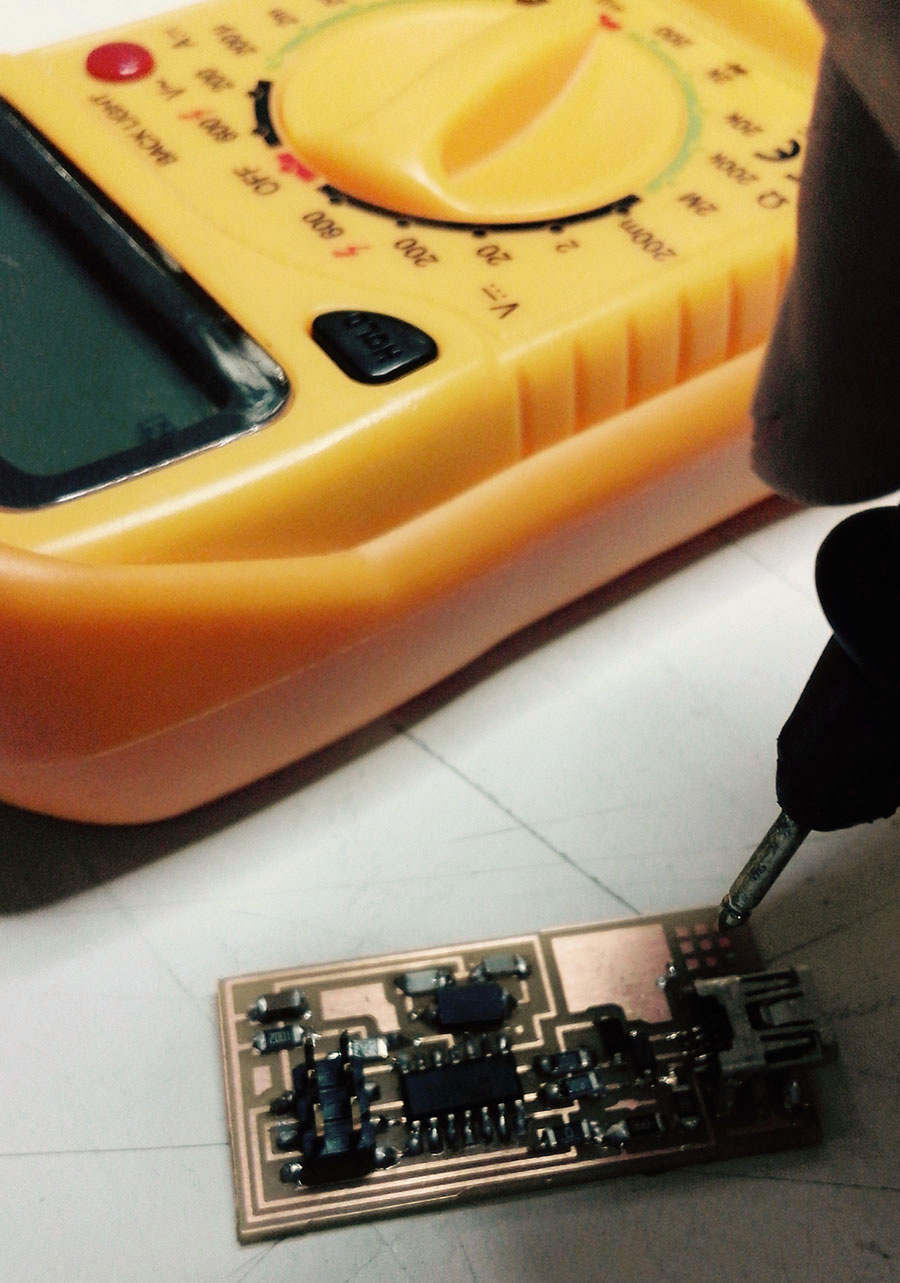

After soldering; a few checks were made; particularly with the micrometer. The digital multimeter(dmm) beeps if a complete path (continuity) is detected. If the circuit is open (the switch is in the OFF position), the DMM will not beep. Resistors were also checked to be reading approx 100 ohm.

PCB Programming was the next step. This took a few steps from the following tutorial. I was having few problems to program with el capitan on mac and had to use another laptop.

|Downloadfiles

|Brief MIT

|Lecture Neil Gershelfeld